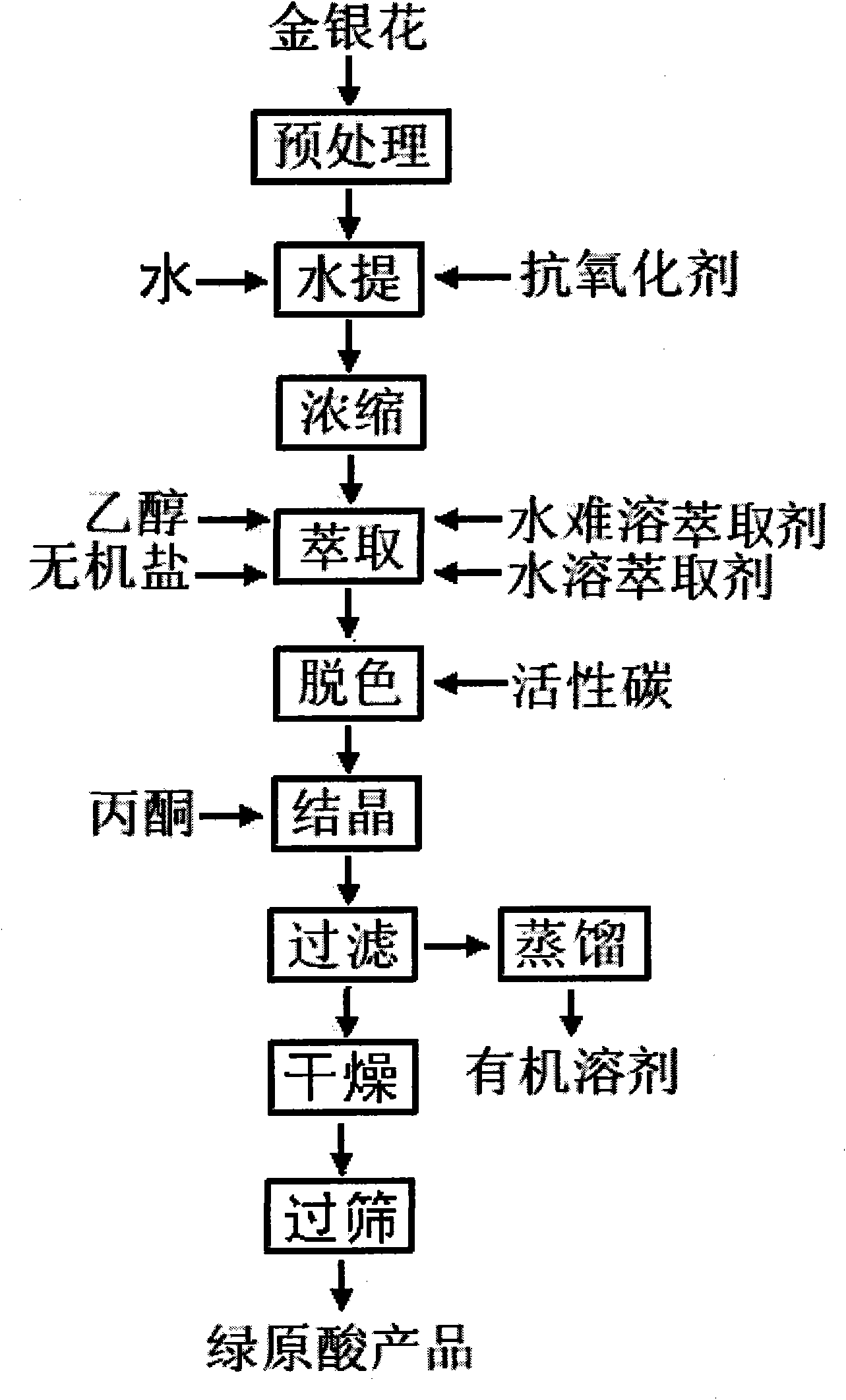

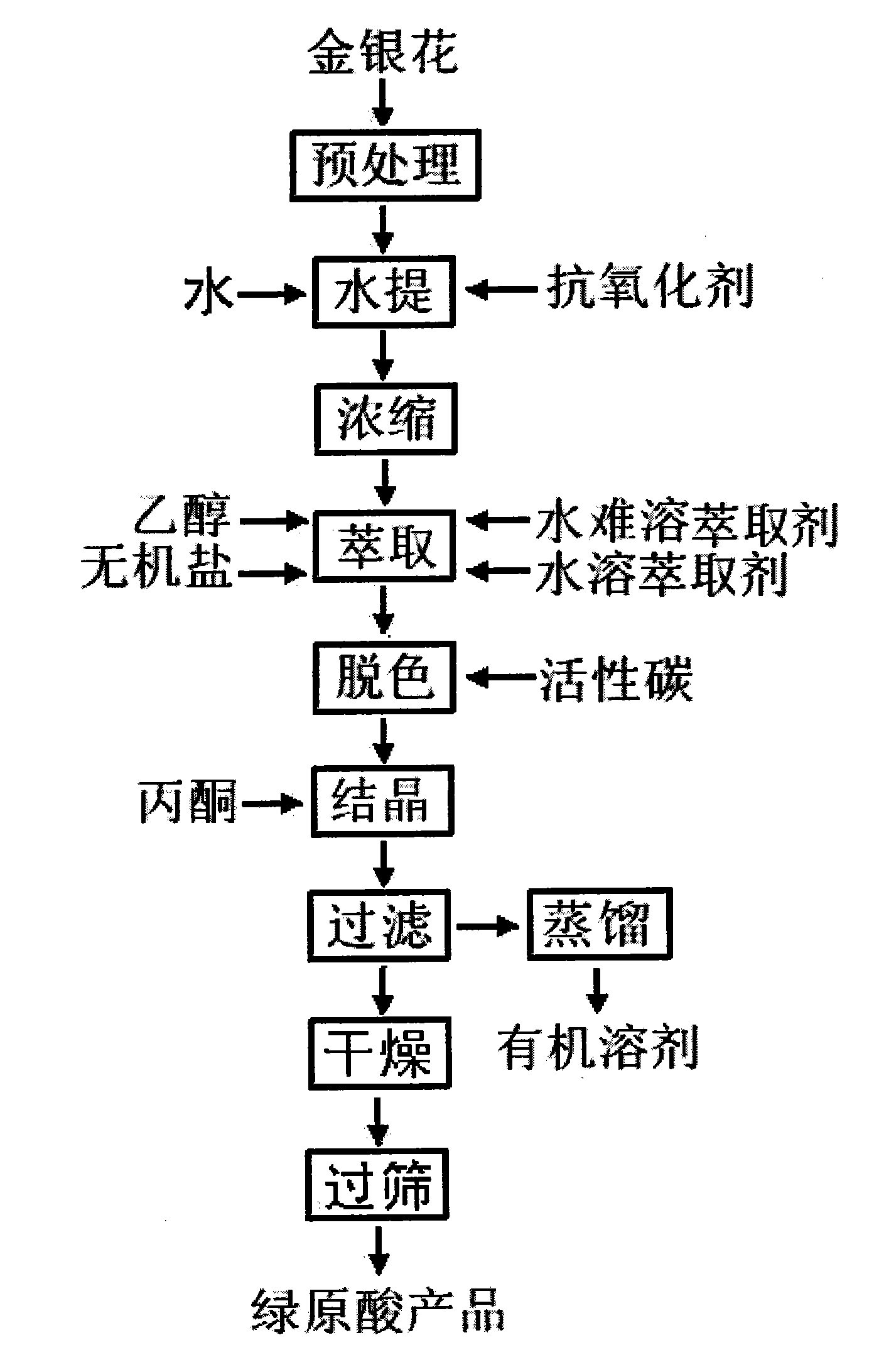

Method for preparing honeysuckle chlorogenic acid

A technology of honeysuckle chlorogenic acid and honeysuckle, applied in the separation/purification of carboxylic acid esters, organic chemistry, etc., can solve the problems of unsatisfactory separation effect of chlorogenic acid, long process flow, difficult filtration, etc., and achieve easy continuous production operation , short process flow and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Add 5 parts by weight of dried honeysuckle flowers and leaves and branches of raw materials that have been removed, coarsely crushed or cut into sections into a stainless steel reaction tank, add deionized water in a ratio of 1:3 parts by weight of raw materials and water, and add the antioxidant sodium bisulfite The usage amount is 1.0 / 10,000 of the total feeding amount, the pH value is adjusted to 3.2, the extraction is heated and kept for three times, the temperature is controlled at 65-67°C, the holding time is 1.2h, and the extracts are combined. Then the extract is introduced into a stainless steel reaction tank for concentration under reduced pressure, the temperature is controlled to be ≤60°C, the vacuum degree is ≥0.08MPa, and concentrated into an extract of 8 degrees Baume. Then the concentrated extract is added in a stainless steel reaction kettle, ethanol with 180 times the weight of the raw material honeysuckle is added, and 40 parts by weight of inorganic s...

Embodiment 2

[0042] Add 5 parts by weight of dried gold and silver flowers that have been removed, coarsely crushed or cut into sections into an aluminum alloy reaction tank, add deionized water in a ratio of 1:3 parts by weight of raw materials and water, and add antioxidant sodium bisulfite to The total feeding amount is 1.4 / 10,000, the pH value is adjusted to 3.2, heating and heat preservation is carried out for three times for extraction, the temperature is controlled at 67-69°C, the heat preservation time is 1-1.5h, and the extracts are combined. Then the extract is introduced into an enamel reaction kettle for concentration under reduced pressure, the temperature is controlled to be ≤60°C, the vacuum degree is ≥0.08MPa, and concentrated into an extract of 7.8 degrees Baume. Then put the concentrated extract into the enamel reaction kettle, add 200 parts by weight of raw material honeysuckle ethanol, 0.113 parts by weight of methyl polypropylene glycol, and add 40 parts by weight of in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com