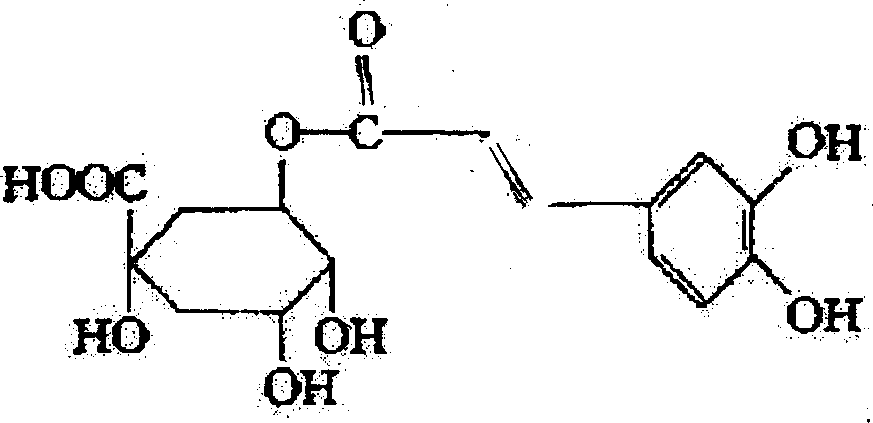

Chlorogenic acid extracting and purifying process from sunflower seed dregs

A technology of sunflower meal and chlorogenic acid, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., to achieve the effect of improving extraction rate and good appearance and color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

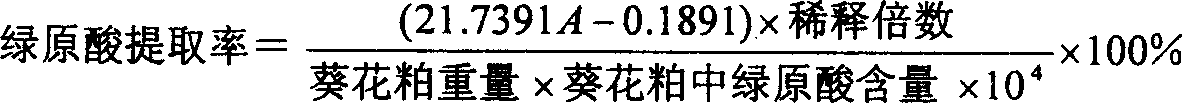

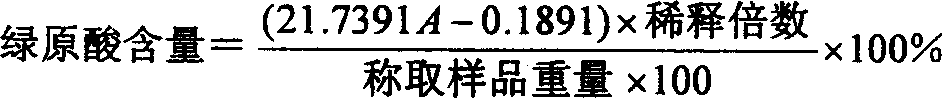

[0028] Embodiment 1 Weigh 5 parts of 5 grams of sunflower meal, the chlorogenic acid content in the sunflower meal used is 3.13% (the same below), add 70% ethanol according to the ratio of material to liquid 1: 12, and adjust the pH of the solution to be 2.5, 4.5 respectively , 6.5, 8.5, 10.5, heated under reflux at 50°C for 3h, extracted once, there is a weighing error of 5g sample, take 50ul sample solution during measurement, use paper chromatography, and then use 10ml 50% methanol solution to dissolve chlorogenic acid, Therefore, the dilution factor is 200 (the same below),

[0029] Extract pH

Embodiment 2

[0031] Extraction temperature (℃)

Embodiment 3

[0033] solid-liquid ratio

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com