Method for separating copper, bismuth and arsenic in high-acid waste liquor generated by copper anode slime treatment

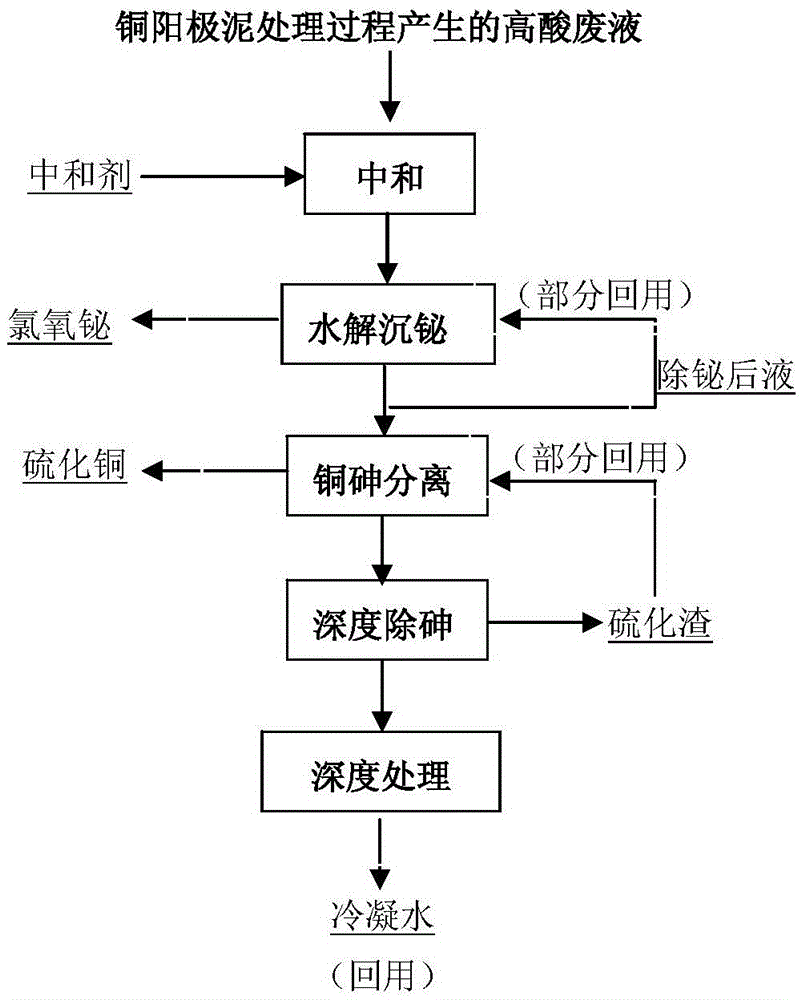

A technology for separating copper anode slime and arsenic, which is applied in the intersection of metallurgical engineering and environmental engineering, can solve problems such as difficulty in separating copper, bismuth, and arsenic, and achieve the effect of being beneficial to subsequent treatment, efficient separation and recovery, and reducing treatment procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

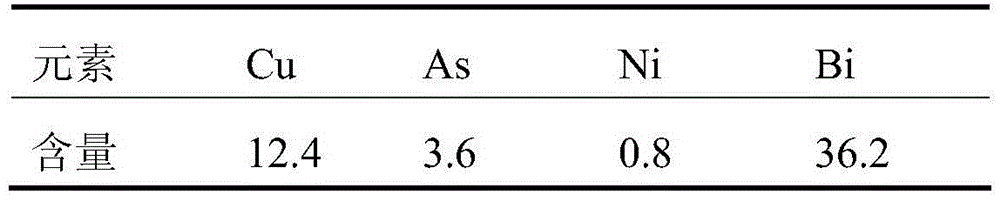

[0024] Take 500ml of high-acid waste liquid from the anode slime treatment of a copper smelter, H + The concentration is 4.0mol / L, other main elements and contents are as follows:

[0025] Table 1 Main elements and concentrations of high-acid waste liquid produced by anode slime treatment (g / L)

[0026]

[0027] Take the above high-acid waste liquid and add sodium carbonate to neutralize and hydrolyze to recover bismuth, control the pH value to 3.0, the reaction temperature is 50°C, and the reaction time is 30min. Oxybismuth slag, the content of bismuth in the slag is 67%, the content of bismuth in the filtrate is 20mg / L, and the recovery rate of bismuth is greater than 99%. Add arsenic sulfide slag to the solution after bismuth precipitation according to the As / Cu measurement ratio of 1.2:1, and react for 30 minutes to obtain high-grade copper sulfide slag with a copper content of 50%. The copper in the filtrate is less than 5mg / L. According to the S / As measurement ratio ...

Embodiment 2

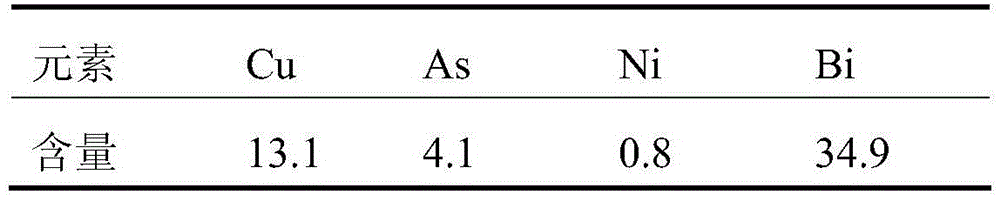

[0029] Take 500ml of high-acid waste liquid from the anode slime treatment of a copper smelter, H + The concentration is 4.2mol / L, other main elements and contents are as follows:

[0030] Table 2 Main elements and concentration of high-acid waste liquid produced by anode slime treatment (g / L)

[0031]

[0032] Take the above-mentioned high-acid waste liquid and add sodium carbonate to carry out neutralization and hydrolysis to recover bismuth, control the pH value to 3.0, the reaction temperature is 40°C, and the reaction time is 60min. Solid-liquid separation recovers bismuth oxychloride slag. The content of bismuth is 22mg / L, and the recovery rate of bismuth is greater than 99%. Add arsenic sulfide slag to the solution after bismuth precipitation according to the As / Cu measurement ratio of 1.3:1, and react for 60 minutes to obtain high-grade copper sulfide slag with a copper content of 51.3%. The copper in the filtrate is less than 5mg / L, and according to the S / As measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com