Integrated vacuum rectification equipment for vegetable oil

A technology for vacuum distillation and vegetable oil, which is applied in vacuum distillation, fat oil/fat refining, chemical instruments and methods, etc., can solve the problems of complex structure, high manufacturing cost, inconvenient to popularize and implement, etc. The effect of uniform heating and easy promotion and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

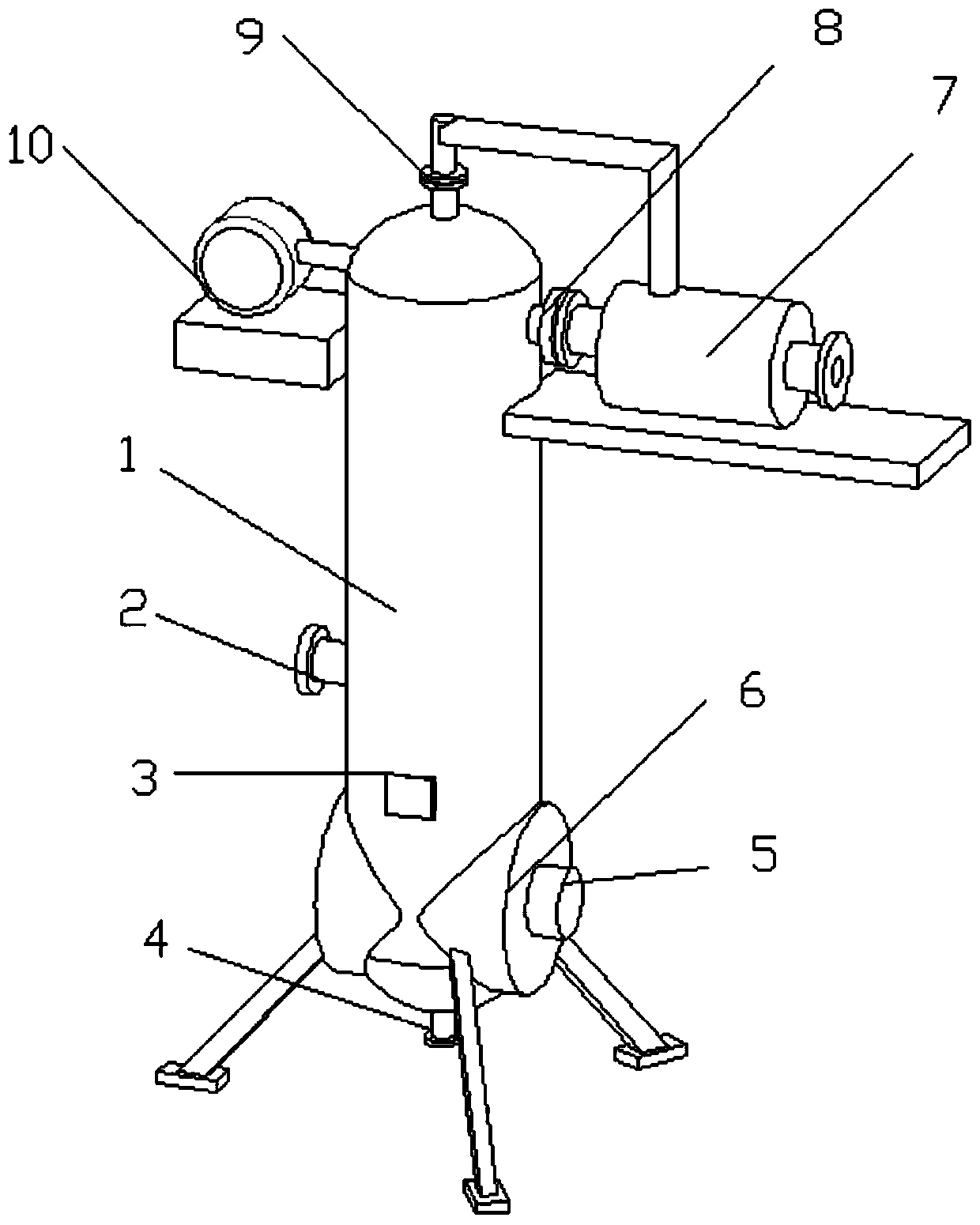

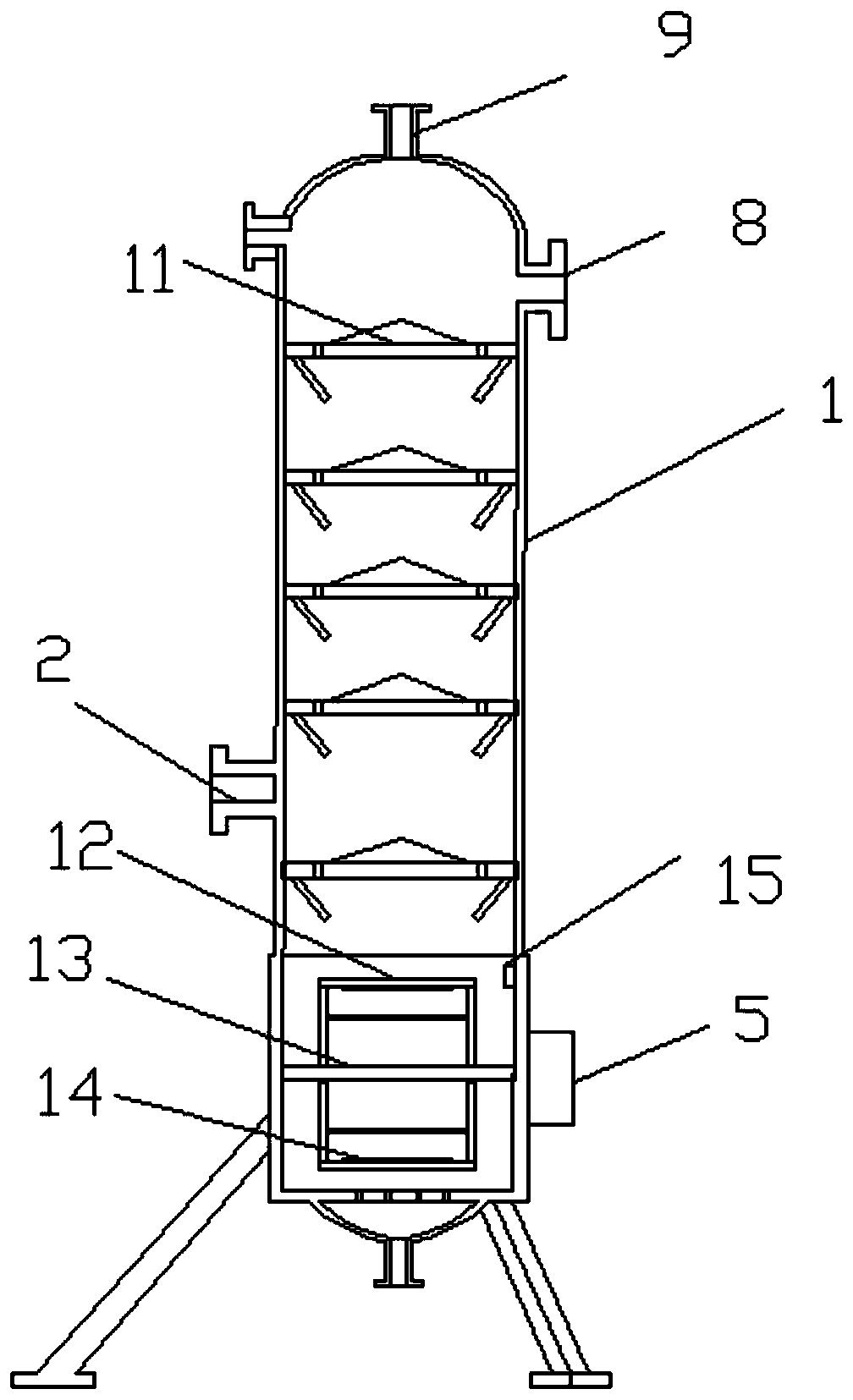

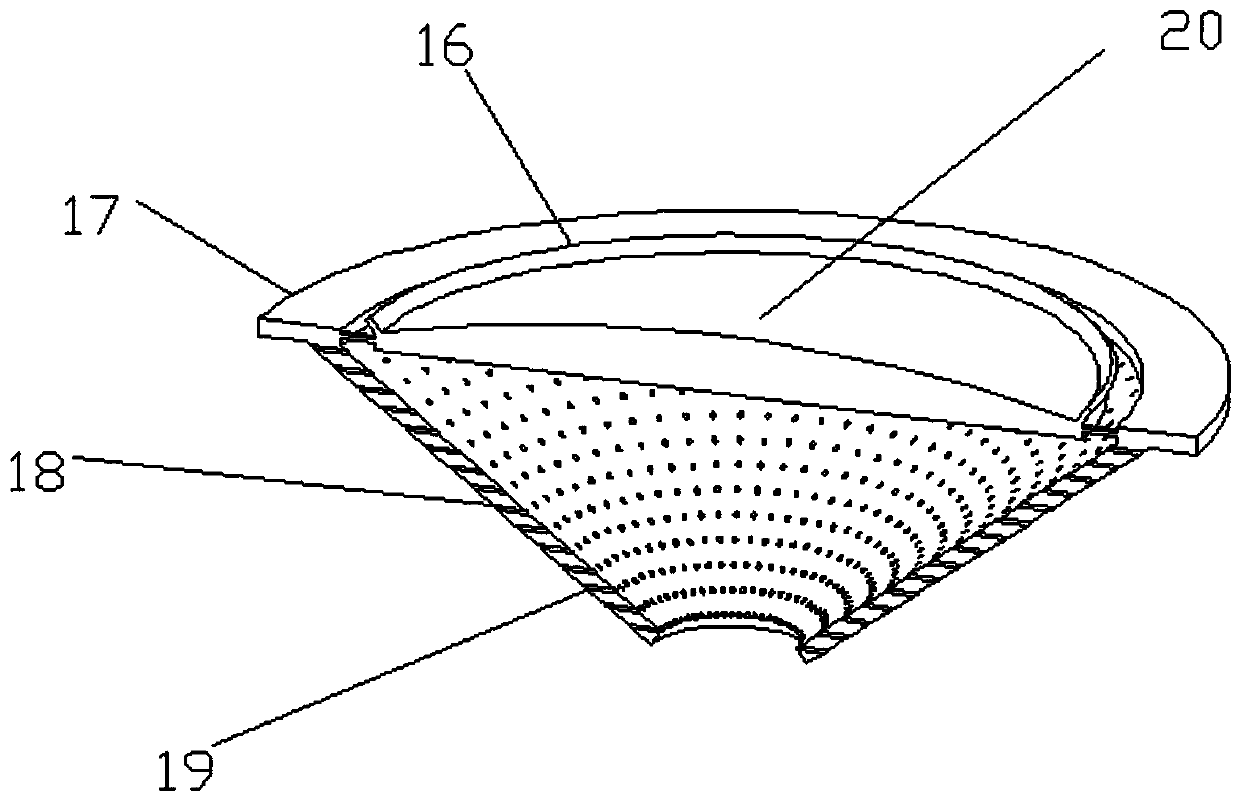

[0021] see Figure 1-3 , vacuum rectification vegetable oil integrated equipment, including a tower body 1 and a heating kettle body 6, the tower body 1 is connected to the top of the heating kettle body 6, the upper end of the tower body 1 is connected with a vacuum pump 10, under the action of the vacuum pump 10, the tower Negative pressure is formed inside the body 1 and the heating kettle body 6, which is convenient for rectification. The top of the tower body 1 is provided with a gas outlet 9, and the gas outlet 9 is connected to a reflux device 7, and the reflux device 7 is connected to the reflux port 8 provided on the side wall of the top of the tower body 1, and the steam enters from the gas outlet 9 to the side of the reflux device 7. The interior is cooled, and the heavy component enters the interior of the tower body 1 from 8 for reflux. The side wall of the tower body 1 is provided with a feed port 1, and the raw material enters the interior of the tower body 1 fr...

Embodiment 2

[0026] On the basis of Example 1, a number of through holes 19 are opened on the guide member 18. The setting of the through holes 19 increases the contact probability of gas and liquid, thereby facilitating the exchange of light components and improving the quality of rectification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com