Unpowered automatic-adjustment cloth bag dust removal device

A bag dust removal and automatic adjustment technology, applied in transportation and packaging, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of bag rupture, uneven air distribution, small cross-sectional area of air inlet, etc., and achieve uniform filtration load , the service life is improved, and the effect of improving the filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

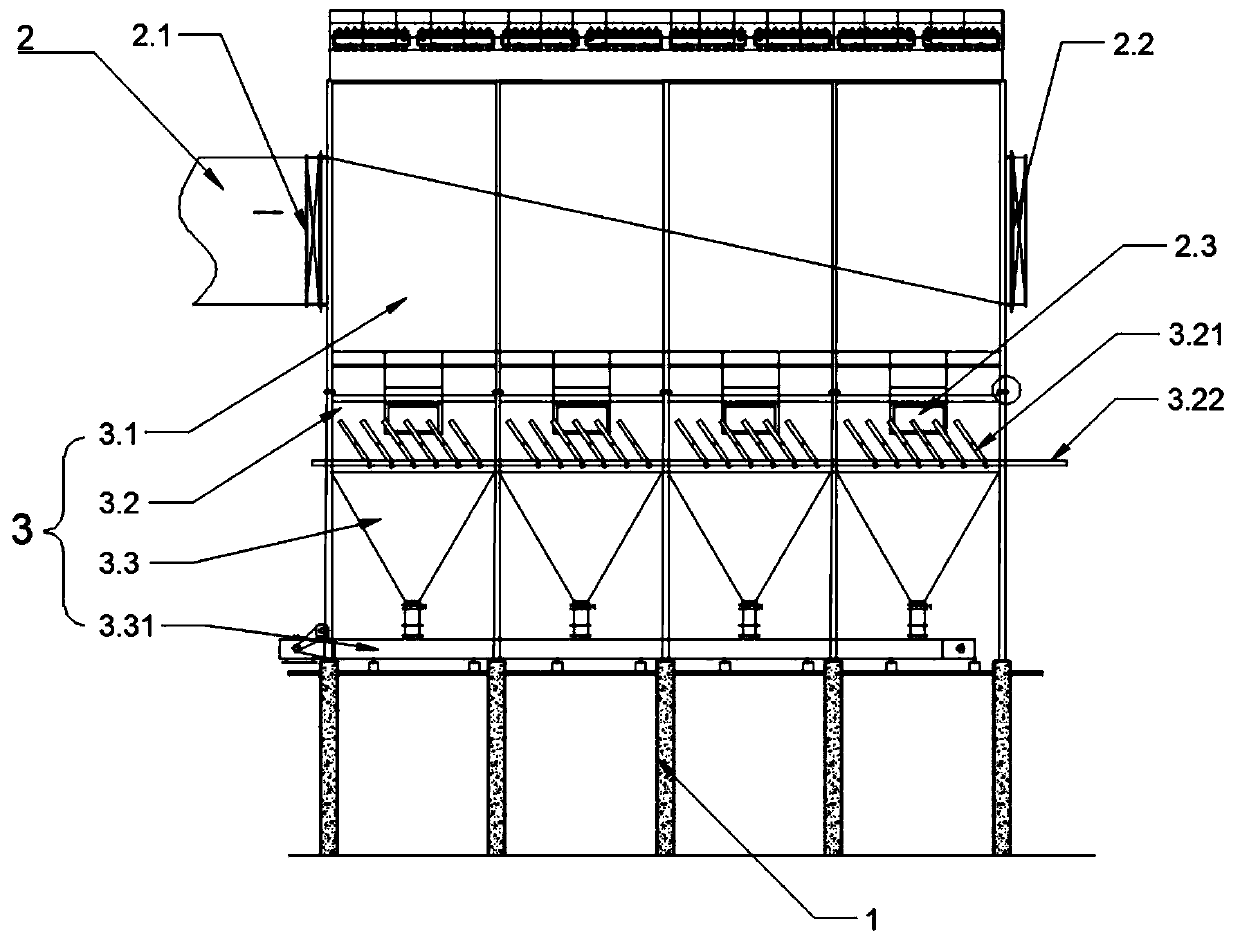

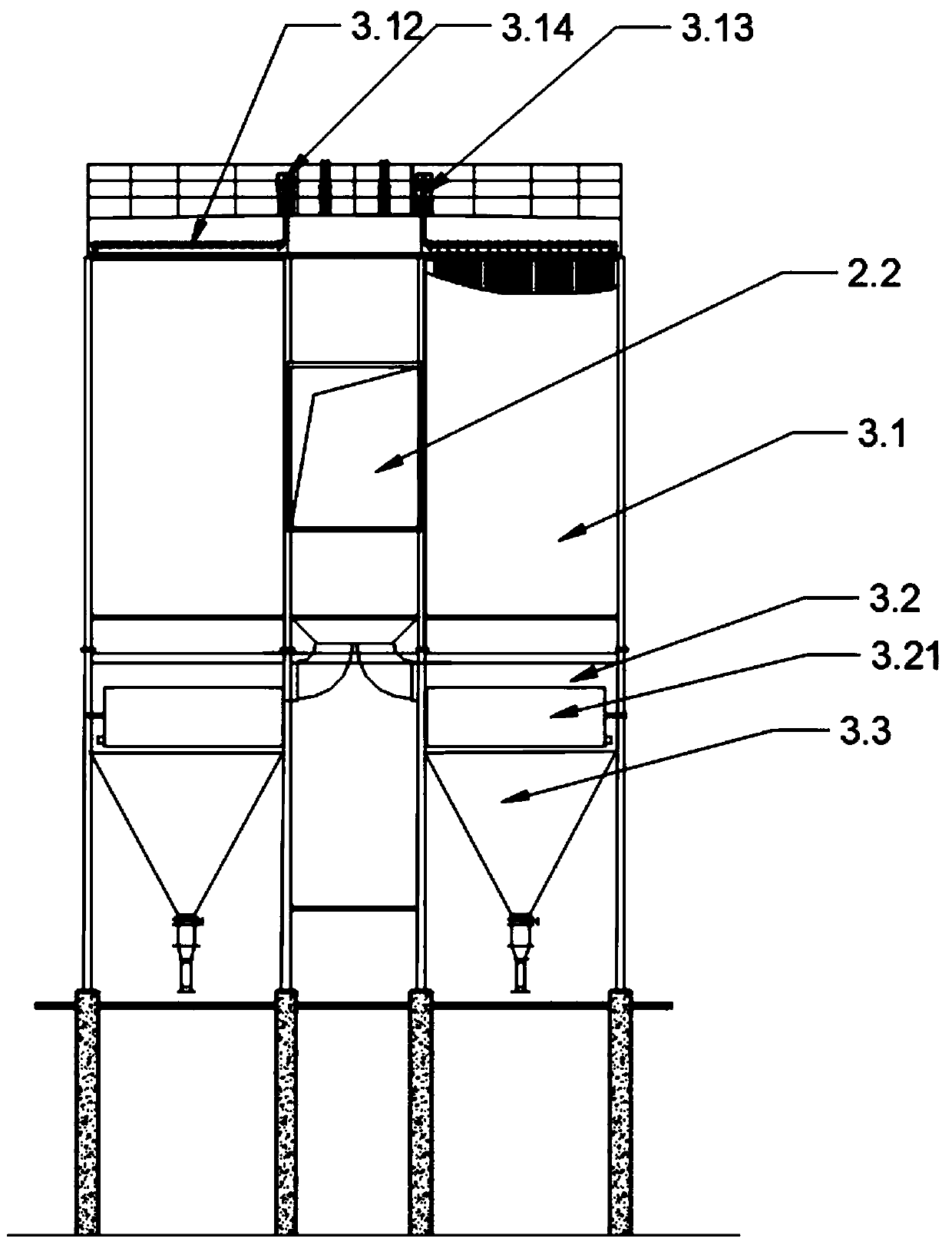

