Curable composition containing a reactive (meth)acrylate polymer and a cured product thereof

A curable composition, acrylate technology, applied in the directions of graft polymer adhesives, non-polymer organic compound adhesives, ester copolymer adhesives, etc., can solve the loss of surface smoothness and heat resistance Insufficient, lack of flexibility, etc., to achieve the effect of excellent surface hardness and good flexibility

Inactive Publication Date: 2011-04-27

RESONAC HOLDINGS CORPORATION

View PDF4 Cites 27 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when inorganic fillers are added to the resin, its transparency is significantly damaged, the surface smoothness is lost, and the dispersibility is poor, so there is unevenness in the substrate, and there are problems such as easy cracking.

In addition, when an inorganic film is laminated, there are problems such as peeling and cracking due to poor adhesion to resin and large difference in shrinkage.

JP-A-10-298252 (Patent Document 4) describes that colloidal silica is uniformly dispersed in a radically polymerizable vinyl compound such as methyl methacrylate using a silane compound, which is excellent in transparency and rigidity. Curable compositions, but these compositions are mainly designed for hard coating, lack of flexibility, do not have both hardness and flexibility

Moreover, heat resistance is not sufficient

JP-A-09-157315 (Patent Document 5) describes a urethane acrylic monomer containing a (meth)acryloyloxy group in one molecule, having a hydroxyl group, a cyclic ether bond, and a chain ether bond. An ultraviolet curable resin raw material composition of an acrylic monomer and colloidal silica, but in the composition, the colloidal silica is in the state of being dispersed in the urethane (meth)acrylate, and the glue There is no chemical bond between state silica and urethane (meth)acrylate, so the required high elasticity and high heat resistance cannot be obtained

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

manufacture example 1

manufacture example 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| double bond equivalent | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

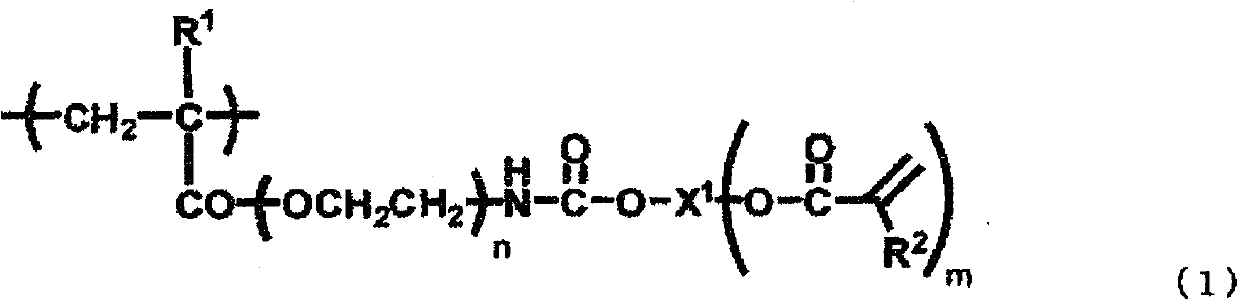

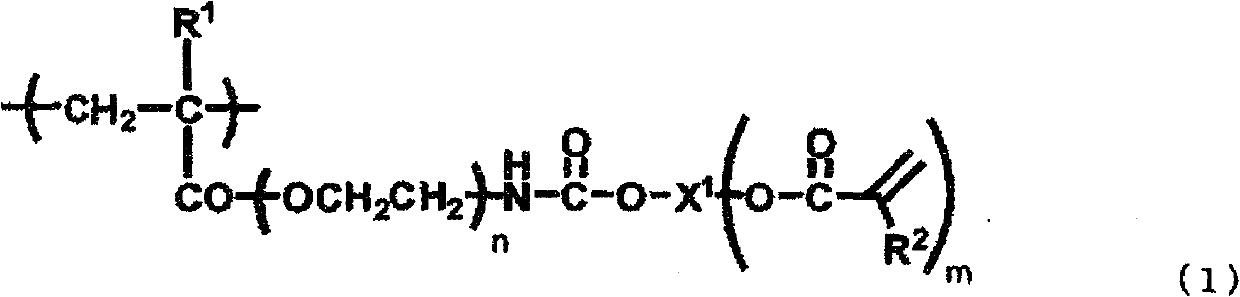

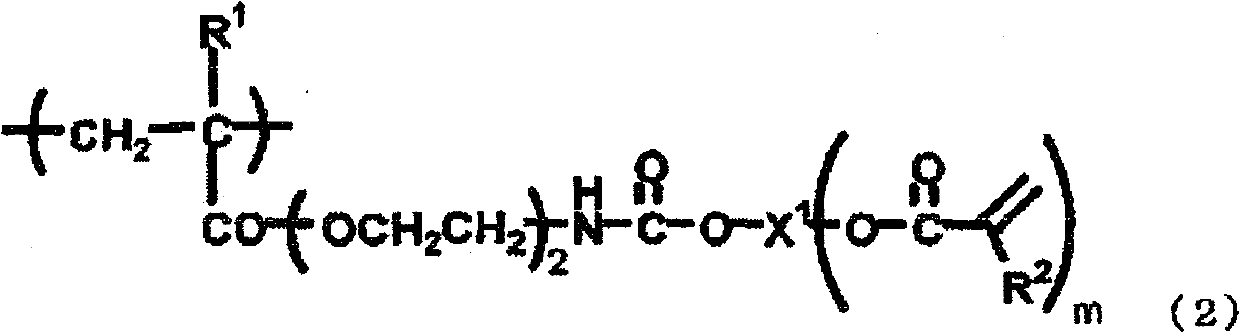

Provided is a curable composition which has superior surface hardness, excellent flexibility and bending properties, and makes it possible to form a heat-resistant cured film having both strength and flexibility, and a cured product (film) thereof. The curable composition includes a reactive (meth)acrylate polymer (A) having the monomer unit indicated by general formula (1), a polymerization initiator (B), and a reactive monomer (C). In formula (1), R1 represents a hydrogen atom, a methyl group, or an ethyl group; R2 represents a hydrogen atom or a methyl group; X1 represents a straight chain or branched hydrocarbon group of 2 - 6 carbon atoms, or polyethylene glycol, polypropylene glycol, or an alcohol residue of a caprolactone-modified terminal diol on both ends; and n represents an integer from 2 to 4, and m represents an integer from 1 to 5.

Description

technical field The present invention relates to a curable composition cured by irradiation or heating of active energy rays such as ultraviolet rays and electron beams, and a cured product thereof. More specifically, the present invention relates to a curable composition capable of forming a cured product excellent in hardness, scratch resistance, heat resistance and flexibility, and a cured product thereof. Background technique In recent years, it has been used in protective coating materials used to prevent scratches and contamination on the surface of various substrates, adhesives for various substrates, ceiling materials, film-type liquid crystal elements, touch panels, and anti-reflection of plastic optical components. For film applications, a curable composition capable of forming a cured film excellent in hardness, flexibility, scratch resistance, abrasion resistance, low curling property, high refractive index, adhesion and transparency is required. Among these req...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F290/12C08F8/00C08G18/67C09D4/00C09D133/00C09D151/08C09D175/14C09J4/00C09J133/00C09J151/08C09J175/14

CPCC08L75/04C09J175/14C08G18/6254C08G18/672C09J133/14C08F220/36C09J4/06C08G18/8116C08F2220/343C09D133/14C08G18/6229C08L2666/20C08F220/343C08F220/346

Inventor 大井宽子服部阳太郎石井伸晃室伏克己

Owner RESONAC HOLDINGS CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com