Preparation method of building composite waterproof material

A waterproof material and building technology, applied in the field of building materials, can solve problems such as cracking, reducing the service life of buildings, falling off, etc., and achieve the effects of high bonding strength, improved durability, and improved water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

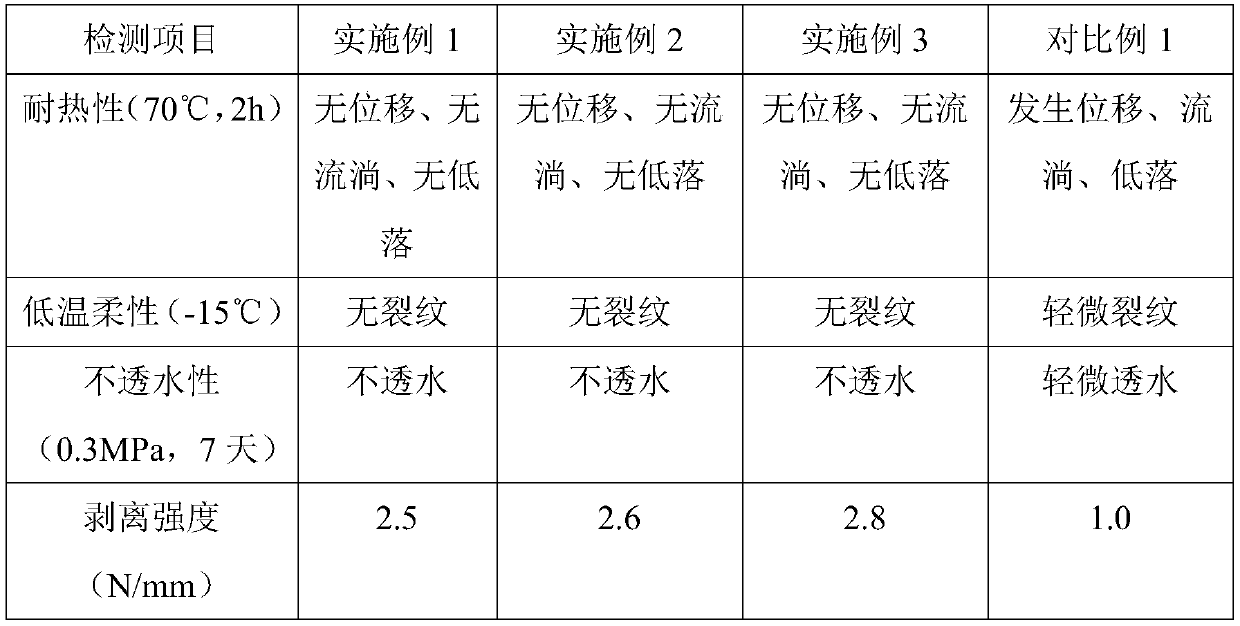

Examples

Embodiment 1

[0034] In parts by weight, weigh 30 parts of acrylic acid, 18 parts of methyl methacrylate, 15 parts of n-butyl acrylate, 15 parts of styrene, 0.6 parts of ammonium persulfate, 3 parts of sodium lauryl sulfate, 6 parts of Sodium bicarbonate, 60 parts of deionized water, adding sodium lauryl sulfate to deionized water, stirring at 160r / min for 10min at room temperature to obtain an emulsifier solution, adding acrylic acid, methyl methacrylate, n-butyl acrylate Add styrene to the emulsifier solution, stir at 240r / min at room temperature for 1 hour to obtain a pre-emulsion, add sodium bicarbonate to the emulsion, and stir at 280r / min for 40min in a water bath at 50°C to obtain a mixed pre-emulsion , add ammonium persulfate to the mixed pre-emulsion, stir at a speed of 320r / min in a water bath at 80°C for 1h, add dropwise 1% ammonia water to adjust the pH to 8, and cool at room temperature to obtain a styrene-acrylic emulsion; In terms of parts, weigh 10 parts of nano-silica, 8 pa...

Embodiment 2

[0036] In parts by weight, weigh 35 parts of acrylic acid, 21 parts of methyl methacrylate, 17 parts of n-butyl acrylate, 17 parts of styrene, 0.7 parts of ammonium persulfate, 3.5 parts of sodium lauryl sulfate, 7 parts of Sodium bicarbonate, 70 parts of deionized water, sodium lauryl sulfate was added into the deionized water, stirred at a speed of 170r / min for 13min at room temperature to obtain an emulsifier solution, and acrylic acid, methyl methacrylate, n-butyl acrylate , Styrene was added to the emulsifier solution, stirred at 260r / min at normal temperature for 1.5h to obtain a pre-emulsion, sodium bicarbonate was added to the emulsion, and stirred at 290r / min for 50min in a water bath at 55°C to obtain a mixed pre-emulsion For the emulsion, ammonium persulfate was added to the mixed pre-emulsion, stirred at a speed of 340 r / min in a water bath at 85°C for 1.5 h, and 1% ammonia water was added dropwise to adjust the pH to 8.5, cooled at room temperature to obtain a styr...

Embodiment 3

[0038] In parts by weight, weigh 40 parts of acrylic acid, 24 parts of methyl methacrylate, 20 parts of n-butyl acrylate, 20 parts of styrene, 0.8 parts of ammonium persulfate, 4 parts of sodium lauryl sulfate, 8 parts of Sodium bicarbonate, 80 parts of deionized water, adding sodium lauryl sulfate to deionized water, stirring at 180r / min for 15min at room temperature to obtain an emulsifier solution, adding acrylic acid, methyl methacrylate, n-butyl acrylate Add styrene to the emulsifier solution, stir at 280r / min at room temperature for 2h to obtain a pre-emulsion, add sodium bicarbonate to the emulsion, and stir at 300r / min for 60min in a water bath at 60°C to obtain a mixed pre-emulsion , add ammonium persulfate to the mixed pre-emulsion, stir at 360r / min for 2h in a water bath at 90°C, add dropwise 1% ammonia water to adjust the pH to 9, and cool at room temperature to obtain a styrene-acrylic emulsion; In terms of parts, weigh 20 parts of nano-silica, 16 parts of methylt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com