TiO2-WO3 composite nano powder and preparation method thereof, SCR denitration catalyst and flue gas denitration method

A denitration catalyst, tio2-wo3 technology, which is applied in the field of denitration, can solve the problems of low denitration efficiency of the denitration catalyst, small specific surface area of nano-powder, long preparation process, etc., and achieves reduced operating conditions and equipment requirements, low cost and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

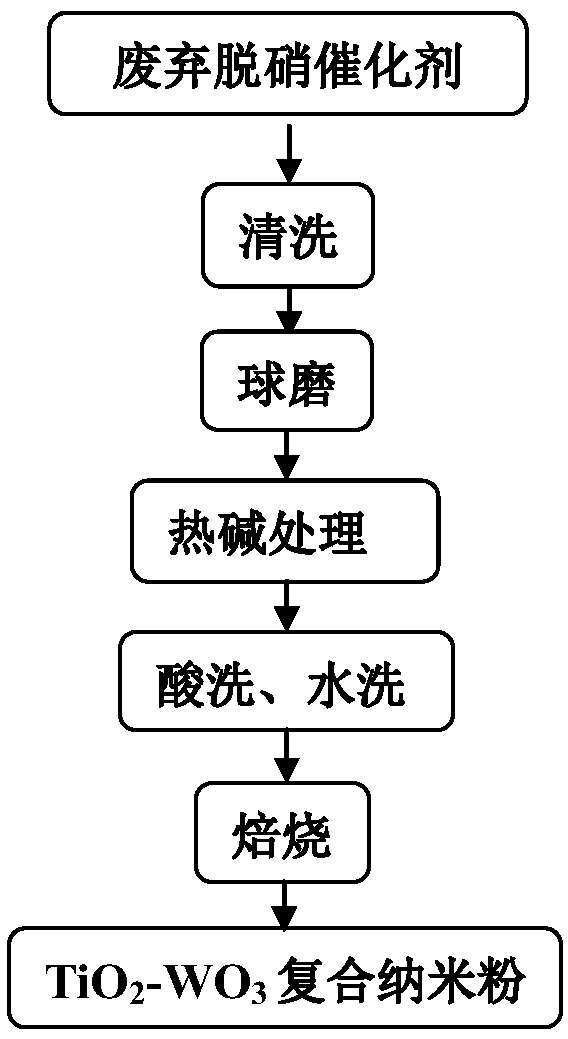

[0030] The first aspect of the present invention provides a TiO 2 -WO 3 The preparation method of composite nanopowder, wherein, the method comprises the following steps:

[0031] (1) cleaning and ball milling the waste denitration catalyst to obtain pulverized granules, and adding a strong alkali solution for hot alkali treatment and first filtration to obtain filter residue;

[0032] (2) pickling and washing the filter residue with water, and second filtering to obtain titanium-tungsten raw powder;

[0033] (3) Roasting the titanium-tungsten raw powder to obtain TiO 2 -WO 3 Composite nanopowder.

[0034] According to the method of the present invention, the waste denitration catalyst is a titanium-based vanadium-tungsten-based honeycomb, corrugated or flat-plate denitration catalyst.

[0035] According to the method of the present invention, the cleaning includes ultrasonic cleaning and rinsing, preferably, the time of the ultrasonic cleaning is 10-60 min, and the time ...

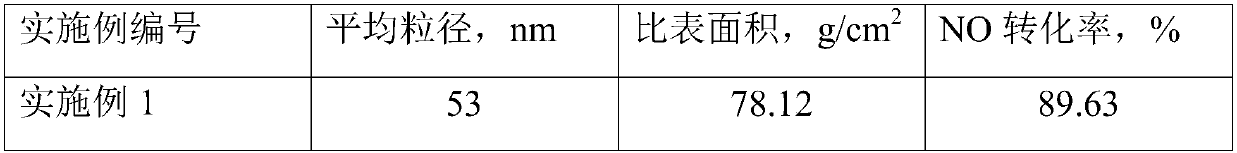

Embodiment 1

[0053] Clean the waste SCR denitrification catalyst ultrasonically for 60 minutes, then rinse it for 60 minutes, ball mill it to 200 mesh, take 100 g of the waste denitration catalyst after ball milling and put it in a 500 ml flask, add 100 ml of NaOH with a concentration of 30% by weight and react at 145°C for 3 hours , filter to obtain a filter residue, the filter residue is washed with a sulfuric acid solution with a concentration of 3% by weight at 30°C until the pH is 6, and then the filter residue is washed with deionized water until the conductivity is 100 μS / cm, and filtered to obtain titanium-tungsten Raw powder, the titanium-tungsten raw powder is calcined according to the following roasting system: from room temperature to 100°C at a constant temperature for 2 hours at a rate of 3°C / min; then at a rate of 3°C / min to 200°C for 2 hours at a constant temperature ; Then heat up to 400°C at a constant temperature for 2.5 hours at a rate of 2°C / min; finally heat up at a ra...

Embodiment 2

[0056] Ultrasonic cleaning of the waste SCR denitration catalyst for 30 minutes, then rinsing for 30 minutes, ball milling to 400 mesh, taking 100 g of ball milled waste denitration catalyst and placing it in a 1500ml flask, adding 1000ml of NaOH with a concentration of 20% by weight and reacting at 100°C for 5 hours , filter to obtain a filter residue, the filter residue is washed with a sulfuric acid solution having a concentration of 5% by weight at 100°C until the pH is 1, and then the filter residue is washed with deionized water until the conductivity is 38 μS / cm, and filtered to obtain titanium-tungsten Raw powder, the titanium-tungsten raw powder is calcined according to the following roasting system: from room temperature to 200°C at a constant temperature for 1 hour at a rate of 1°C / min; then at a rate of 1°C / min to 300°C for 1 hour at a constant temperature ; Then heat up to 450°C for 2 hours at a rate of 1°C / min; finally heat up to 850°C for 2 hours at a rate of 1°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com