Vinyl chloride monomer unloading method

A technology of vinyl chloride monomer and vinyl chloride, which is applied in liquid flow control devices, liquid distribution, liquid distribution, transportation or transfer devices, etc. Slow polymerization reaction rate and other problems, to achieve the effect of being conducive to the control of production costs, avoiding adverse effects, and ensuring purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with embodiment the present invention is described in further detail, but protection scope of the present invention is not limited to these examples:

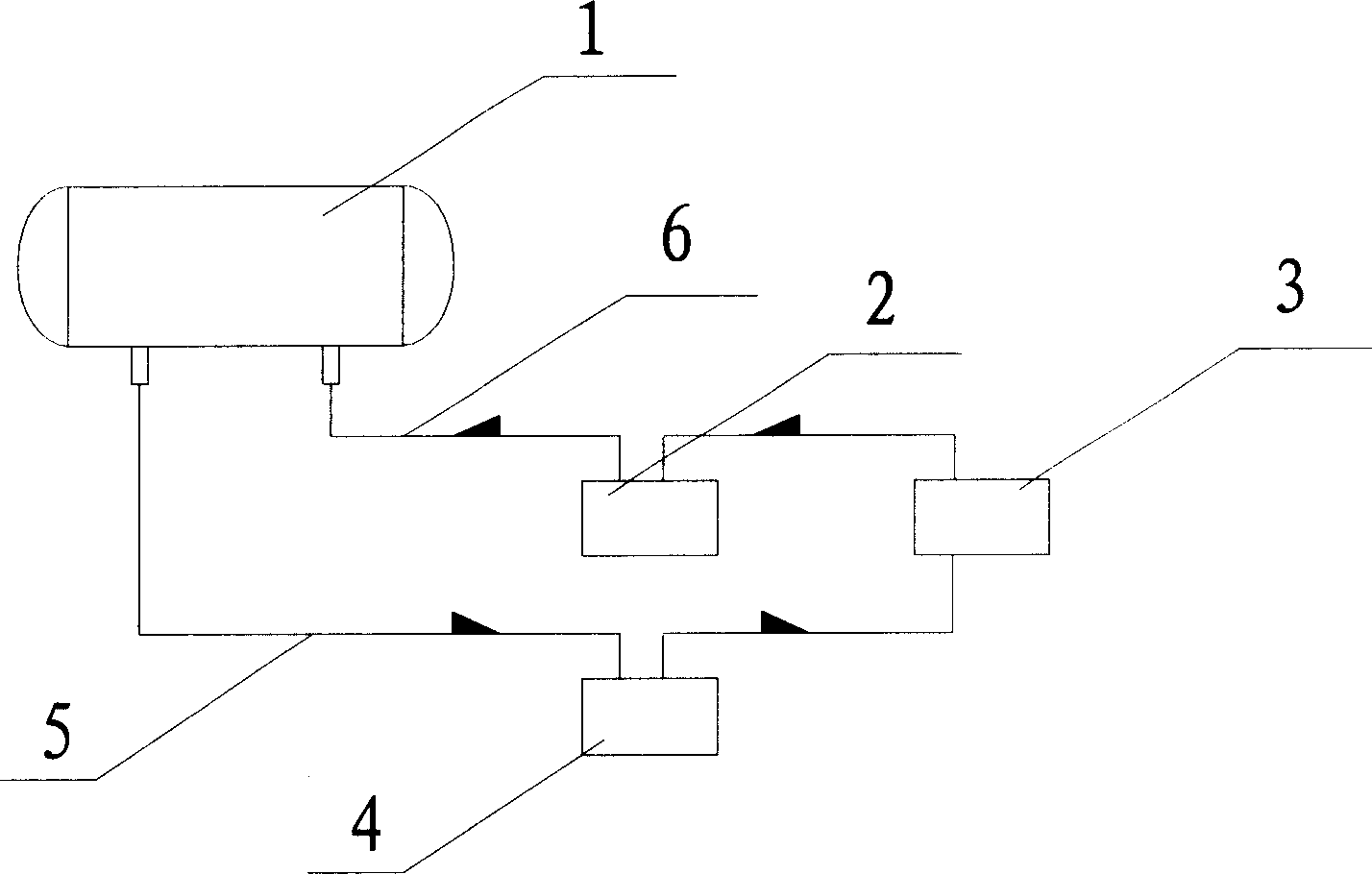

[0013] A method for unloading vinyl chloride monomer. A discharge channel 5 is provided between the tank car 1 and the monomer storage tank 3, and a gas phase balance pipe 6 between the tank car 1 and the monomer storage tank 3 is installed Vinyl chloride monomer compressor 2, the compressor 2 can pressurize the gaseous vinyl chloride monomer as required; when unloading, first open the vinyl chloride monomer compressor 2, pump the gaseous vinyl chloride monomer in the monomer storage tank 3 Pressurize into the vinyl chloride monomer compressor 2, and then pressurize the pressurized gaseous vinyl chloride monomer into the tank car 1, so that the pressure in the tank car 1 is always higher than the saturated vapor pressure of the vinyl chloride monomer, and at A pressure difference is formed between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com