Method for preparing flocculant for efficient settling separation of high-silicon and high-iron type red mud generated through Bayer process

A Bayer red mud and sedimentation separation technology, which is applied in the field of flocculant preparation, can solve problems such as difficulty in meeting high-efficiency flocculation requirements, unknown content of hydroxamic acid groups, easy decomposition of quaternary ammonium bases, etc., to meet industrial requirements, reaction The effect of optimized conditions and simple synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

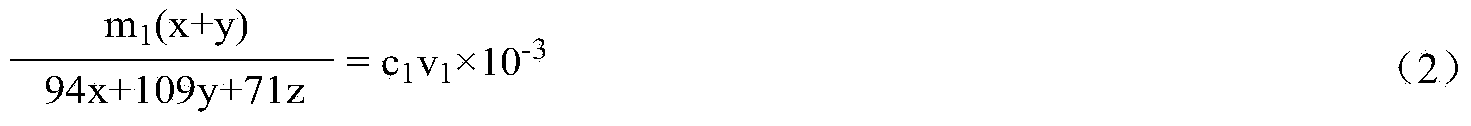

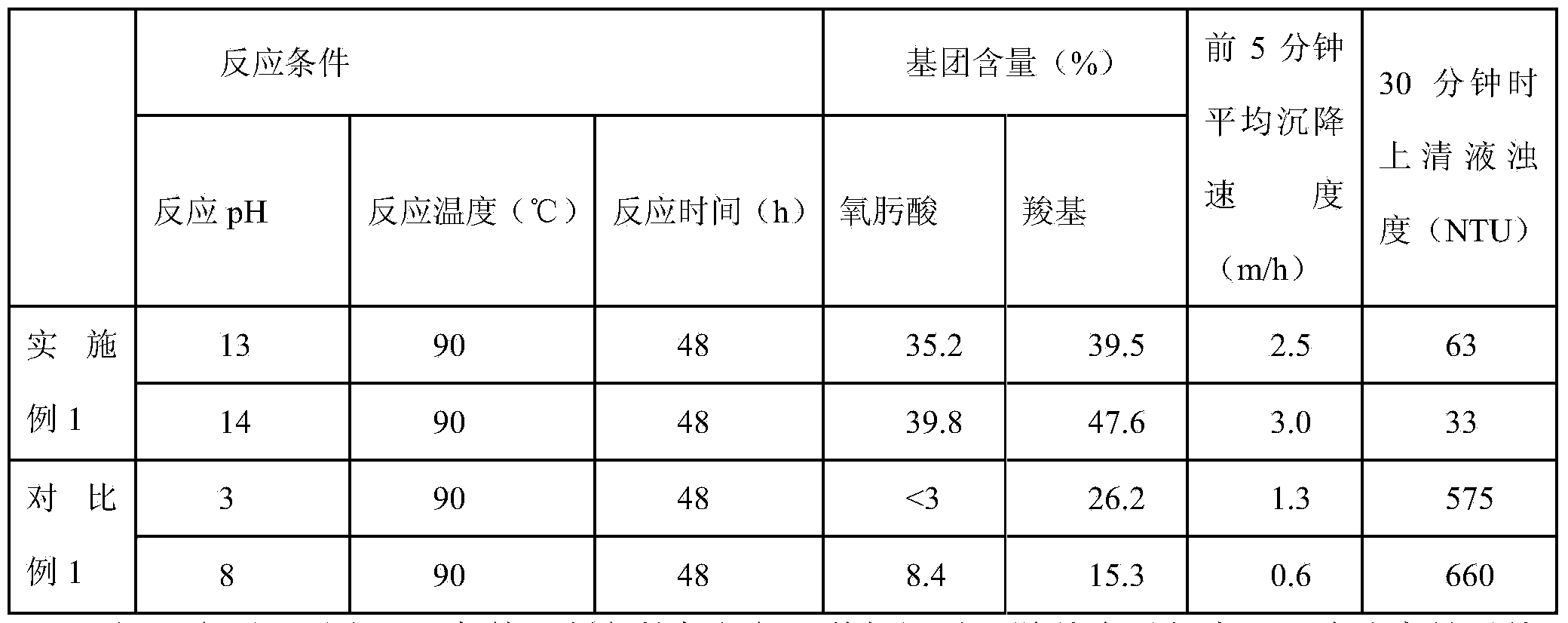

[0018] Preparation of Flocculant Containing Hydroxamic Acid and Carboxyl Group at the Same Reaction pH Conditions

[0019] 1) Dry high molecular weight polyacrylamide (mass average molecular weight of 20-30 million, intrinsic viscosity of 1200-1750mL / g) in a vacuum drying oven at 50°C for 12 hours, weigh 3.505g into a 250mL three-necked round bottom flask, Add 100mL of distilled water, stir in a 40℃ water bath, 45-60r / min for 3h to dissolve the high molecular weight polyacrylamide completely;

[0020] 2) Under a nitrogen atmosphere, dissolve hydroxylamine hydrochloride in an equimolar sodium hydroxide solution, slowly add it dropwise to the polyacrylamide solution obtained in step 1) with a dropping funnel to control the hydroxylamine hydrochloride and polyacrylamide The molar ratio of the amide groups is 1.2~1.5;

[0021] 3) The control conditions of the entire reaction process: 45-60r / min mechanical stirring, 20-40g / L NaOH is used to adjust the pH of the aqueous reaction system to...

Embodiment 2

[0024] Preparation of Flocculant Containing Hydroxamic Acid and Carboxyl Group at the Same Reaction Temperature

[0025] Except that the reaction process conditions are: the pH of the reaction system is 14, the reaction temperature is 90-100° C., and the reaction time is 48 h, the flocculant is prepared in the same manner as in Example 1.

Embodiment 3

[0027] Preparation of flocculant containing both hydroxamic acid and carboxyl group under different reaction time conditions

[0028] Except that the reaction process conditions are: the pH of the reaction system is 14, the reaction temperature is 90° C., and the reaction time is 24 to 48 h, the flocculant is prepared in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com