Method for separating methyl-acrolein in methyl-methyl acrylate

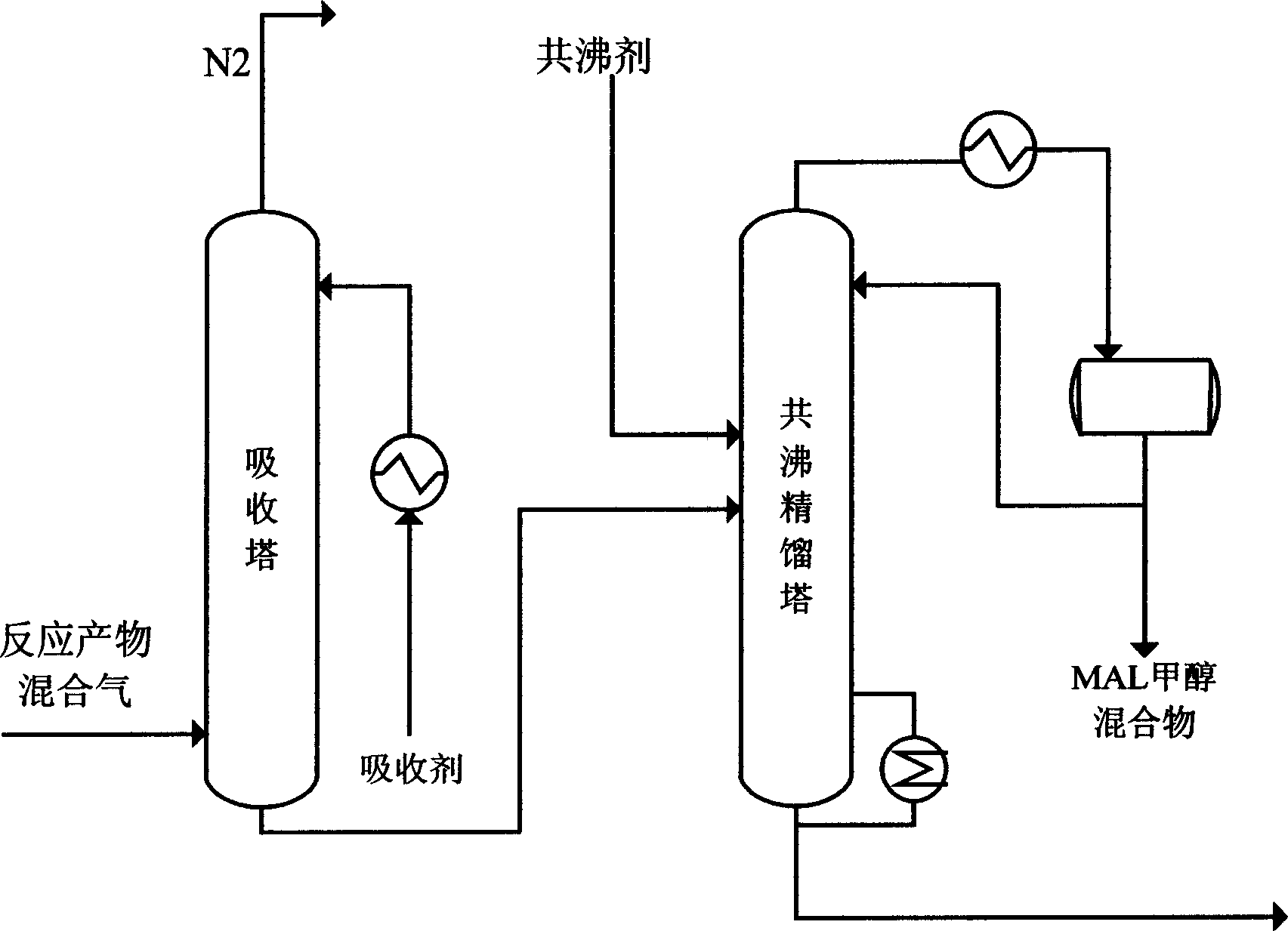

A technology of methyl methacrylate and methacrolein, which is applied in the field of absorption and separation of volatile polymerized monomers, can solve the problems that cannot meet the requirements of the second-step oxidative esterification reaction, MAL separation is difficult, and can not meet the requirements, so as to reduce the Equipment investment and operating costs, the effect of solving high water content and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0006] Embodiment 1: a kind of technological operation parameter of MAL separation and purification in the product gas mixture

[0007] The reaction product gas stream is flowed into the water absorption tower, and the number of trays is 10, operated at normal pressure, 110 ° C of the inlet product gas temperature, and the gas composition is 0.22% of IB (isobutylene), O 2 1.51%, N 2 68.11%, H 2 O 12.30%, CO 2 4.25%, CO 1.77%, MAL 10.97%, MAA 0.50%, C 3 h 6 O 0.1%, mass flow rate is 15.44kg / h, absorbing with 2°C water 42.00kg / h, tower bottom temperature 44.6°C, tower top temperature 2.3°C. The composition of the overhead gas after absorption is IB 0.03%, O 2 1.96%, N 2 89.6%, H 2 O 0.5%, CO 2 5.5%, CO 2.32%, MAL trace, C 3 h 6 O trace.

[0008] Put the MAL aqueous solution and methanol into the rectification tower. The rectification tower has 25 plates. It operates under normal pressure. The feeding position is 13 plates. The temperature of the inlet material i...

Embodiment 2

[0009] Embodiment 2: another kind of technological operation parameter of MAL separation and purification in the product gas mixture

[0010] The gas flow of the reaction product flows into the water absorption tower, the number of trays is 10, the normal pressure is operated, the inlet product gas temperature is 130°C, and the gas composition is IB 0.22%, O 2 1.51%, N 2 68.11%, H 2 O 12.30%, CO 2 4.25%, CO 1.77%, MAL 10.97%, MAA 0.50%, C 3 h 6 O 0.1%, the mass flow rate is 15.44kg / h, absorbing with 20°C water 48.00kg / h, the temperature of the bottom of the tower is 52.0°C, and the temperature of the top of the tower is 22.3°C. The composition of the overhead gas after absorption is IB 0.20%, O 2 1.97%, N 2 85.20%, H 2 O 1.7%, CO 2 5.21%, CO2.12%, MAL 3.4%, C 3 h 6 O trace.

[0011] Put the MAL aqueous solution and methanol into the rectification tower. The rectification tower has 25 plates. It operates under normal pressure. The feeding position is 13 plates. ...

Embodiment 3

[0012] Embodiment 3: the third process operation parameter of MAL separation and purification in product gas mixture

[0013] The gas flow of the reaction product flows into the water absorption tower, the number of trays is 10, the operating pressure is 2atm, the inlet product gas temperature is 120°C, and the gas composition is IB 0.22%, O 2 1.51%, N 2 68.11%, H 2 O 12.30%, CO 2 4.25%, CO 1.77%, MAL 10.97%, MAA 0.50%, C 3 h 6 O 0.1%, the mass flow rate is 15.44kg / h, absorbing with 42.00kg / h of water at 10°C, the temperature of the bottom of the tower is 52.2°C, and the temperature of the top of the tower is 10.5°C. The tower top gas composition after absorbing is IB trace, O 2 2%, N 2 90.00%, H 2 O 0.4%, CO 2 5.21%, CO 2.30%, MAL 0.23%, C 3 h 6 O 0.004%.

[0014] Put the MAL aqueous solution and methanol into the rectification tower, the rectification tower has 25 plates, operates under normal pressure, the feed position is 10 plates, the inlet material temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com