A preparation method of a flocculant for effectively settling and separating high-silicon and high-iron type Bayer red mud

A Bayer red mud and sedimentation separation technology, which is applied in the field of flocculant preparation, can solve problems such as difficult to meet high-efficiency flocculation requirements, unknown hydroxamic acid group content, loss of flocculation, etc., to meet industrial requirements and optimize reaction conditions , the effect of simple synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

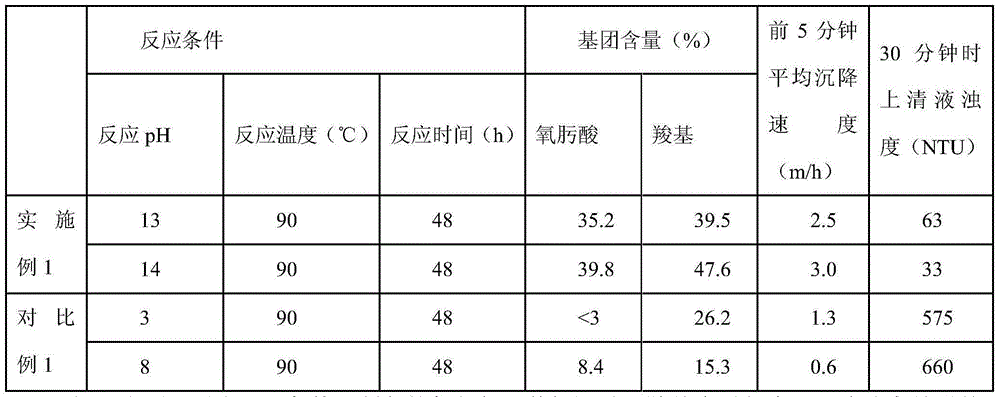

[0018] Preparation of flocculants containing both hydroxamic acid and carboxyl groups under different reaction pH conditions

[0019] 1) Dry high-molecular-weight polyacrylamide (mass-average molecular weight 20-30 million, intrinsic viscosity 1200-1750mL / g) in a vacuum oven at 50°C for 12 hours, weigh 3.505g and add it to a 250mL three-necked round-bottomed flask. Add 100mL of distilled water, and mechanically stir in a 40°C water bath at 45-60r / min for 3h to completely dissolve the high-molecular-weight polyacrylamide;

[0020] 2) Under a nitrogen atmosphere, dissolve hydroxylamine hydrochloride in an equimolar ratio of sodium hydroxide solution, and slowly add it dropwise to the polyacrylamide solution obtained in step 1) with a dropping funnel, to control the concentration of hydroxylamine hydrochloride and polyacrylamide The molar ratio of the amide groups is 1.2 to 1.5;

[0021] 3) Control conditions of the whole reaction process: 45-60r / min mechanical stirring, use 20-...

Embodiment 2

[0024] Preparation of Flocculants Containing Hydroxamic Acid and Carboxyl Groups at Different Reaction Temperatures

[0025] The flocculant was prepared according to the same method as in Example 1, except that the reaction process conditions were: the pH of the reaction system was 14, the reaction temperature was 90-100° C., and the reaction time was 48 hours.

Embodiment 3

[0027] Preparation of flocculants containing both hydroxamic acid and carboxyl groups under different reaction time conditions

[0028] The flocculant was prepared according to the same method as in Example 1, except that the reaction process conditions were: the pH of the reaction system was 14, the reaction temperature was 90° C., and the reaction time was 24-48 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com