Method for preparing formaldehyde room temperature oxidation catalyst

An oxidation catalyst, room temperature technology, used in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of complex process, large particle size, poor dispersion, etc., and achieve low preparation cost and high activity. , the effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of Formaldehyde Oxidation Catalyst at Room Temperature

[0025] (1) The carrier TiO 2 Disperse in water under the action of stirring, and then add chloroplatinic acid solution, where the added platinum is relative to TiO 2 The mass content of is 1wt%, continues to stir 1 hour;

[0026] (2) Add a mixture of 0.1 mol / L sodium borohydride and 0.5 mol / L sodium hydroxide to the solution in step (1) to reduce the precious metals to metal nanoparticles, sodium hydroxide, sodium borohydride and platinum The mol ratio is 25:5:1, and the pH value is between 9~10, continues to stir for 20 minutes;

[0027] (3) Heat, stir and evaporate the precious metal-deposited carrier obtained in step (2), the evaporation is carried out at 100°C, and the evaporation time is within 4 hours;

[0028] (4) The product obtained in step (3) was dried at 80°C for 12 hours, cooled and ground to obtain a formaldehyde room temperature oxidation catalyst.

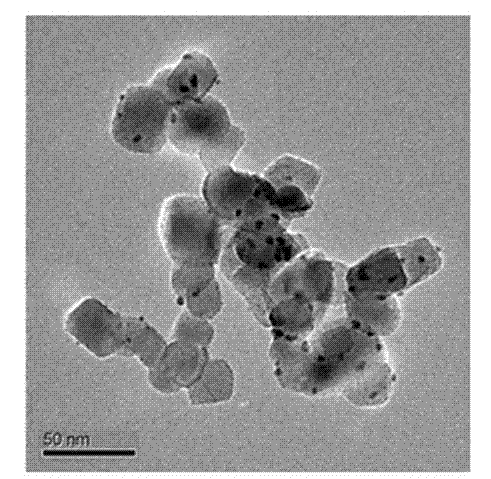

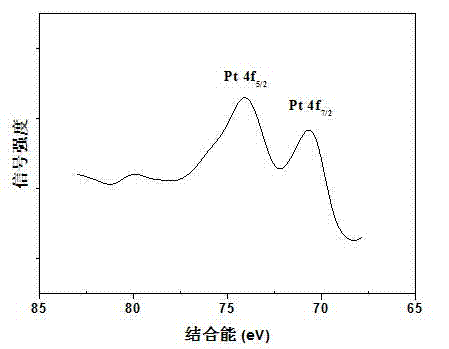

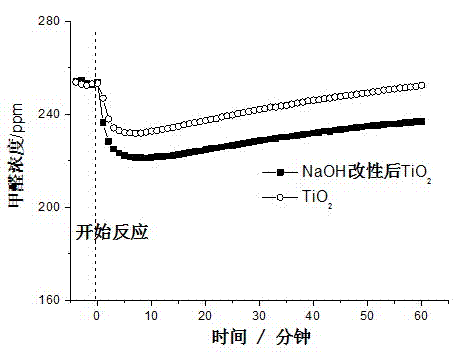

[0029] The FETEM and XPS spectrog...

Embodiment 2

[0031] Preparation of Formaldehyde Oxidation Catalyst at Room Temperature

[0032] (1) The carrier TiO 2Disperse in water under the action of stirring, and then add chloroplatinic acid solution, where the added platinum is relative to TiO 2 The content of is 1 wt %, continue stirring for 1 hour;

[0033] (2) Add 0.1 mol / L sodium borohydride solution to the solution in step (1) to reduce the noble metal to metal nanoparticles. The molar ratio of sodium borohydride and platinum is 5:1, and the pH value is between 9 and 10. Between, continue stirring for 20 minutes;

[0034] (3) Heat, stir and evaporate the precious metal-deposited carrier obtained in step (2), the evaporation is carried out at 100°C, and the evaporation time is within 4 hours;

[0035] (4) The product obtained in step (3) was dried at 80°C for 12 hours, cooled and ground to obtain a formaldehyde room temperature oxidation catalyst.

Embodiment 3

[0037] Preparation of Formaldehyde Oxidation Catalyst at Room Temperature

[0038] (1) The carrier TiO 2 Disperse in water under the action of stirring, and then add chloroplatinic acid solution, where the added platinum is relative to TiO 2 The content of is 0.5wt%, continues to stir 1 hour;

[0039] (2) Add a mixture of 0.1 mol / L sodium borohydride and 0.5 mol / L sodium hydroxide to the solution in step (1) to reduce the precious metals to metal nanoparticles, sodium hydroxide, sodium borohydride and platinum The mol ratio is 25:5:1, and the pH value is between 9~10, continues to stir for 20 minutes;

[0040] (3) Heat, stir and evaporate the precious metal-deposited carrier obtained in step (2), the evaporation is carried out at 100°C, and the evaporation time is within 4 hours;

[0041] (4) The product obtained in step (3) was dried at 80°C for 12 hours, cooled and ground to obtain a formaldehyde room temperature oxidation catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com