Method for preparing chlorogenic acid in Eucommia ulmoides leaves

A technology of Eucommia ulmoides leaves and chlorogenic acid, which is applied in chemical instruments and methods, separation/purification of carboxylate, preparation of carboxylate, etc. It can solve the problems of low product purity, large amount of waste water, low extraction rate of chlorogenic acid, etc. problems, to achieve the effect of simple membrane operation process, low water extraction temperature, and long-term stability of membrane flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

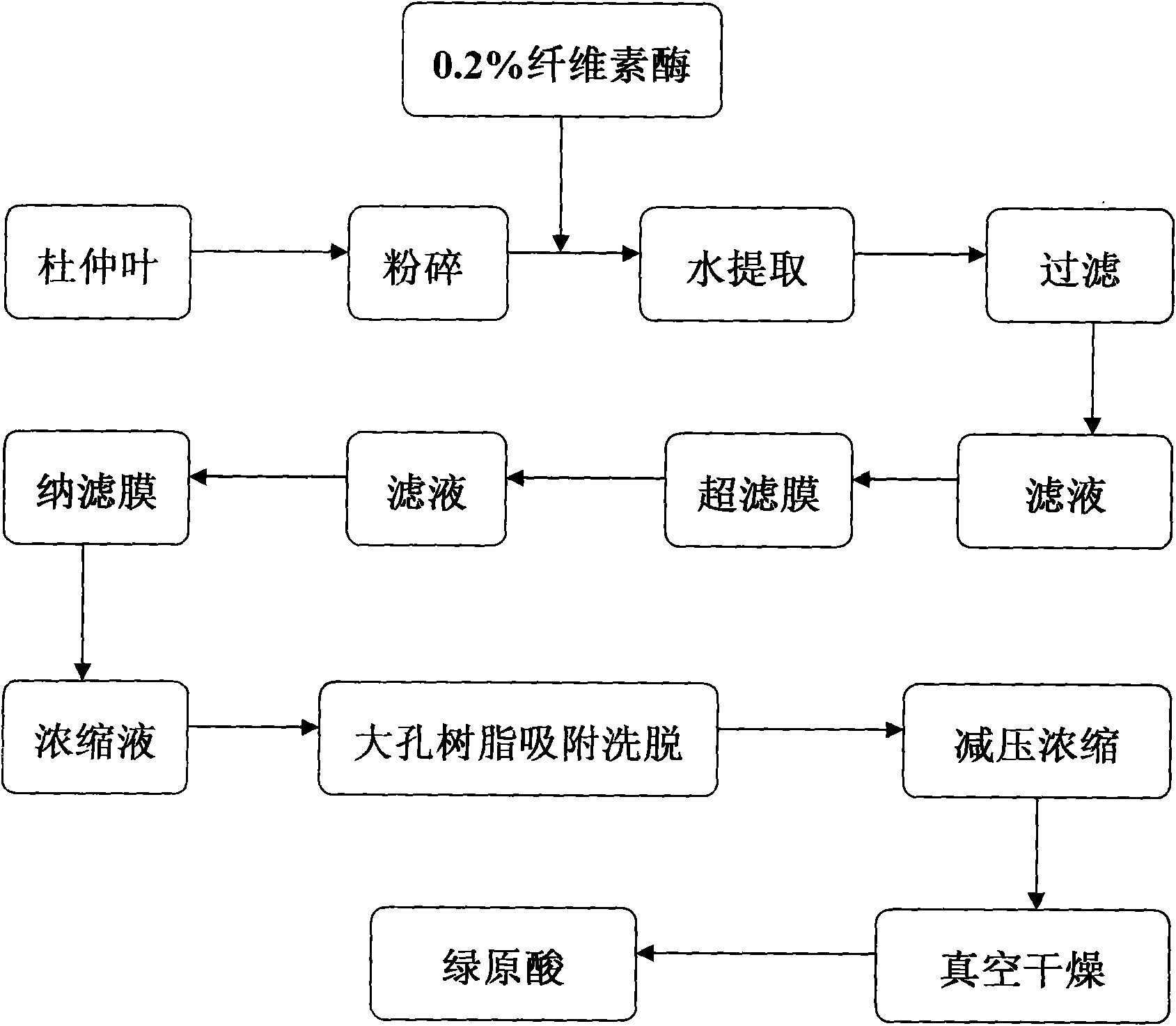

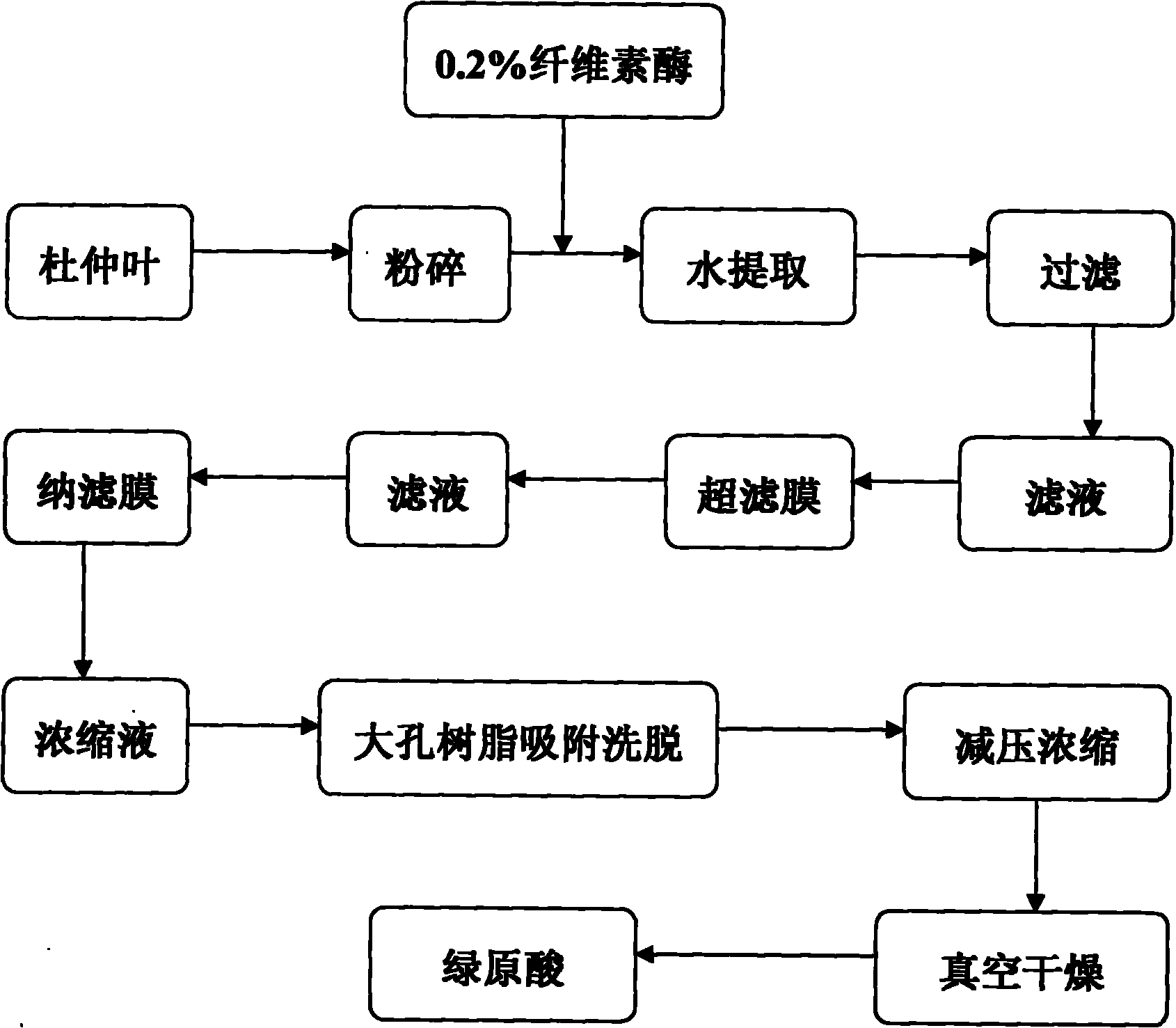

[0024] Example 1, see the attached figure 1 , take 10Kg of dried Eucommia leaves, crush them and pass through a 200-mesh sieve, add 120Kg of water, adjust the temperature to 55°C, keep the temperature constant and adjust the pH value to 4.5, then add 10g of cellulase, extract for 60min under this condition, filter, and filter the residue again Extract for the second time according to the aforementioned extraction conditions, combine the two filtrates, and filter conventionally, the extraction rate of chlorogenic acid is 95.8%; the operating conditions are P=0.3Mpa, T=45°C, PH=4.5, Q=70L / min filtrate After passing through a 0.03μm ultrafiltration membrane, the extract was concentrated 11.2 times under this condition, and the average flux of the ultrafiltration membrane was 226.3L / m 2 h; under the operating conditions P=1.5Mpa, T=50°C, PH=4.5, Q=20L / min, the ultrafiltration filtrate is passed through a 200 molecular weight nanofiltration membrane, and the ultrafiltration filtrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com