Method for simultaneously preparing chlorogenic acid and luteoloside from honeysuckle flower

A technology of luteolin and chlorogenic acid, which is applied to chemical instruments and methods, preparation of carboxylic acid esters, preparation of sugar derivatives, etc., can solve the problems of complex process, cumbersome separation steps, high equipment cost, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

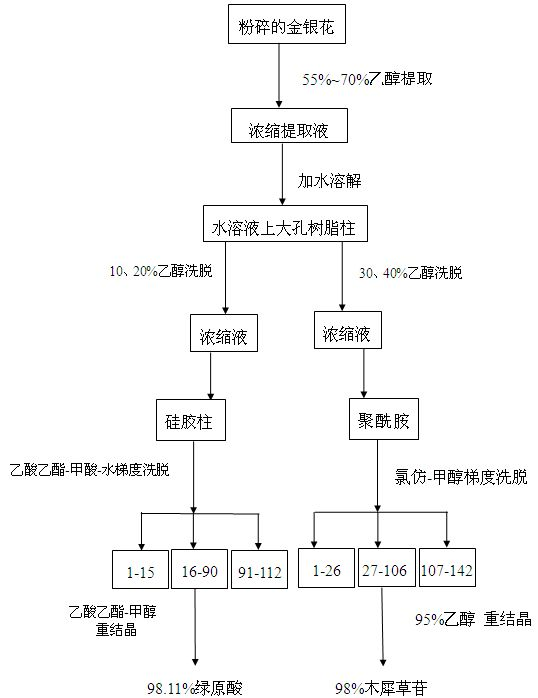

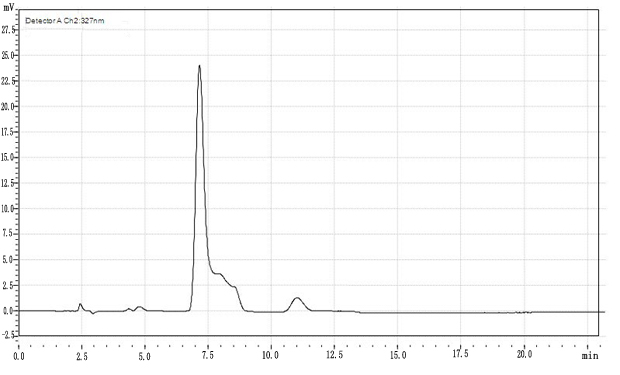

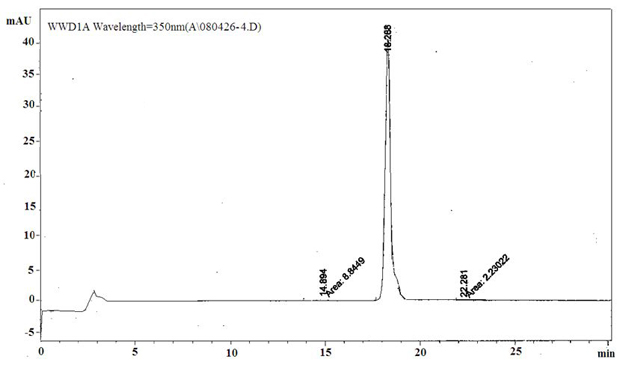

[0034]Take 500 g of honeysuckle dry powder, add 10 L of ethanol with a mass fraction of 60%, ultrasonically extract 3 times, each time for 30 minutes, combine the extracts, filter the extracts and remove the filter residue, concentrate the filtrate to a brown-red viscous extract; Dissolve the extract in 6 deionized water for 3 times, filter, and pass the filtrate through a D101 macroporous resin column at a flow rate of 3 times the column volume / hour, absorb for 10 hours, and elute with deionized water for 3 hours at a flow rate of 4 times the column volume / hour , and then eluted with 10% ethanol with a mass fraction of pH=6, 20% ethanol with a mass fraction of 20% ethanol at a flow rate of 2 times column volume / hour for 3 h, and then eluted with 30% ethanol with a mass fraction of pH=6, The mass fraction of 40% ethanol was eluted at a flow rate of 2 times column volume / hour for 4 hours, and finally 95% mass fraction of ethanol was used for elution at a flow rate of 5 times col...

Embodiment 2

[0038] Take 500 g of honeysuckle dry powder, add 15 L of ethanol with a mass fraction of 70%, ultrasonically extract 3 times, each time for 30 minutes, combine the extracts, filter the extracts and remove the filter residue, concentrate the filtrate to brown-red viscous extract, use pH = 6 deionized water to dissolve the extract for 3 times, filtered, and the filtrate passed through the D101 macroporous resin column at a flow rate of 3 times column volume / hour, adsorbed for 9 hours, and eluted with deionized water at a flow rate of 4 times column volume / hour for 2.5 h, then elute with 10% ethanol with a mass fraction of pH=6 and 20% ethanol with a mass fraction of 20% at a flow rate of 3 times column volume / hour for 3 h, and then use 30% ethanol with a mass fraction of pH=6 and 40% ethanol at a flow rate of 2.5 column volumes / hour for 4 hours, and finally 95% ethanol at a flow rate of 5 column volumes / hour for 4 hours.

[0039] The ethanol eluate with a mass fraction of 10% an...

Embodiment 3

[0042] Refer to attached figure 1 , take 800g of honeysuckle dry powder, add 12L of ethanol with a mass fraction of 65%, ultrasonically extract 3 times, each time for 30min, combine the extract, remove the filter residue after filtering the extract, concentrate the filtrate to brown-red viscous extract, use pH =6 deionized water to dissolve the extract for 3 times, filter, and the filtrate passes through a D101 type macroporous resin column at a flow rate of 3 times column volume / hour, absorb for 11 hours, and elute with deionized water at a flow rate of 4 times column volume / hour 3h, then elute with 10% ethanol with a mass fraction of pH=6 and 20% ethanol with a mass fraction of 20% at a flow rate of 3 times column volume / hour for 4h, and then use 30% ethanol with a mass fraction of pH=6 and 40% ethanol at a flow rate of 3 column volumes / hour for 3 hours, and finally with 95% ethanol at a flow rate of 5 column volumes / hour for 4 hours.

[0043] The ethanol eluate with a mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com