Base Film of Modified Polyvinyl Alcohol and Its Preparation Method and Polarizer

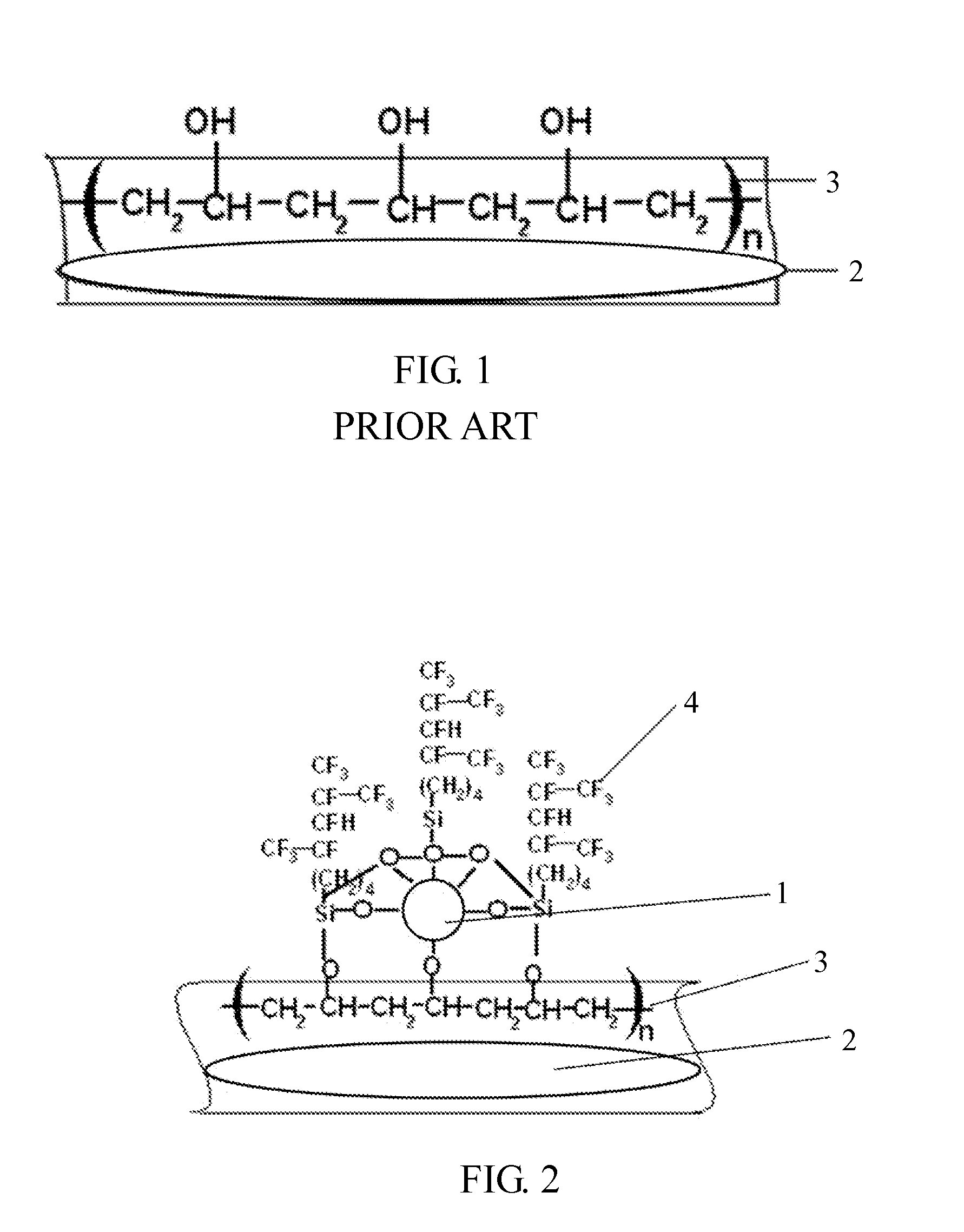

a technology of polyvinyl alcohol and base film, which is applied in the field of base film, can solve the problems of iodine polarizers that are comparatively less resistant to heat and water, difficulty in pva base film modification for development of polarizers with excellent optical and durability performance for lcds, and easy damage to iodine molecular structure, etc., and achieves excellent waterproof characteristics, high light transmission rate, and certain degree of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053]The structure and the technical means adopted by the present invention to achieve the above and other objects can be best understood by referring to the following detailed description of the preferred embodiment and the accompanying drawings, but should not be construed as limitations thereof.

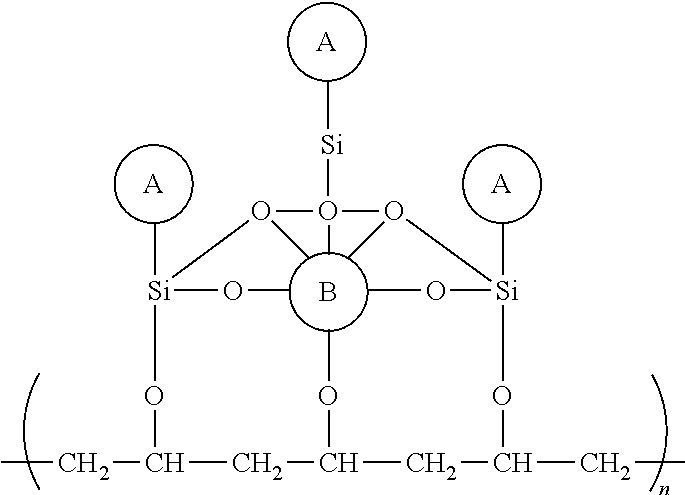

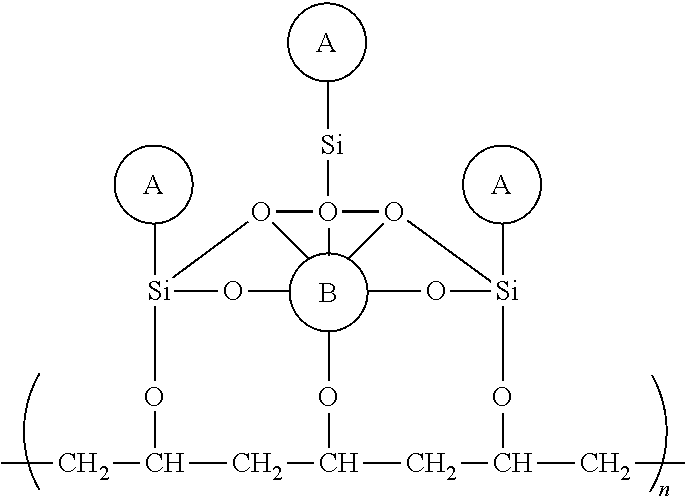

[0054]According to a preferred embodiment of the present invention, the present invention provides a base film of modified polyvinyl alcohol (PVA) and its preparation method, wherein its specific preparation steps include:

[0055](1) Surface graft modification of nano-silicon dioxides using fluorinated silane: 6 g of dried nano-silicon dioxide particles, 120 ml of anhydrous ethanol, 6.5 g of deionized water, 3.4 g of ammonia of 25% weight percentage and 2.0˜2.4 g of dodecafluoro-heptyl-propyl-trimethoxy-silane are added in a round-bottom flask in turn; after 1 hour of ultrasonic dispersion and then stirring in high speed for 5 hours under 40° C., processing with filtration and deposition, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of alcoholysis | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com