Boron-doped diamond electrode and preparation method and application thereof

A boron-doped diamond and diamond layer technology, applied in chemical instruments and methods, metal material coating technology, ion implantation plating, etc., can solve the problems of low electrochemical catalytic activity of BDD electrodes, easy to fall off, poor binding force, etc. , to achieve good electrical conductivity, compact structure, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

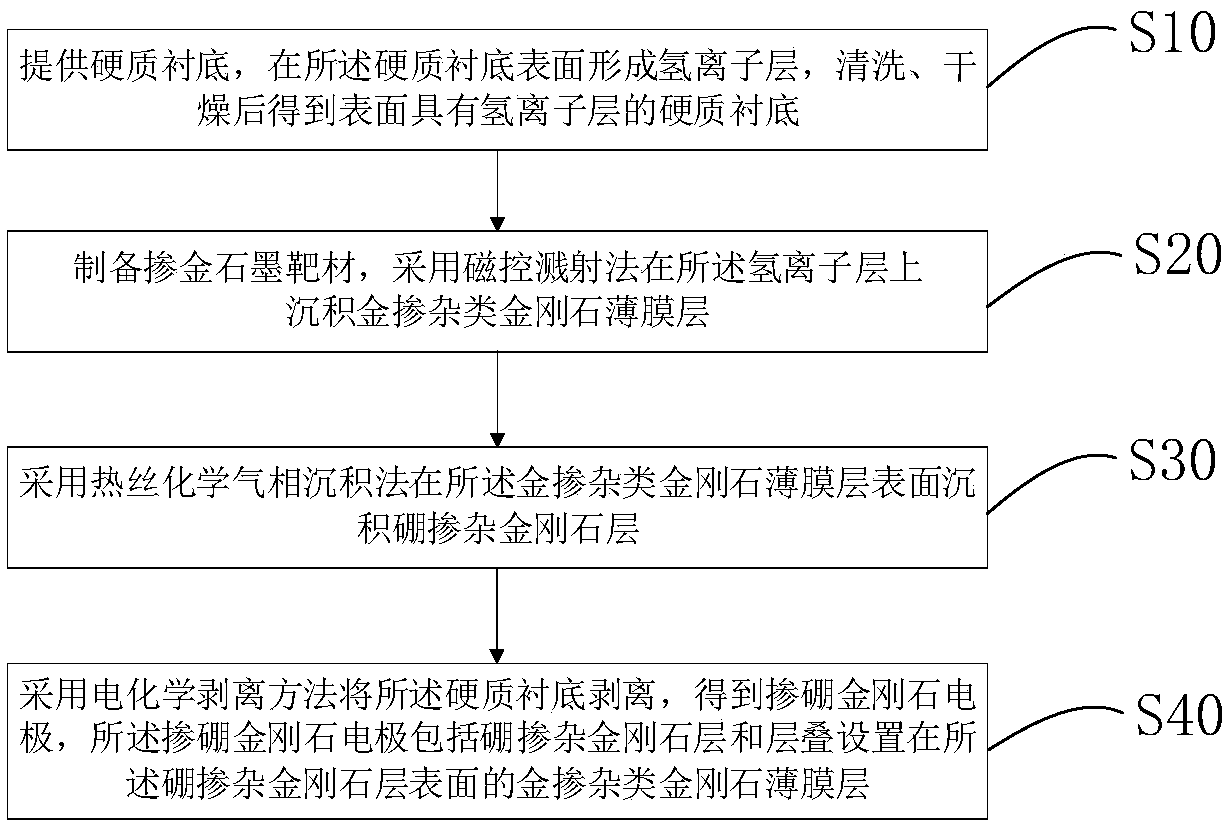

[0050] Such as image 3 As shown, this embodiment also provides a method for preparing a boron-doped diamond electrode, including:

[0051] S10, providing a hard substrate, forming a hydrogen ion layer on the surface of the hard substrate, cleaning and drying to obtain a hard substrate with a hydrogen ion layer on the surface;

[0052] S20, preparing a gold-doped graphite target, and depositing a gold-doped diamond-like carbon film layer on the hydrogen ion layer by magnetron sputtering;

[0053] S30. Depositing a boron-doped diamond layer on the surface of the gold-doped diamond-like carbon film layer by hot wire chemical vapor deposition;

[0054] S40. Using the electrochemical stripping method to peel off the hard substrate to obtain a boron-doped diamond electrode, the boron-doped diamond electrode includes a boron-doped diamond layer and a gold-doped layer stacked on the surface of the boron-doped diamond layer diamond-like film layer.

[0055] In the embodiment of the...

Embodiment 1

[0063] A method for preparing a boron-doped diamond electrode, comprising:

[0064] S110. Take a single crystal silicon wafer substrate, place the single crystal silicon wafer in ethanol and deionized water for 5 minutes, and ultrasonically clean the substrate surface; inject energy perpendicular to the surface of the single crystal silicon wafer substrate to be 100KeV The hydrogen ions form a hydrogen ion layer, the hydrogen ion implantation depth is 2μm, and the hydrogen ion implantation dose is 3×10 16 ions / cm 2 ; Anneal the single crystal silicon wafer substrate implanted with hydrogen ions in an argon atmosphere for 5 minutes at an annealing temperature of 850°C to obtain a single crystal silicon wafer substrate with a hydrogen ion layer on the surface; then use ethanol and deionized water to ultrasonically Wash for 5 minutes to remove oil and dust on the surface, and blow dry with nitrogen for later use.

[0065] S120. After mixing the gold powder and the graphite powd...

Embodiment 2

[0069] A method for preparing a boron-doped diamond electrode, comprising:

[0070] S210. Take a single-crystal silicon wafer substrate, place the single-crystal silicon wafer in ethanol and deionized water for 5 minutes, and ultrasonically clean the substrate surface; inject energy perpendicular to the surface of the single-crystal silicon wafer substrate to be 100KeV. The hydrogen ions form a hydrogen ion layer, the hydrogen ion implantation depth is 3μm, and the hydrogen ion implantation dose is 5×10 16 ions / cm 2 ; Anneal the single crystal silicon wafer substrate implanted with hydrogen ions in an argon atmosphere for 5 minutes at an annealing temperature of 900°C to obtain a single crystal silicon wafer substrate with a hydrogen ion layer on the surface; then use ethanol and deionized water to ultrasonically Wash for 5 minutes, and blow dry with nitrogen for later use.

[0071] S220. After mixing the gold powder and the graphite powder evenly, place them in a steel mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com