Preparation method of dispersible silane functionalized graphene

A graphene and dispersibility technology, applied in the field of preparation of dispersible silane-functionalized graphene, can solve the problems of non-amino silane coupling agent silane research, unsatisfactory dispersion effect, graphene agglomeration, etc. Low requirements, few layers, mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

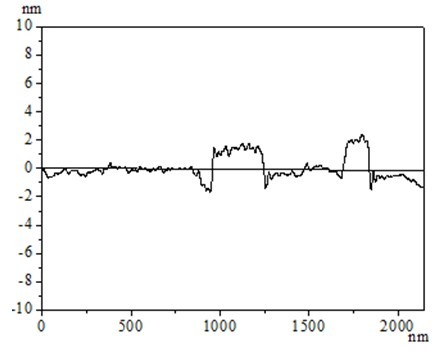

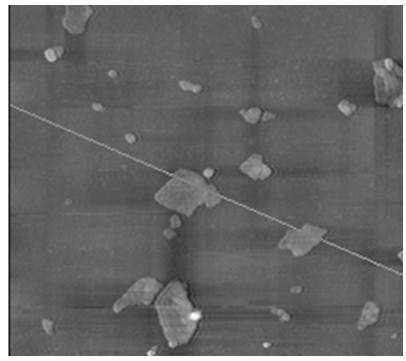

Image

Examples

Embodiment 1

[0022] Preparation of trimethylmethoxysilane functionalized graphene:

[0023] Step 1: Dissolve 100mg of graphite oxide in 100ml of absolute ethanol, ultrasonically disperse for 1 hour to form a uniform dispersion of 1mg / ml, adjust the pH of the dispersion to 3 with dilute hydrochloric acid; The silane mass ratio is 1:0.5, add trimethylmethoxysilane, react at 60°C for 24 hours, centrifuge, remove the supernatant, and wash the subnatant with absolute ethanol and deionized water several times to completely remove Unreacted trimethylmethoxysilane until the washing solution is neutral to obtain silane-modified graphene oxide.

[0024] Step 2: Disperse the above-mentioned silane-modified graphene oxide in 100ml of absolute ethanol and sonicate for 1 hour to become a uniform and stable modified graphene oxide dispersion, then add 1g of hydrazine hydrate and reduce it at 60°C for 48 hours, Then the reaction solution was suction filtered, and the resulting filter cake was washed with...

Embodiment 2

[0028] Triethylmethoxysilane, phenyldimethylmethoxysilane, diphenylmethylmethoxysilane, vinyldimethylmethoxysilane, trimethylethoxysilane, triethylethyl Oxysilane, phenyldimethylethoxysilane, diphenylmethylethoxysilane, vinyldimethylethoxysilane instead of trimethylmethoxysilane, the rest are the same as in Example 1.

Embodiment 3

[0030] Preparation of trimethylchlorosilane functionalized graphene:

[0031] Step 1: Dissolve 100mg of graphite oxide in 10ml of absolute ethanol, and ultrasonically disperse for 1 hour to form a uniform dispersion of 1mg / ml; then under the protection of nitrogen atmosphere, the mass ratio of graphene oxide and trimethylchlorosilane is 1:1 Add trimethylchlorosilane at the ratio of 60 ° C for 24 hours, centrifuge, remove the supernatant, and then wash with absolute ethanol and deionized water several times to completely remove unreacted trimethylchlorosilane, and make the washing Liquid to neutral, obtain silane-modified graphene oxide;

[0032]Step 2: Disperse the above-mentioned silane-modified graphene oxide in 100ml of absolute ethanol and sonicate it for 1 hour to become a uniform and stable modified graphene oxide dispersion, then add 1g of hydrazine hydrate and reduce it at 60°C for 24 hours, Then the reaction solution was suction filtered, and the obtained filter cake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com