Silicon-carbon composite anode material and preparing method thereof

A negative electrode material and silicon-carbon composite technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as difficult charging and discharging, and the inability to fully utilize the maximum capacity of silicon materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

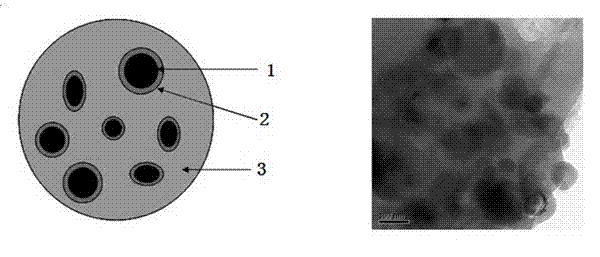

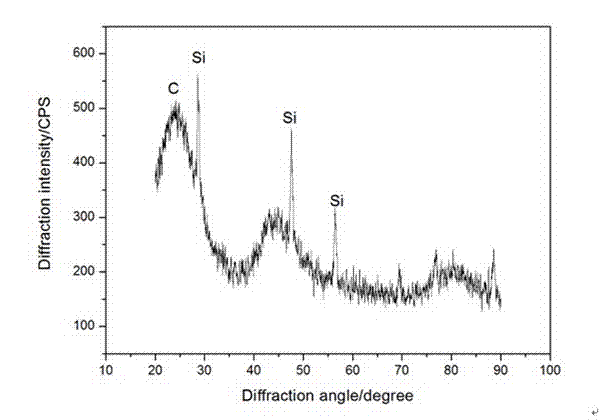

[0030] This embodiment is an embodiment of a silicon-carbon composite negative electrode material.

[0031] The silicon-carbon composite negative electrode material provided in this embodiment is realized through the following steps:

[0032] The first step is to select a biomass material, wash and dry it, then heat-treat it under vacuum or inert atmosphere conditions, and use chemical activation to expand pores to prepare porous carbon. Specifically, wash and dry the leaves of Zizania ziba 2 Down 650 o After C heat treatment, according to K 2 CO 3 : Zizania leaves after heat treatment = 1:0.1 weight ratio to prepare an aqueous solution and soak for 5 hours, filter and dry, at 1000 o Activation by heat treatment at C for 1 hour, removing excess active agent with 9% dilute hydrochloric acid, washing with water to obtain porous carbon, pulverizing and sieving to a size of 10 microns as a support matrix;

[0033] In the second step, the silicon powder and the porous carbon o...

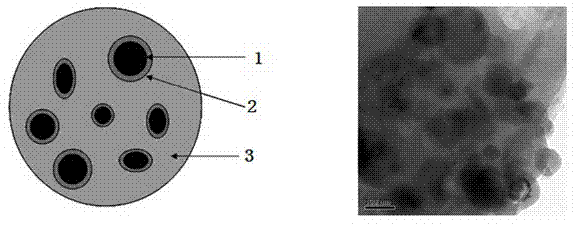

Embodiment 2

[0037]This example is a modification example of the preparation method of the silicon-carbon composite negative electrode material in Example 1. The difference is that in the first step, the biomass material is hydrolyzed to prepare small molecule organic matter, and then it is combined with the Silicon compound.

[0038] The silicon-carbon composite negative electrode material that embodiment 2 provides is realized through the following steps:

[0039] The first step is to select biomass materials, wash and dry them, and then hydrolyze them at a certain temperature to obtain small molecular organic matter, which is the precursor of the porous carbon support matrix. Specifically, wash and dry 5g of Zizania japonica leaves, crush them into 5mm particles, add them into 5wt% dilute nitric acid solution, put them in a water bath at 60°C under stirring until the hydrolysis is complete, and evaporate the solution to obtain a small molecular organic compound. The small molecular orga...

Embodiment 3

[0044] This example is a modification example of the preparation method of the silicon-carbon composite negative electrode material in Example 1, the difference is that wood powder is selected as the biomass material.

[0045] The silicon-carbon composite negative electrode material that embodiment 3 provides is realized through the following steps:

[0046] The first step is to select a biomass material, wash and dry it, heat-treat it under vacuum or an inert atmosphere, and use chemical activation to expand the pores of the biomass material to prepare porous carbon. Specifically, the wood powder is washed and dried, and the wood powder is washed and dried in N 2 Down 650 o After C heat treatment, configure the aqueous solution according to the weight ratio of KOH: wood flour after heat treatment = 1:5 and soak for 5 hours, filter and dry, at 300 o Activation by heat treatment for 12 hours at C, remove excess active agent with 9% dilute hydrochloric acid, and obtain porous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com