Three-dimensional porous current collector as well as preparation method and use thereof

A three-dimensional porous and current collector technology, applied in the field of electrochemical power sources, can solve the problems of poor mechanical strength of porous copper, low purity of porous copper, unsuitable current collectors, etc., and achieve the goal of suitable for large-scale production and suppressing dendrite The effect of formation and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of three-dimensional porous copper foil

[0025] (1) Wash the copper foil (purchased from Great Britain Cambridge Co., Ltd., about 25 μm) with dilute hydrochloric acid and distilled water, then sink into the bottom of ammonia water (5wt%) to soak, and let it stand for 36 hours;

[0026] (2) Remove Cu(OH) deposited on the surface 2 For the copper foil that turns blue, wash the residual ammonia water on the surface with water, and then dry it in an oven at 60°C;

[0027] (3) Place the dried copper foil in a muffle furnace at 5°C min -1 The heating rate is heated to 180°C and maintained for 4h, the Cu(OH) 2 Dehydration forms CuO.

[0028] (4) Put the copper foil in a tube furnace, and heat it at 5°C for min in a hydrogen-argon mixed atmosphere (hydrogen 5% volume ratio). -1 The heating rate was heated to 400 °C and maintained for 10 h to reduce CuO to copper. The obtained copper foil is a three-dimensional porous copper foil.

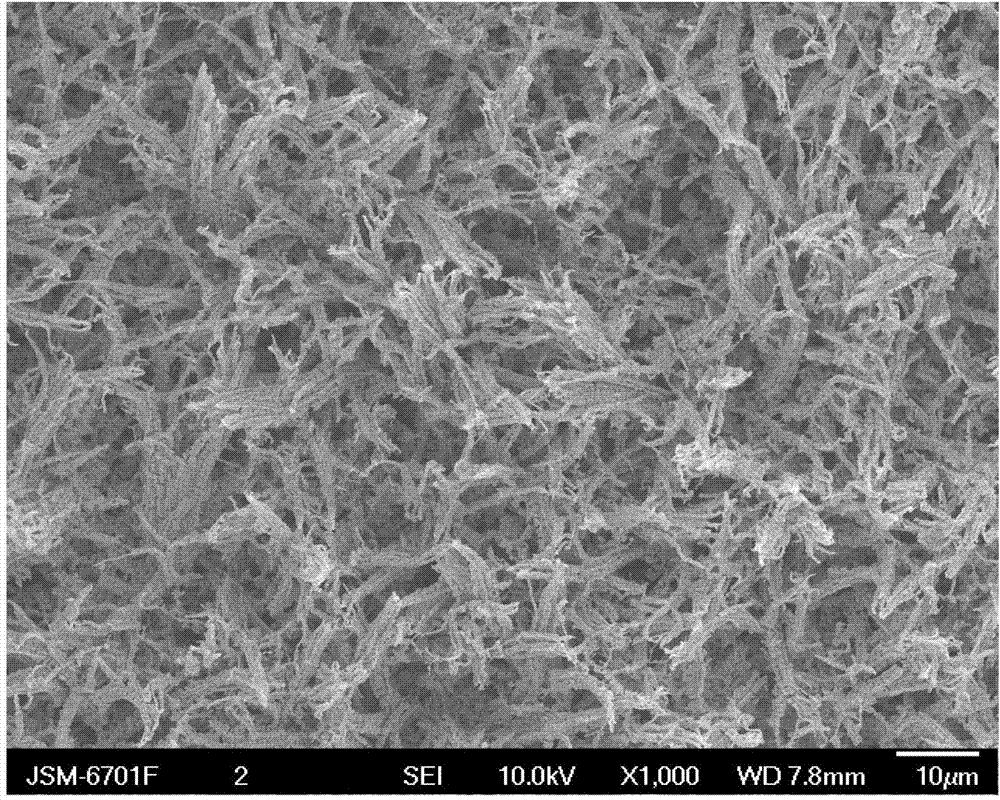

[0029] From figure 1 T...

Embodiment 2

[0039] The only difference from Example 1 is that (1) to prepare three-dimensional porous copper foil, the concentration of ammonia water used is 1 wt%.

[0040] After testing, the obtained three-dimensional porous copper structure is composed of micron bundles, each micron bundle is composed of micron fibers, the diameter of the micron fibers is about 1 μm, the thickness of the porous structure is about 10 μm, the pore diameter is 5-10 μm, and the pore volume is 1×10 -3 cm 3 / cm 2 .

[0041] The three-dimensional porous copper foil prepared above is used as the cathode, and the lithium sheet is used as the anode. After electrolysis, lithium is deposited in the pores of the copper to obtain the lithium metal negative electrode. It can be clearly seen that the lithium metal negative electrode is deposited along the three-dimensional copper skeleton and filled Copper-filled pores without vertical growth of lithium dendrites.

