Solid-liquid separator

A solid-liquid separation and clear liquid technology, applied in the sedimentation tank and other directions, can solve the problems of unsatisfactory effect and low recovery rate, and achieve the effect of less particle size, good effect and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

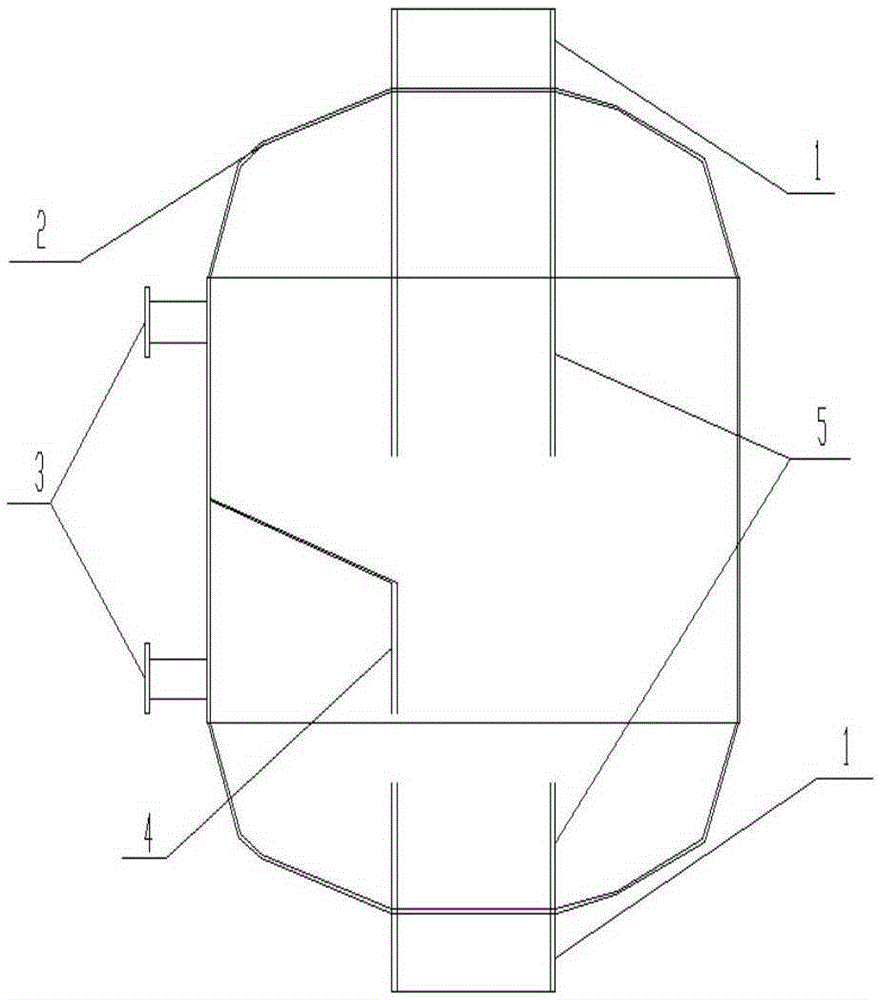

[0010] The solid-liquid separator, as a kind of solid-liquid separation equipment, is divided into upper and lower circular head cylinders 1, straight cylindrical cylinders, and the DC baffle 5 and baffle 4 are welded inside the equipment. Among them, the circulation pipe 1 is a part of the forced circulation evaporator, and the solid-liquid separator, as a separation device, is connected to the forced circulation pipe and connected to the upper and lower heads of the cylinder by welding; The liquid outlet 3 is fixed on the straight cylinder through the flange, the distance between the center line of the supernatant outlet and the interface between the straight cylinder and the head is one tenth of the height of the straight cylinder, and the outlet of the supernatant and the outlet of the supernatant Symmetrically distributed in the straight section, where the diameter of the clear liquid outlet is one-fifteenth of the height of the straight section; the baffles are welded ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com