Thin-wall high-temperature-resistant radiation-resistant flame-retardant cable material polyether-ether-ketone and preparation method thereof

A flame retardant cable material, polyether ether ketone technology, applied in the field of polyether ether ketone, can solve the problems of material mechanical properties decline, affecting flame retardant performance, etc., to achieve the effect of good stability and lasting flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

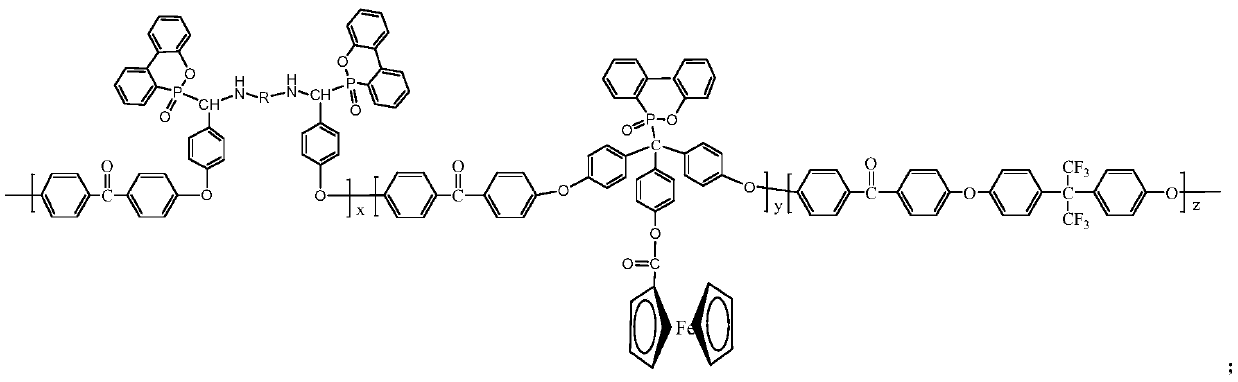

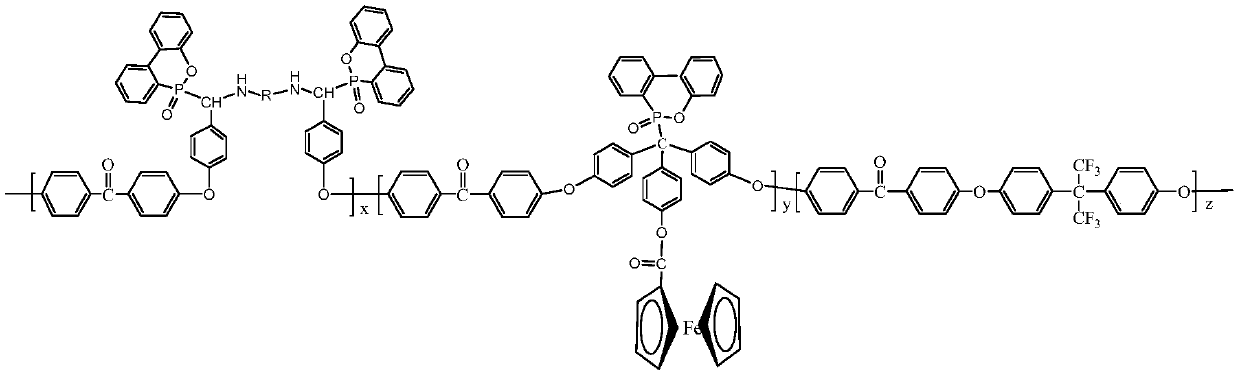

[0028] (1)) Preparation of bisphenol monomers containing ferrocene and DOPO groups: 2.9041 g of DOPO-based trihydric phenols, 2.3004 g of ferrocenecarboxylic acid, 2.4534 g of 4-dimethylaminopyridine and di Chloromethane 120mL, put it in an ice bath, stir and fill with N2 gas, after 30min, dissolve 2.0830g N,N'-dicyclohexylcarboimide in 10mL dichloromethane, add the above solution dropwise within 60min In the process, the temperature was naturally raised to room temperature under stirring and the reaction was continued for 24 hours. The reaction solution was concentrated, cooled, filtered, washed and dried, and the precipitate was dried in a vacuum oven at 40°C for 10 hours to obtain a bisphenol monomer containing ferrocene and DOPO groups. .

[0029]

[0030] (2) Preparation of DOPO substituent bisphenol monomer (I): Add 6.1060g of p-hydroxybenzaldehyde, 4.9565g of 4,4'-diaminodiphenylmethane and 90mL of ethyl acetate in a single-necked bottle, stir well, and nitrogen Rea...

Embodiment 2

[0035] (1) Preparation of ferrocene and DOPO-based bisphenol monomers: Add 2.9041 g of DOPO-based trihydric phenol, 2.0326 g of triethylamine, and 120 mL of dichloromethane in a three-necked flask, and place it in an ice bath After stirring for 30 minutes, dissolve 2.4754 g of ferrocenecarbonyl chloride in dichloromethane and drop into the above solution, naturally warm to room temperature under stirring and continue to react for 24 hours, concentrate the reaction solution, cool, filter, wash and dry, and place the precipitate Dry in a vacuum oven at 40°C for 5 hours to obtain a bisphenol monomer containing ferrocene and DOPO groups.

[0036](2) Preparation of bisphenol monomer (II) containing DOPO substituent: add 6.1060g of p-hydroxybenzaldehyde, 2.7035g of p-phenylenediamine and 90mL of absolute ethanol in a one-mouth bottle, stir evenly, and place in a nitrogen atmosphere at 40°C React for 2h, then add 10.8085gDOPO to continue the reaction for 24h, and terminate the reacti...

Embodiment 3

[0041] (1) Preparation of ferrocene and DOPO-based bisphenol monomers: Add 2.9041 g of DOPO-based trihydric phenol, 2.0326 g of triethylamine and 120 mL of dichloromethane in a three-necked flask, and put it in an ice bath After stirring for 30 minutes, dissolve 2.4754 g of ferrocenecarbonyl chloride in dichloromethane and drop into the above solution, naturally warm to room temperature under stirring and continue to react for 24 hours, concentrate the reaction solution, cool, filter, wash and dry, and place the precipitate Dry in a vacuum oven at 40°C for 5 hours to obtain a bisphenol monomer containing ferrocene and DOPO groups.

[0042] (2) Preparation of bisphenol monomer (Ⅲ) containing DOPO substituent: add 6.1060g of p-hydroxybenzaldehyde, 5.0060g of 4,4'-diaminodiphenyl ether and 100mL of ethyl acetate into a one-mouth bottle, stir well, and nitrogen React at 50°C for 2 hours in the atmosphere, then add 10.8085g DOPO to continue the reaction for 24 hours, and terminate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com