Separation equipment and separation method of methyl methacrylate (MMA)

A technology of methyl methacrylate and separation equipment, which is applied in the separation/purification of carboxylate, preparation of carboxylate, chemical instruments and methods, etc. It can solve the problems of not recycling other products and achieve high utilization rate , Low energy consumption, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

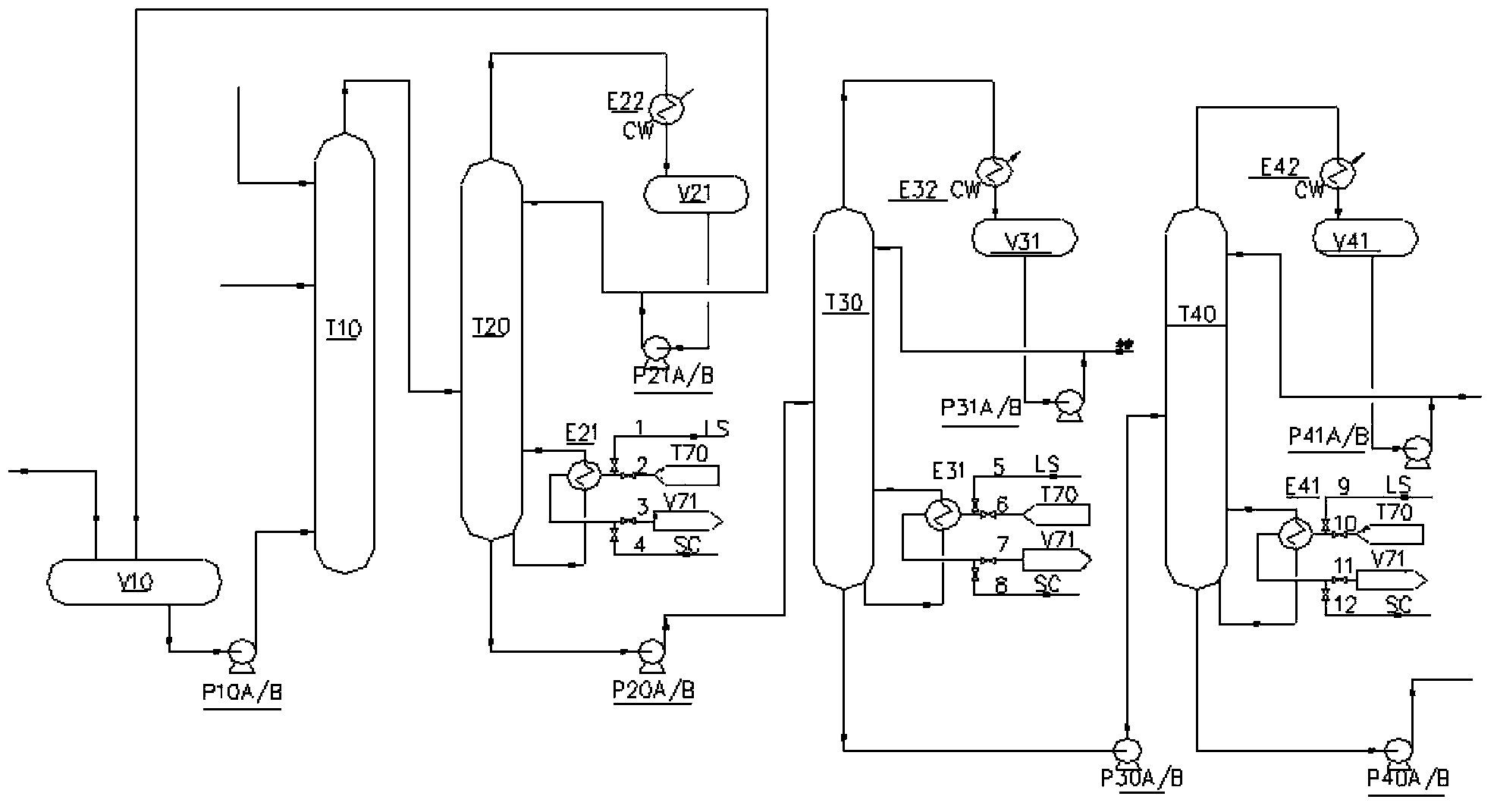

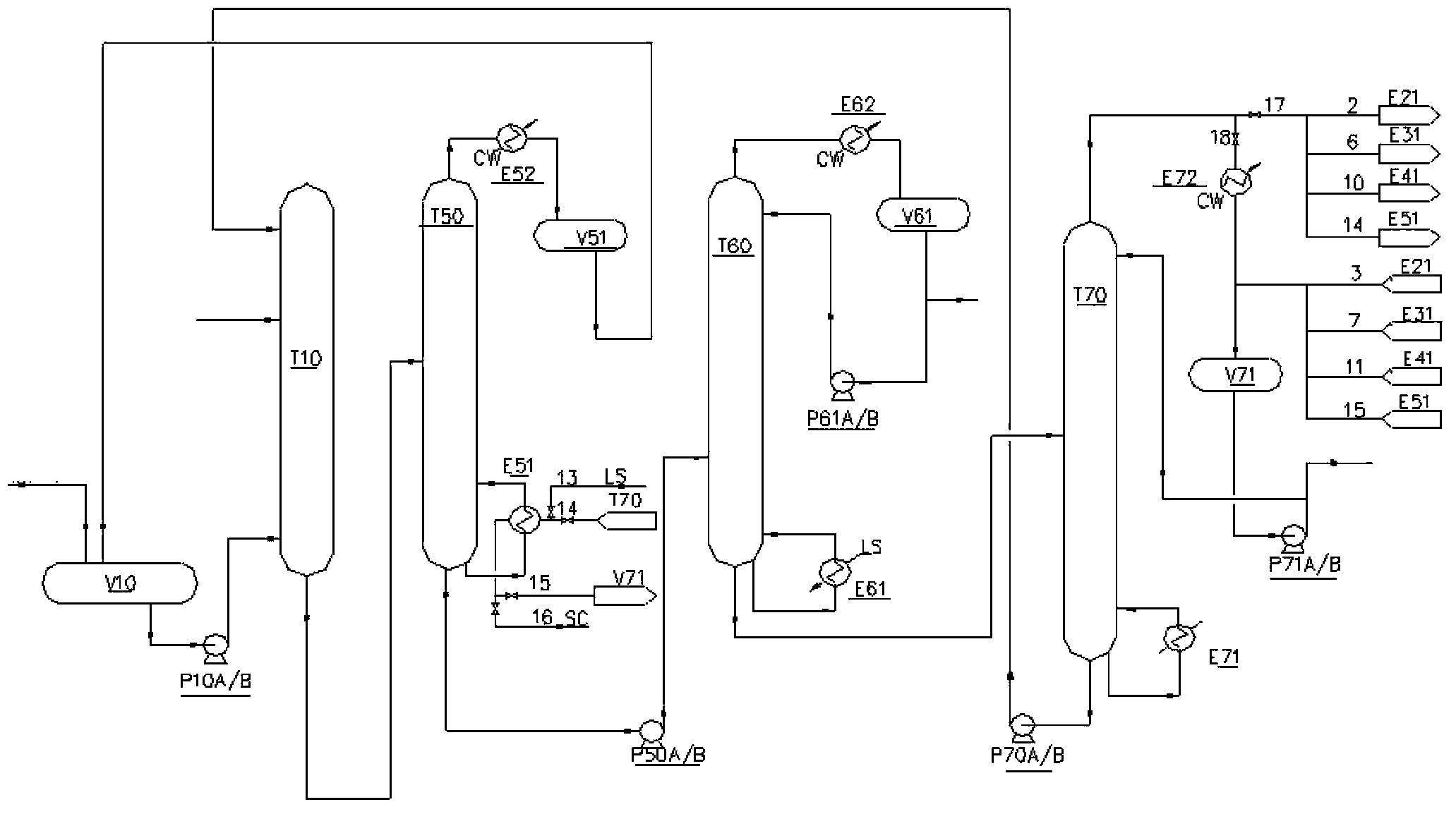

[0096] MMA reaction section: the isobutene or tert-butanol extracted from the mixed carbon four is used as the raw material for producing MMA, and enters the first reactor to react with methanol to obtain methacrolein. The reaction is carried out at 0.1MPa~0.2MPa, and the mass content is obtained. 20% methacrolein reaction solution. The methacrolein reaction liquid is refined through a methanol absorption tower, a washing tower, and an aldehyde rectification tower to obtain a methacrylic acid liquid with a mass content of 40%. The 40% methacrylic acid liquid was further reacted with methanol in the second reactor to obtain a methyl methacrylate reaction liquid with a mass content of 31%. 31% of the methyl methacrylate reaction solution enters the MMA separation process for purification.

[0097] Separation process of MMA reaction liquid: 31% methyl methacrylate reaction liquid enters the high-efficiency packed extraction tower T10 with a theoretical plate number of 13 and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com