Novel method for adsorption separation of high purity chlorogenic acid

A technology of adsorption separation and chlorogenic acid, which is applied in chemical instruments and methods, preparation of carboxylic acid esters, preparation of organic compounds, etc., can solve the problems of low utilization rate and discontinuity of upper column liquid and eluent, and achieve No environmental pollution, easy to transport, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

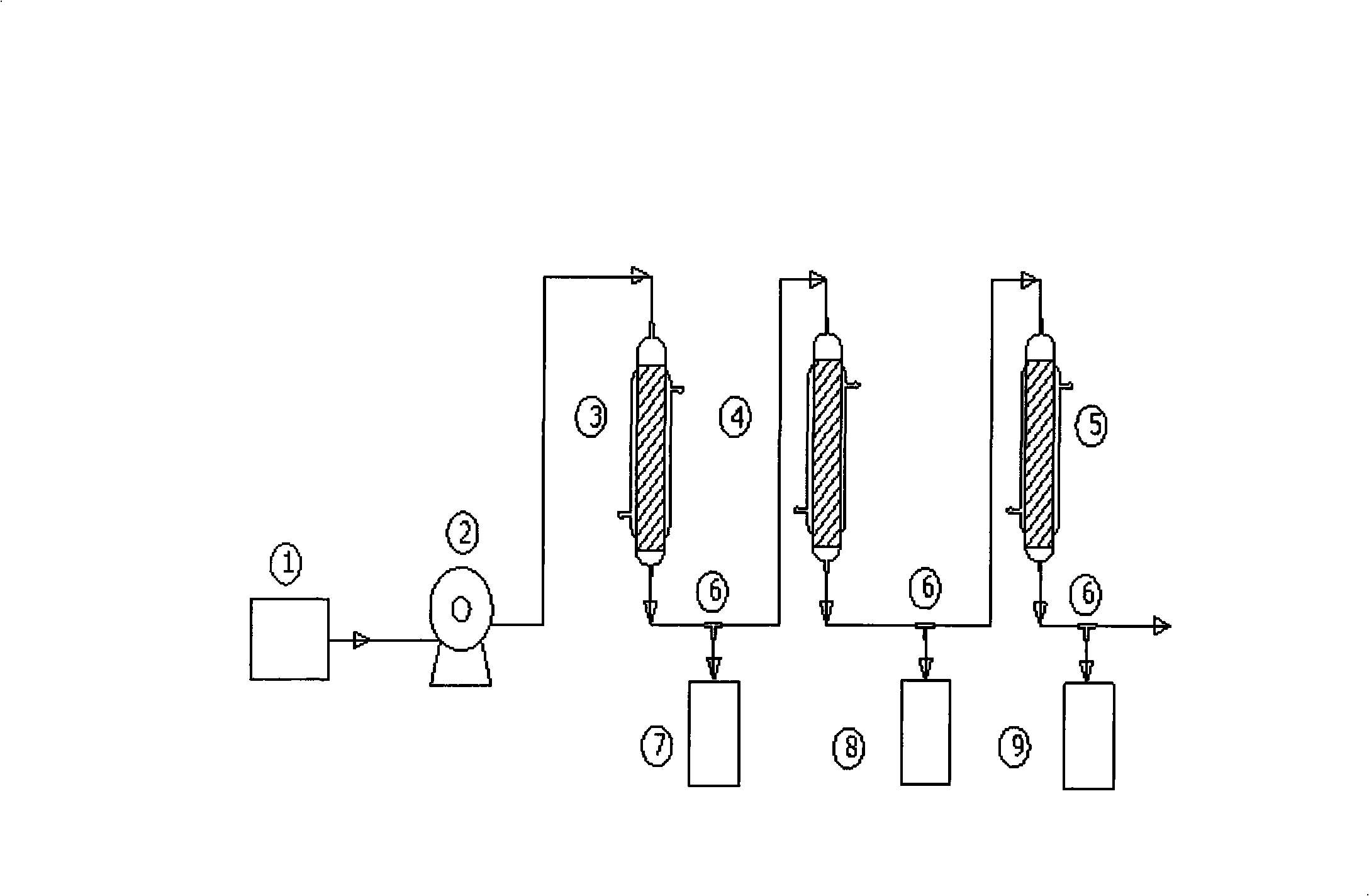

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, the honeysuckle water extraction stock solution with a pH value of 6 and a concentration of 5.0 mg / mL is used. The series of adsorption columns is three stages, and the adsorption columns at each level are glass columns with a height-to-diameter ratio of 1:10 (Φ15×150mm). Pack non-polar macroporous adsorption resin XDA-1 (Xi'an Electronic Resin Factory).

[0039] The original solution passes through the first-level adsorption column 10BV, the second-level adsorption column 8BV, and the third-level adsorption column 10BV in sequence, so that each column reaches the breakthrough point, and the flow rate of the solution is controlled to be 12BV / h. The first-level adsorption column, the second-level adsorption column, The column temperature of the tertiary adsorption column is 25°C. Choose water as the washing liquid, wash the primary adsorption column 4BV, the secondary adsorption column 2BV, and the tertiary adsorption column 4BV in sequence, and the e...

Embodiment 2

[0041]In this example, the tobacco water extraction stock solution with a pH value of 7 and a concentration of 4.0 mg / mL is used. The series of adsorption columns is three stages, and the adsorption columns at each level are resistant to organic solvents with a height-to-diameter ratio of 1:4 (Φ15×60mm). The column was filled with medium polar macroporous adsorption resin HZ-806 (Shanghai Huazhen Technology Co., Ltd.).

[0042] The original solution passes through the primary adsorption column 2BV, the secondary adsorption column 1BV, and the tertiary adsorption column 2BV in sequence, so that each column reaches the breakthrough point, the flow rate of the solution is controlled to be 5BV / h, and the primary adsorption column, the secondary adsorption column, The column temperature of the tertiary adsorption column is 25°C. Choose 50% ethanol aqueous solution as the washing liquid, wash the primary adsorption column 0.5BV, the secondary adsorption column 0.5BV, and the tertiar...

Embodiment 3

[0044] In this example, Eucommia ulmoides water extraction stock solution with a pH value of 6 and a concentration of 2.0 mg / mL was used. Stainless steel column, filled with weak polar macroporous adsorption resin XDA-5 (Xi'an Electronic Resin Factory).

[0045] The original solution passes through the primary adsorption column 7BV and the secondary adsorption column 4BV in sequence, so that each column reaches the breakthrough point, the flow rate of the solution is controlled to 15BV / h, and the column temperature of the primary adsorption column and the secondary adsorption column is controlled at 25°C. Choose 1M hydrochloric acid aqueous solution as the washing liquid, wash the primary adsorption column 2BV, and the secondary adsorption column 1BV in sequence, and the elution flow rate is 15BV / h, until the effluent is sugar-free and protein-free. Then use acetone with a pH value of 5 to dynamically elute the primary adsorption column 5BV and the secondary adsorption column ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com