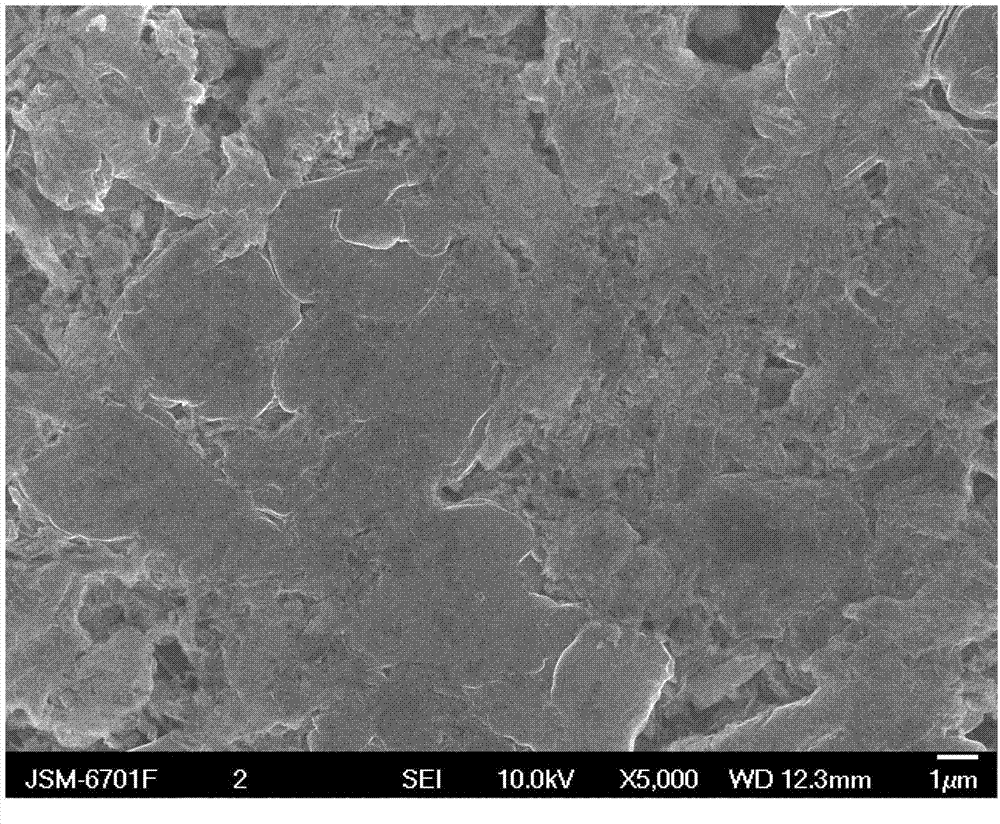

[0042] According to the scanning electron microsc...

Embodiment 3

[0044] The only difference from Example 1 is that (1) to prepare three-dimensional porous copper foil, the concentration of ammonia water used is 10wt%.

[0045] After testing, the obtained three-dimensional porous copper structure is composed of micron bundles, each micron bundle is composed of micron fibers, the diameter of the micron fibers is 1.5-2 μm, the thickness of the porous structure is about 50 μm, the pore diameter is 10-20 μm, and the pore volume is 5× 10 -3 cm 3 / cm 2 .

[0046] The three-dimensional porous copper foil prepared above is used as the cathode, and the lithium sheet is used as the anode. After electrolysis, lithium is deposited in the pores of the copper to obtain the lithium metal negative electrode. It can be clearly seen that the lithium metal negative electrode is deposited along the three-dimensional copper skeleton and filled Copper-filled pores without vertical growth of lithium dendrites.

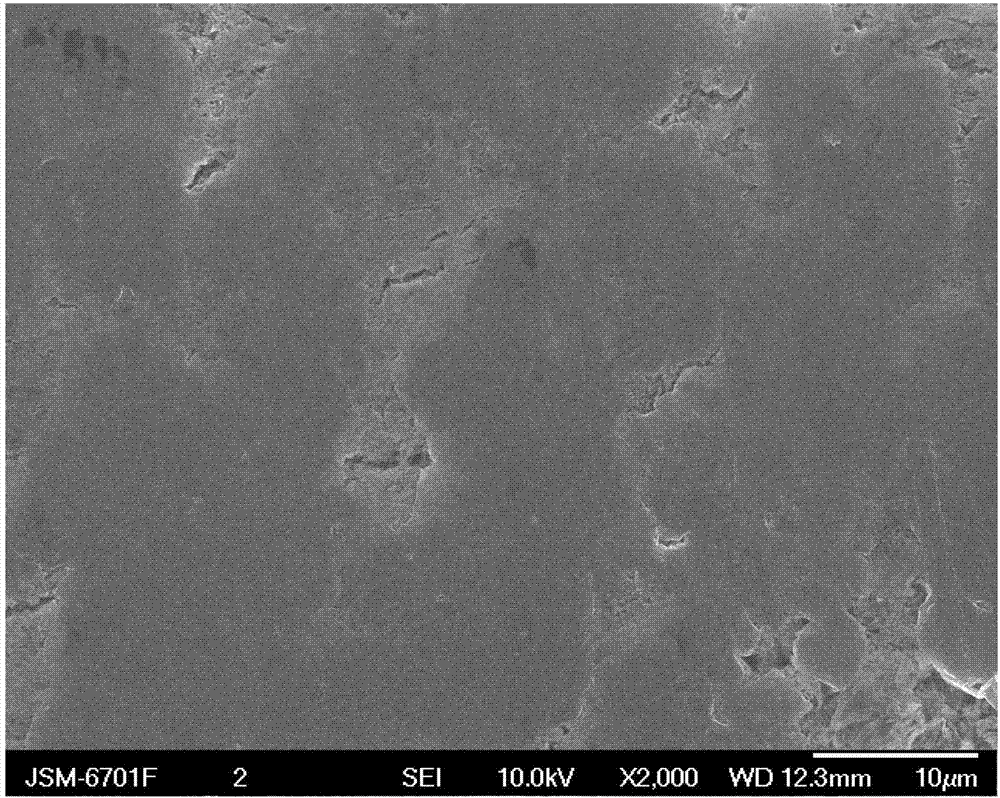

[0047] According to the scanning electron micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com