A Chip Liquid Jet Cooling Equipment Based on Aluminum Alloy Processing

A technology for cooling equipment and cutting fluid, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of affecting recycling, poor purity of cutting fluid, poor separation effect of iron filings, etc., to increase the circulation path , Longer flowing time, better cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

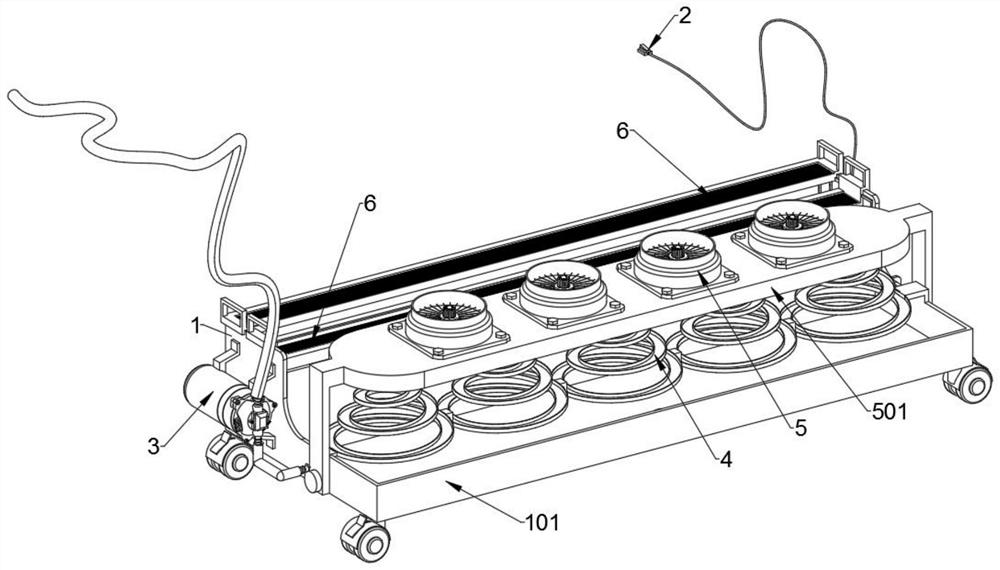

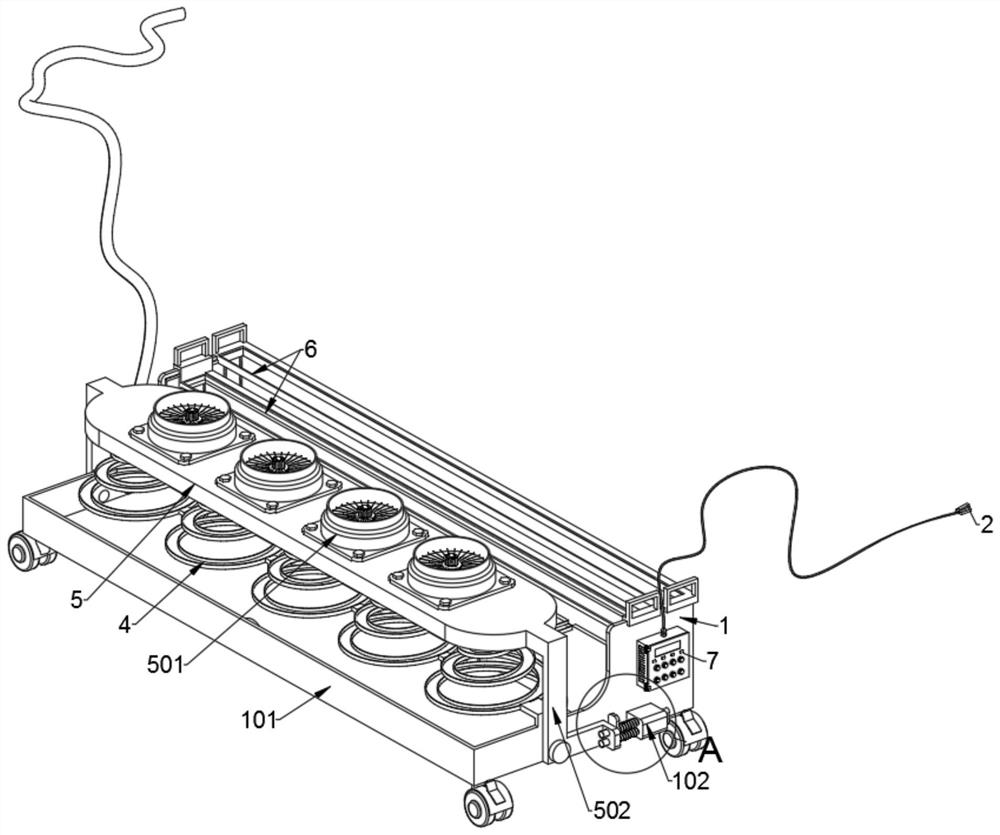

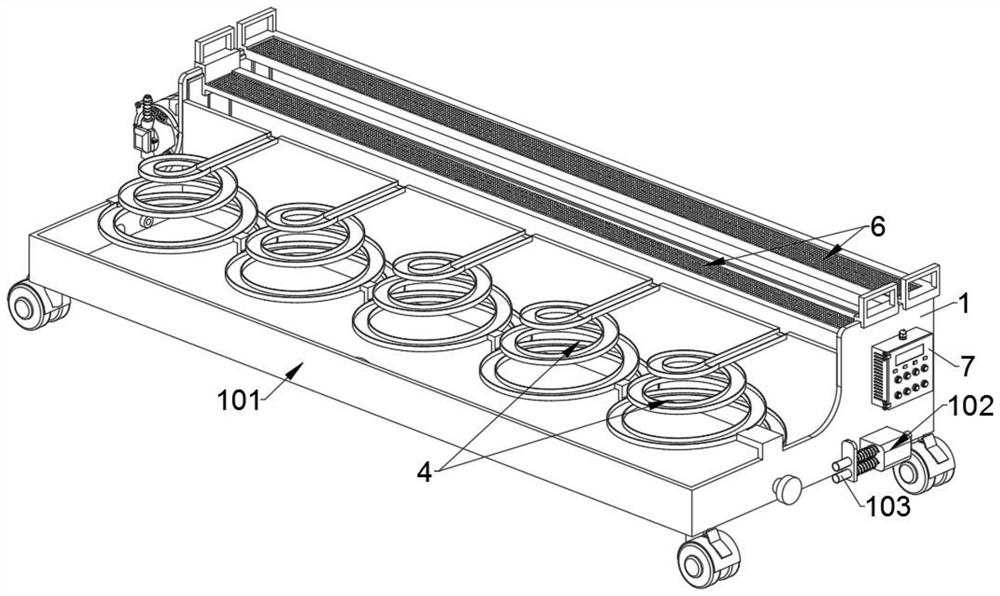

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035] The present invention provides a chip liquid spray cooling device based on aluminum alloy processing, which includes a rectangular liquid tank 1, a water receiving tray 101, a positioning block 102, an insertion rod 103, a partition plate 104, a remote control switch 2, an electric pump 3, Spiral pipe groove 4, air distribution box 5, heat dissipation fan 501, support plate 502, filter frame 6 and control electrical box 7; the inner middle of described rectangular liquid tank 1 supports and is provided with a spacer plate 104, and this spacer plate 104 will The inner space of the rectangular liquid storage tank 1 is divided into two water storage chambers at the front and rear; a flat rectangular water receiving tray 101 is connected to the front side of the rectangular liquid storage tank 1; on the left side wall of the rectangular liquid storage tank 1 An electric pump 3 is installed, and the water inlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com