Process for producing furfural by bagasse

A technology of bagasse and furfural, which is applied in dryers, drying, organic chemistry, etc., can solve the problems of difficult slag discharge and has not been used in mass production, so as to reduce the trouble of slag removal, shorten the reaction time, and slag discharge smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

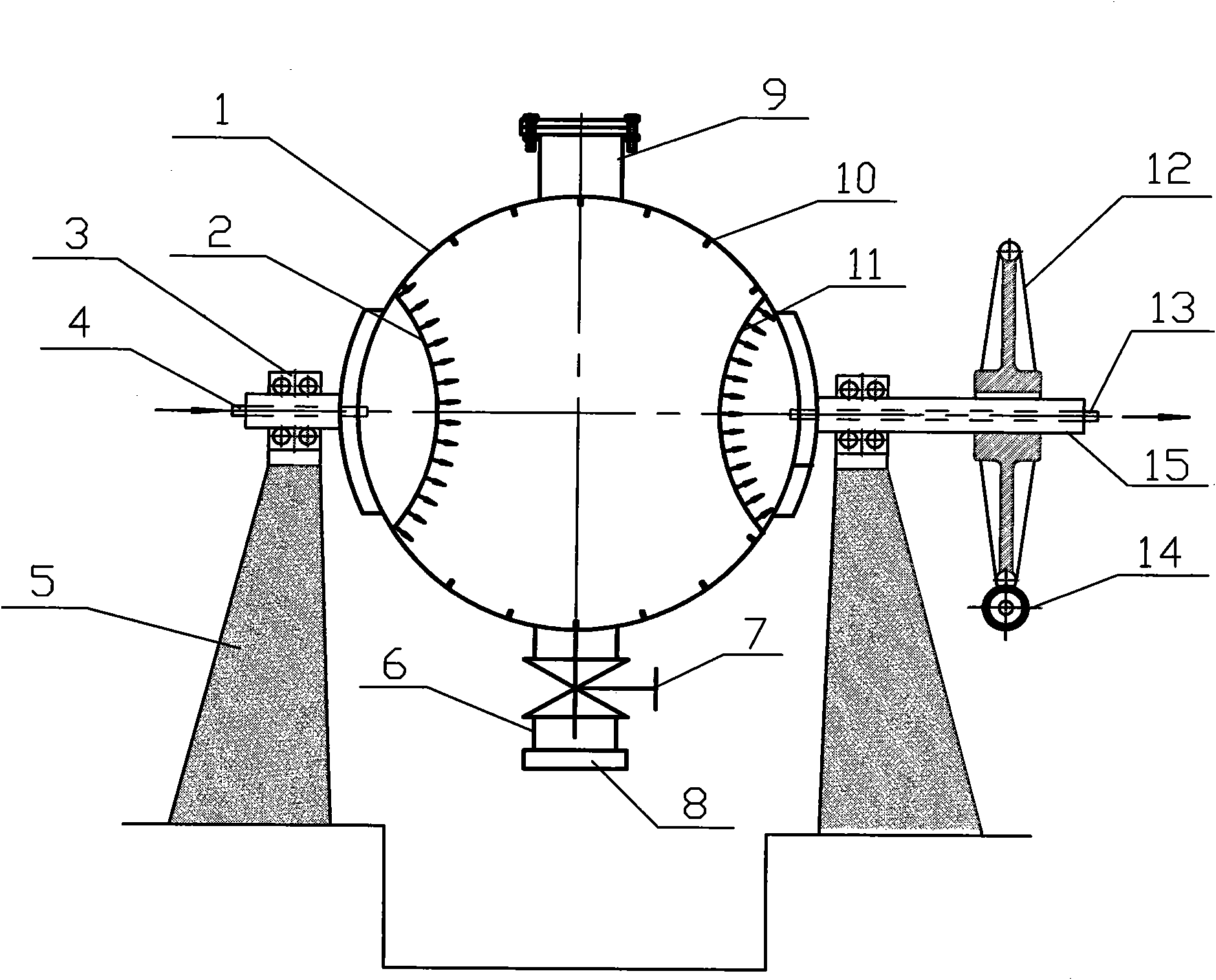

[0018] The structure of steaming ball of the present invention is as figure 2 As shown, its structure includes a housing 1 and a rotating device. The two ends of the housing 1 are respectively welded with a shaft head 15. The shaft head 15 is provided with a bearing 3, and the lower part of the bearing 3 is provided with a support 5. , the rotating device is connected to one end of the shaft head 15, and the central holes of the shaft head 15 at both ends are the steam inlet hole 4 and the steam exhaust hole 13 respectively, and the steam inlet hole 4 and the steam exhaust hole 13 communicate with the housing 1 , the housing 1 corresponding to the steam inlet 4 is provided with a steam inlet pan 2 with a steam outlet, and the housing 1 corresponding to the steam outlet 13 is provided with a receiving pan with a steam outlet Steam tray 11, the top of the shell 1 is provided with a charging port 9, the bottom of the shell 1 is provided with a slag discharge port 6, the slag dis...

