Covering material for immobilized in-situ remediation of nitrogen in bottom sediment and preparation method thereof

A covering material and in-situ repairing technology, which is applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of poor biocompatibility and low strength, and achieve low cost and low bioburden The effect of good performance and strong ion exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

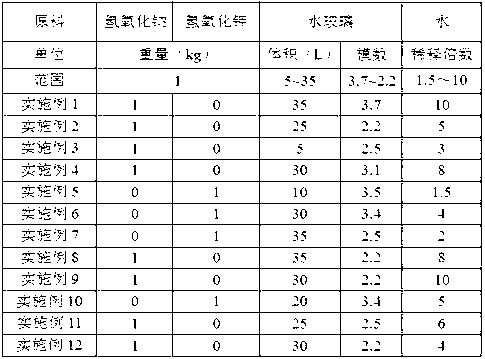

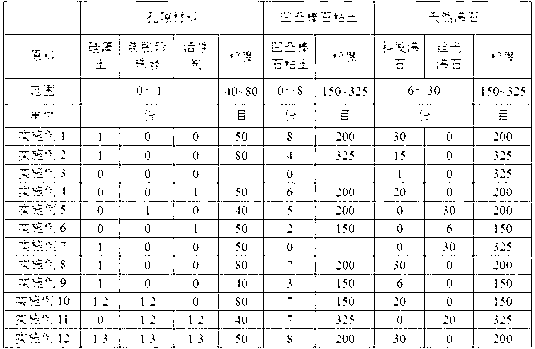

Embodiment 1

[0038] 1 part (by kilogram) of 50 mesh diatomite powder plus 8 parts (by kilogram) of 200 mesh attapulgite clay powder and 30 parts (by kilogram) of 200 mesh clinoptilolite powder, fully mixed in a mixer to prepare The powder raw material is ready for use. Add 1 part (in kilograms) of sodium hydroxide into 35 parts (in liters) of water glass with a modulus of 3.7 while stirring, and dilute with water 10 times to make an activator for later use, that is, the volume content of dilution water is 10 times the total volume of sodium hydroxide and water glass after mixing. Add 1 part by weight (in kilograms) of 200-mesh calcined kaolin powder to 1 part by volume (in liters) of the activator prepared in the previous step, and stir evenly to make a binder for later use. Add 1 part of volume (in liters) of binder to 1 part of weight (in kilograms) of the mixed mineral powder raw material prepared in the first step. Wetness is the criterion for judging. Then, rod-shaped granules with...

Embodiment 2

[0046] 1 part (by kilogram) of 80 mesh diatomite powder plus 4 parts (by kilogram) of 325 mesh attapulgite clay powder and 15 parts (by kilogram) of 325 mesh natural clinoptilolite powder, fully mixed in a mixer, Made into powder raw materials for later use. Add 1 part (in kilograms) of sodium hydroxide into 25 parts (in liters) of water glass with a modulus of 2.2 while stirring, and dilute it with water 5 times to prepare an activator for use. Add 1 part by weight (in kilograms) of 325-mesh metakaolin powder to 2 parts by volume (in liters) of the activator aqueous solution prepared in the previous step, and stir evenly to make a binder for later use. Add 1 part by volume (by liter) of binder to 1 part by weight (by kilogram) of the mixed mineral powder raw material prepared in the first step, knead and stir until semi-wet. Granulate by extrusion granulator. Cured at room temperature for 6 days.

[0047] After 6 days, the hardness of the material reaches 40N / grain, NH 4 ...

Embodiment 3

[0049] 1 part (by kilogram) of natural clinoptilolite is crushed to 325 mesh for later use. Add 1 part (in kilograms) of sodium hydroxide into 5 parts (in liters) of water glass with a modulus of 2.5 while stirring, and dilute with water 3 times to make an activator for later use. Add 1 part by weight (in kilograms) of 325-mesh fly ash to 1 part by volume (in liters) of the activator aqueous solution prepared in the previous step, and stir evenly to make a binder for later use. Add about 1 volume (in liters) of binder to 2 weights (in kilograms) of natural clinoptilolite powder, knead and stir until semi-wet. It is then granulated by an extrusion granulator. Moisturize for 5 days at room temperature.

[0050] After 5 days, the hardness of the material reaches 75N / grain, NH 4 + The ion exchange capacity is 160mmol / 100g, the saturated exchange capacity is 12.1mg / g, the ammonium absorption capacity reaches 10mg / g, the porosity is 38%, the bulk density is 0.82, and the BET spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com