High-dielectric-constant three-phase composite material containing modified graphene and preparation method thereof

A high dielectric constant and composite material technology, applied in the field of dielectric materials, achieves the effect of simple process and low molding temperature

Inactive Publication Date: 2012-09-19

UNIV OF SCI & TECH BEIJING

View PDF1 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the content of ceramic particles in the composite material is more, which will reduce the toughness and bondability of the composite material.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

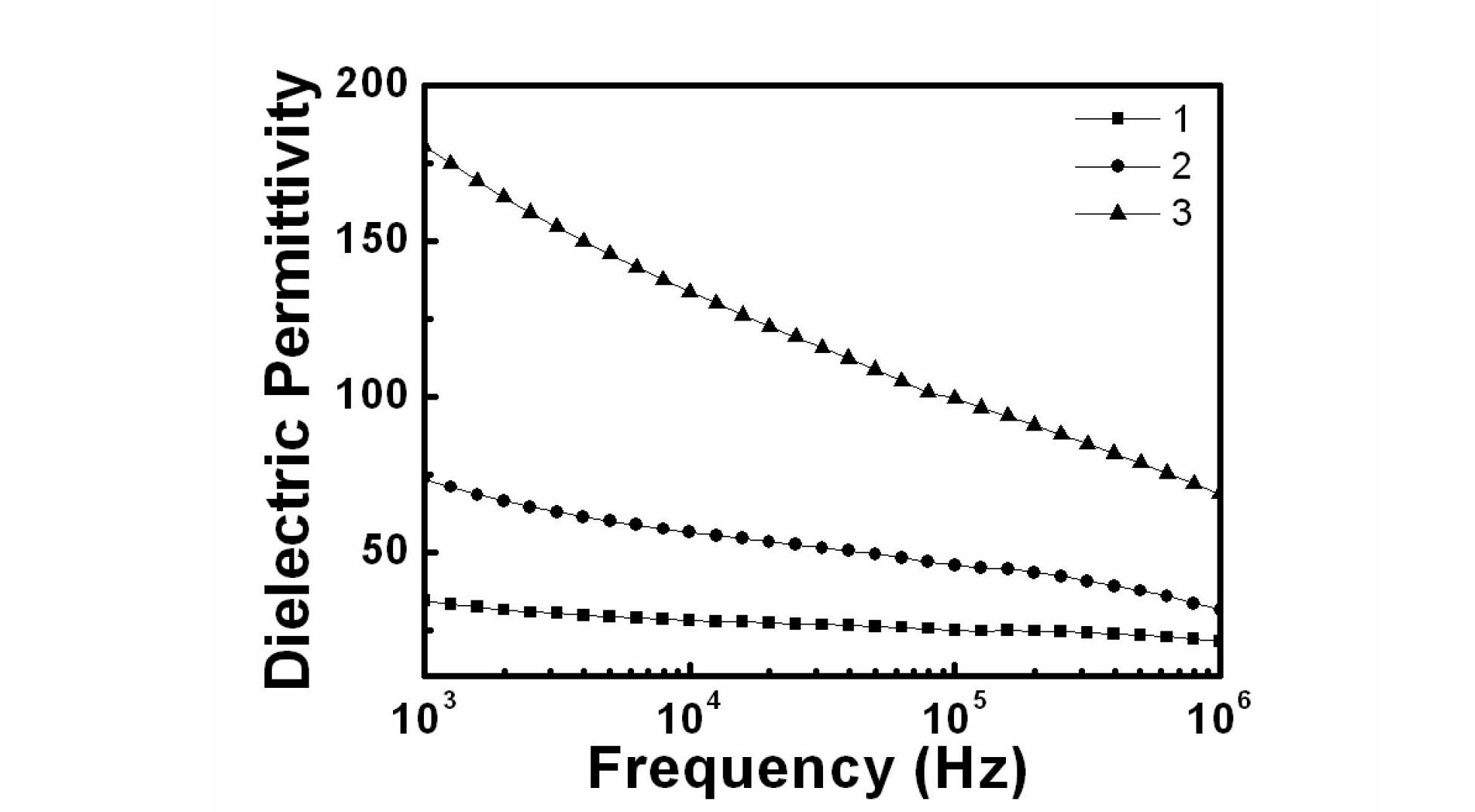

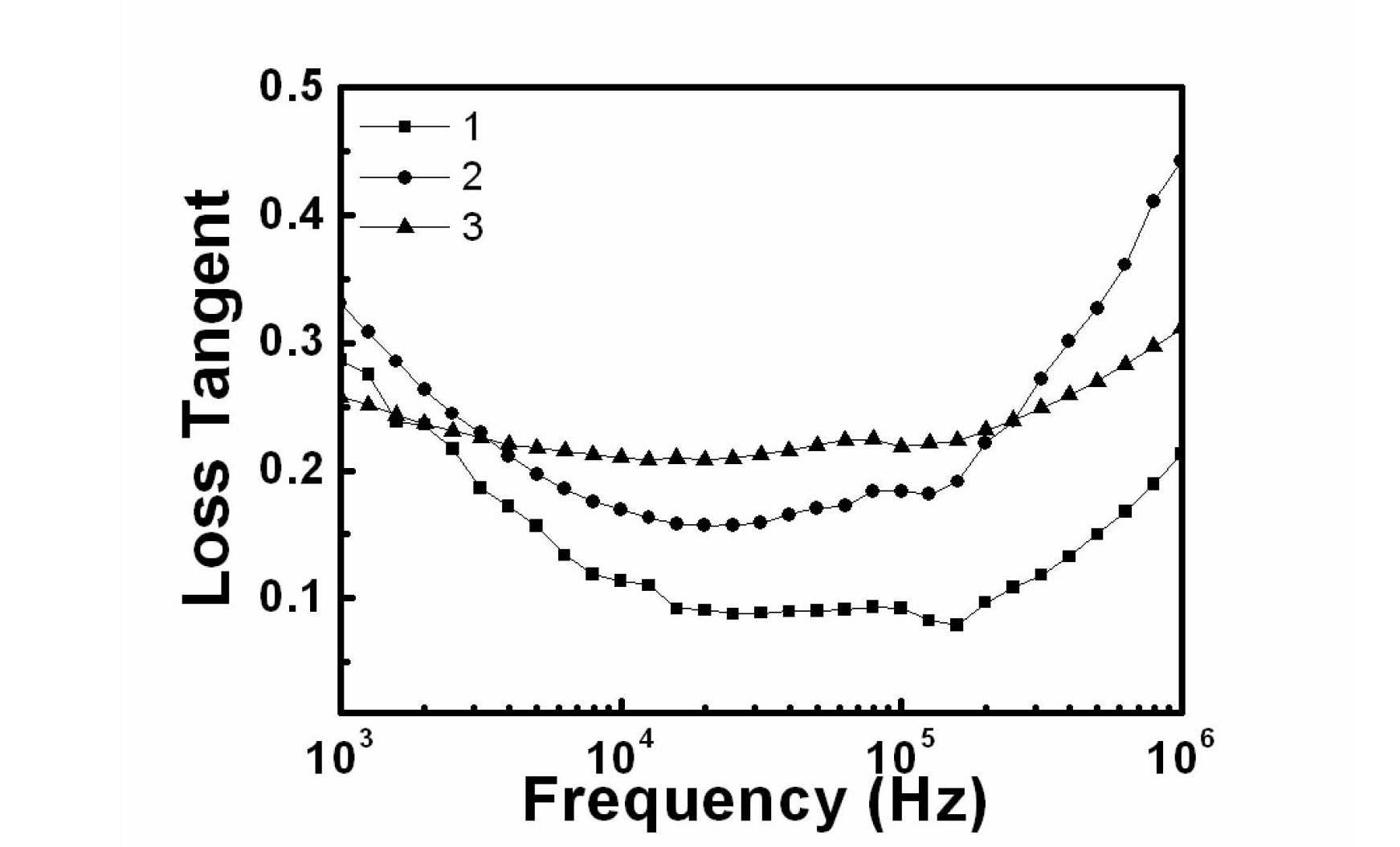

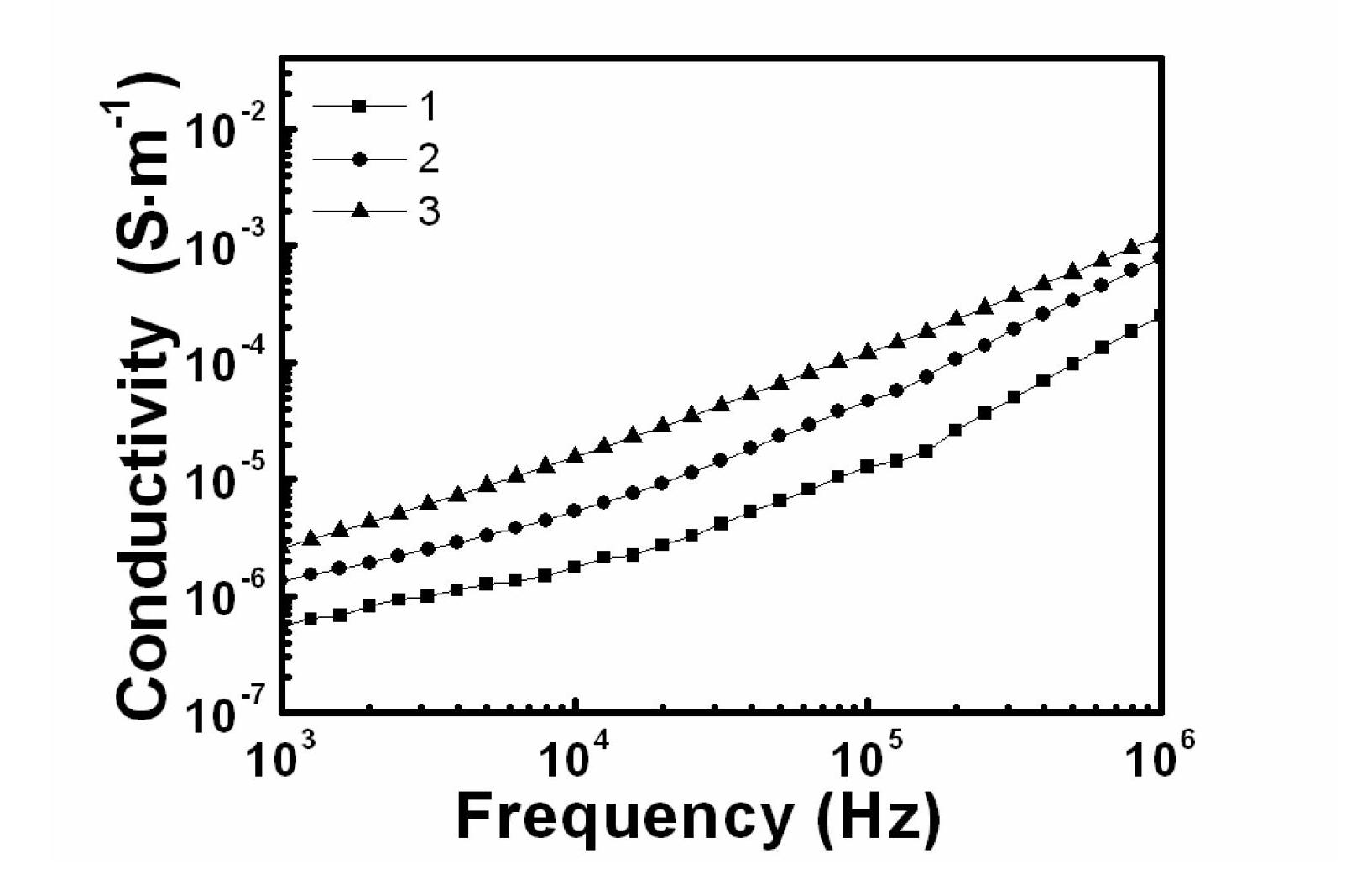

The invention discloses a high-dielectric-constant three-phase composite material containing modified graphene and a preparation method thereof, belonging to the field of dielectric medium materials. For realizing a high dielectric constant for the conventional polymer-based dielectric medium composite material, a large