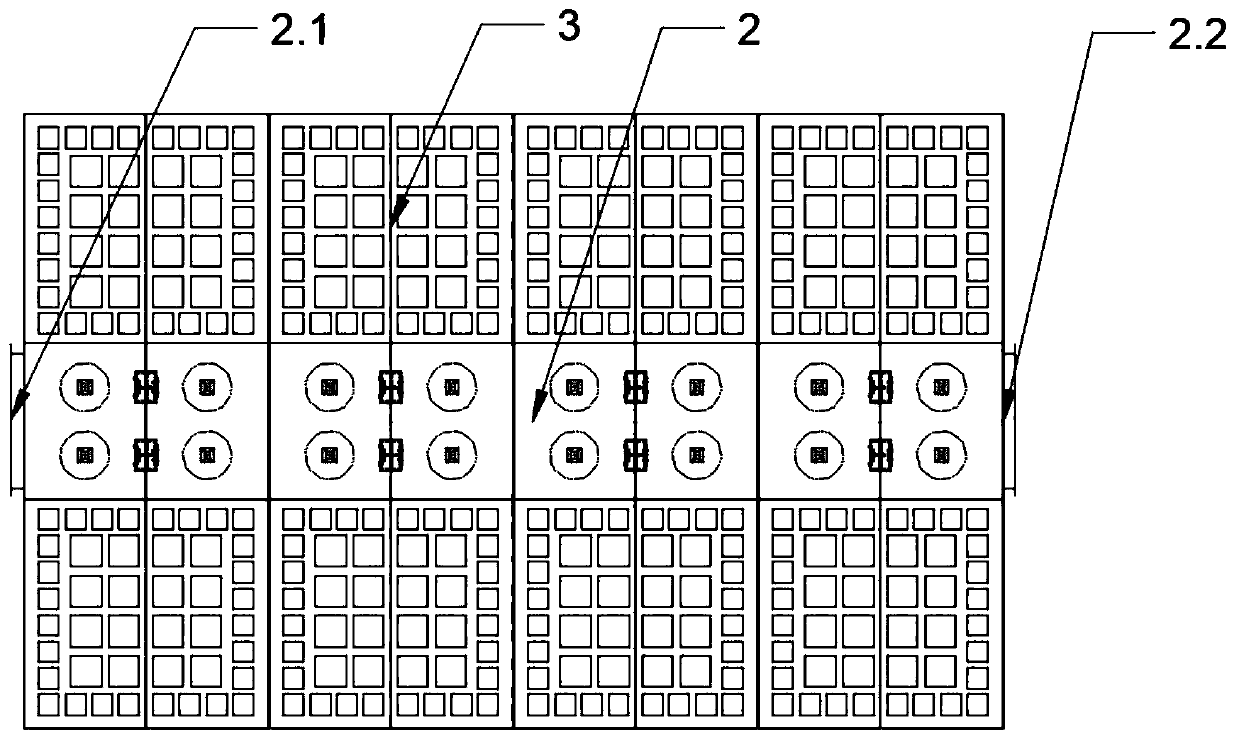

[0028] In order to clearly illustrate the technical features of the present solution, the present invention will be described in detail below through specific implementations and in conjunction with the accompanying drawings.

[0029] Such as Figure 1-4 As shown, the present invention provides a non-powered automatic adjustment bag dust removal device, including an outer frame 1, a bag dust removal ventilation duct 2 arranged on the outer frame 1, and eight sets of two side by side arranged in the bag dust removal ventilation duct 2 The bag dust collector 3 on the side; the bag dust removal ventilation duct 2 horizontally penetrates the outer frame 1, and is equipped with an air inlet 2.1 and an air outlet 2.2, the bag dust removal ventilation duct 2 includes an air outlet channel stacked one above the other And the air inlet channel, the air outlet channel and the air inlet channel are divided into two upper and lower wedge-shaped channels by an inclined baffle, wherein the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com