Embodiment 2

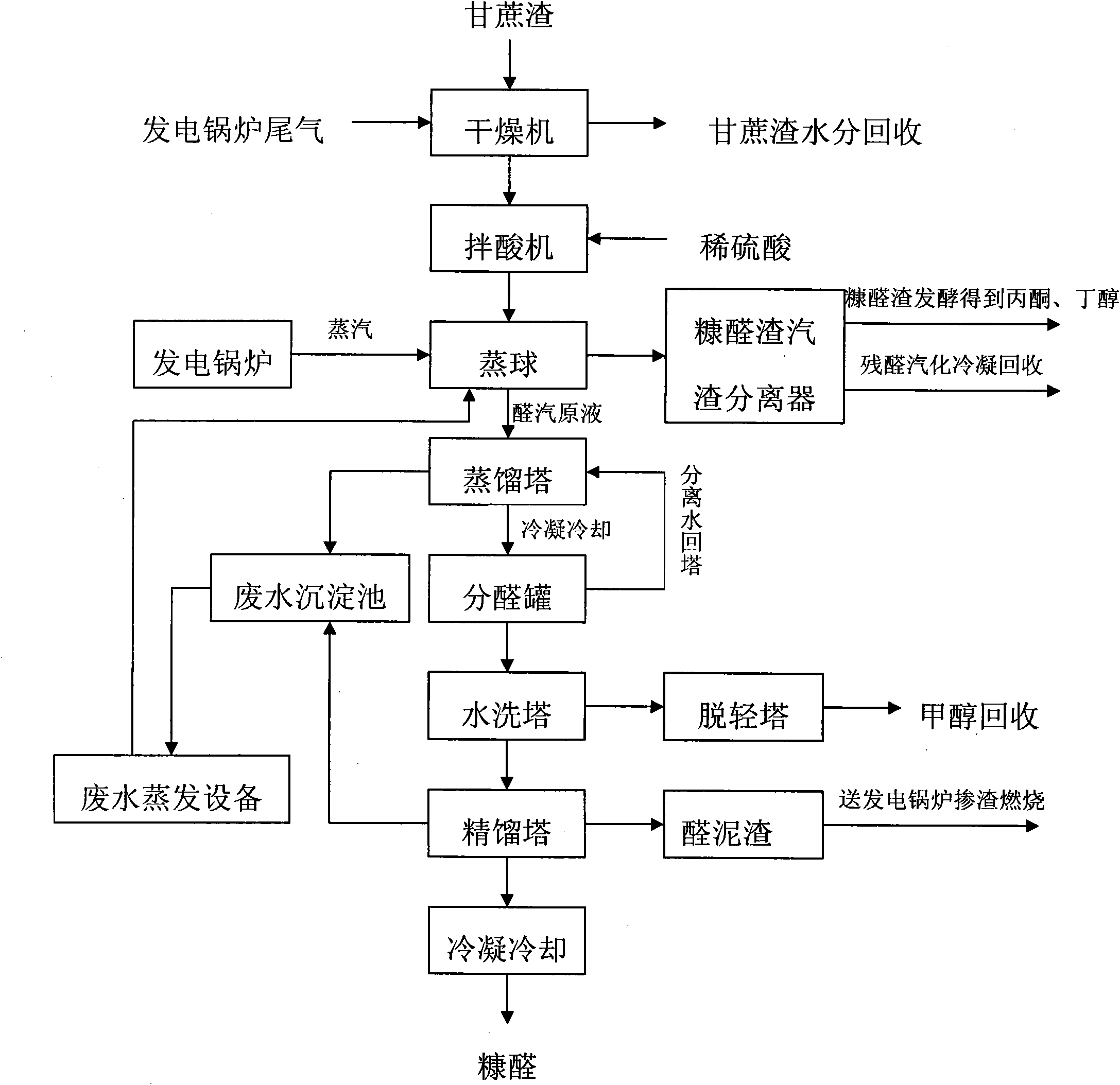

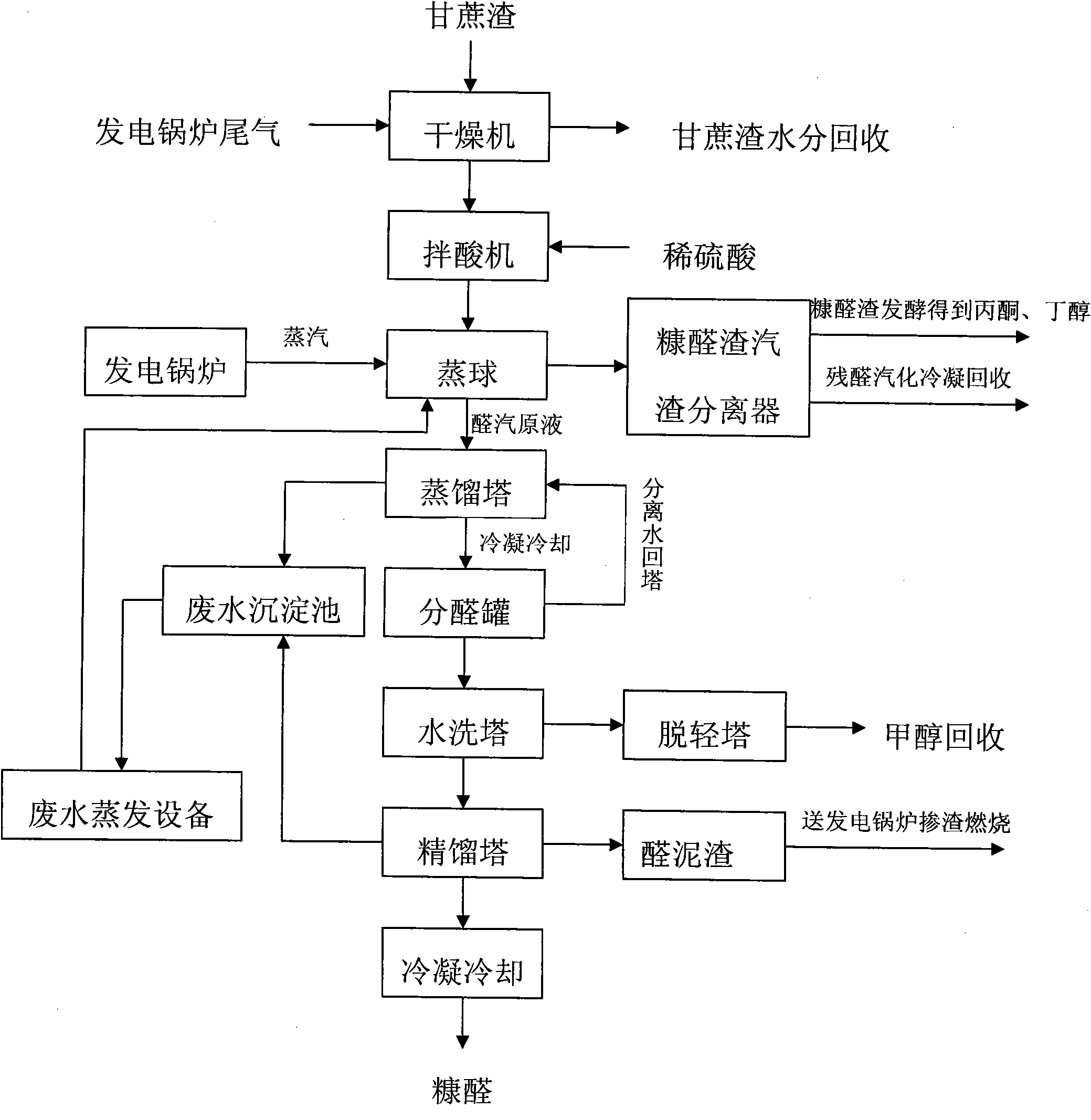

[0024] (1) Bagasse with a water content of 50% (wt / wt) in the sugar industry is sent to a dryer (using the tail gas of a power generation boiler as a heat source to save energy, and the moisture of the bagasse can be recovered simultaneously) for drying to The water content is 30% (wt / wt), then add the dilute sulfuric acid with a concentration of 0.5% (wt / wt) in the bagasse after drying, stir and mix evenly with an acid mixing machine; then the sugarcane after acid mixing slag into the figure 1 The steamed ball shown is hydrolyzed at a steam pressure of 1-1.2Mpa and a steam temperature of 180-190°C for 2 hours (steam is provided by a power boiler, and 16-17 tons of steam is generally used per ton of bagasse) to form an aldehyde vapor stock solution; The mass ratio of bagasse and concentration of 0.5% (wt / wt) dilute sulfuric acid is 1: 0.4;

[0025] (2) Send the aldehyde vapor stock solution obtained in step (1) into the primary distillation tower to steam out most of the wate...

Embodiment 3

[0029](1) Bagasse with a water content of 48% (wt / wt) in the sugar industry is sent to a dryer (utilizing the tail gas of a power generation boiler as a heat source to save energy, and the moisture of the bagasse can be recovered simultaneously) and dried to The water content is 29% (wt / wt), then add the dilute sulfuric acid that concentration is 0.6% (wt / wt) in the dried sugarcane bagasse, stir and mix evenly with the acid mixing machine; Then the sugarcane after the acid mixing slag into the figure 1 The steamed ball shown is hydrolyzed at a steam pressure of 1-1.2Mpa and a steam temperature of 180-190°C for 2 hours (steam is provided by a power boiler, and 16-17 tons of steam is generally used per ton of bagasse) to form an aldehyde vapor stock solution; The mass ratio of bagasse and concentration of 0.6% (wt / wt) dilute sulfuric acid is 1: 0.4;

[0030] (2) Send the aldehyde vapor stock solution obtained in step (1) into the primary distillation tower to steam out most of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com