quantity of ceramic particles are required to be added into the composite material, resulting in damages to the mechanical property and electrical property of the composite material. The polymer-based dielectric medium composite material provided by the invention consists of three phases, i.e., polymer substrate polyvinylidene fluoride, filler particle barium titanate and eigen state polyaniline-modified graphene particles respectively. By introducing modified graphene particles into the composite material, the content of ceramic particles is reduced. A polymer is compounded with inorganic particles with a solution method, and the composite material is processed and molded by adopting a hot pressing process, so that an inorganic-polymer three-phase composite material is obtained finally. The composite material provided by the invention has the advantages of high dielectric constant, high adhesive property, simple preparation process and the like.

Description

Technical field [0002] The invention is the field of electronics materials, which involves a three -phase composite material and preparation method containing a modified graphene high -dielectric constant. Background technique With the development of the electronics industry in the direction of miniaturization, the buried capacitors have been widely used. The polymer -based electronic medium composite material is an ideal applied material that is used in an integrated capacitor. At present, the preparation of polymer -based medium composite materials mainly uses a large amount of ceramic particles or conductive particles with high -agency constants into the polymer for preparation., Batio 3 ) For inorganic scattered phases, the polymer base agency electrical composite material was prepared.In this composite material, BATIO 3 The volume score reaches 40%, but the dielectric constant of the composite material is only 49. Another example, Chen zhang et al. 3 ?? Epoxy Composite M...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L27/16C08K13/06C08K3/24C08K9/04C08K3/04

Inventor 党智敏周涛查俊伟

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com