Method for preparing lithium battery polymer electrolyte having high conductivity

A high-conductivity, polymer technology, applied in the manufacture of electrolyte batteries, solid electrolytes, non-aqueous electrolytes, etc., can solve problems such as low conductivity and inability to meet the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

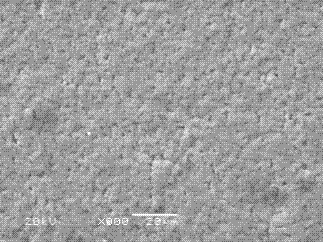

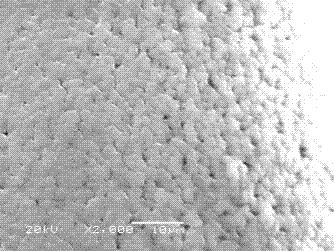

Image

Examples

specific Embodiment approach 1

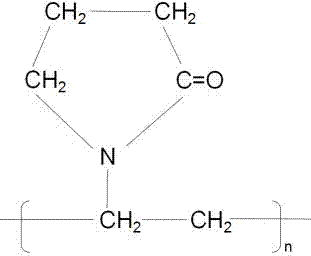

[0022] Embodiment 1: A method for preparing a high-conductivity solid polymer electrolyte based on polyvinylidene fluoride (PVDF), which is characterized in that it is carried out according to the following steps:

[0023] Step 1: Put PVDF, polyvinylpyrrolidone (PVP), and ethylenediaminetetraacetic acid (EDTA) in a dry box for processing.

[0024] Step 2: Dissolve 0.5g of PVDF in 3.5mL of N,N-methylformamide (DMF) solvent, stir for 12 hours, weigh 0.85g of EDTA and disperse in 1mL of DMF solvent, stir for 12 hours, mix the two Stirring was continued for another 12 hours.

[0025] Step 3: Weigh 0.01g of PVP and disperse in 1mL DMF solvent for 3 hours, and continue mixing with the solution mixed with PVDF and EDTA.

[0026] Step 4: Add 0.25 g of lithium bistrifluoromethanesulfonimide to the mixture, and continue stirring for 6 hours until the polymer is stable and uniform.

[0027] Step 5: Adhere the scotch tape on a clean glass plate in parallel lines, control the thickness b...

specific Embodiment approach 2

[0032] Specific embodiment 2: This embodiment is a further description of the method of specific embodiment 1 using polyvinylidene fluoride (PVDF) as the matrix solid polymer electrolyte. The second step is: dissolving 0.5g of PVDF in 3.5mL Stir in N,N-methylformamide (DMF) solvent for 12 hours, weigh 0.85 g of EDTA and disperse in 1 mL of DMF solvent, stir for 12 hours, mix the two and then stir for 12 hours.

specific Embodiment approach 3

[0033] Specific embodiment three: This embodiment is a further description of the method of the solid polymer electrolyte based on polyvinylidene fluoride (PVDF) in the specific embodiment one. The third step is: weigh 0.01g of PVP and disperse it in 1mL DMF Solvent for 3 hours, continued mixing with solution mixed with PVDF and EDTA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com