Optoelectronic package and fabrication method

A packaging, optoelectronic technology, applied in optical components, electrical components, electro-solid devices, etc., can solve problems such as high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

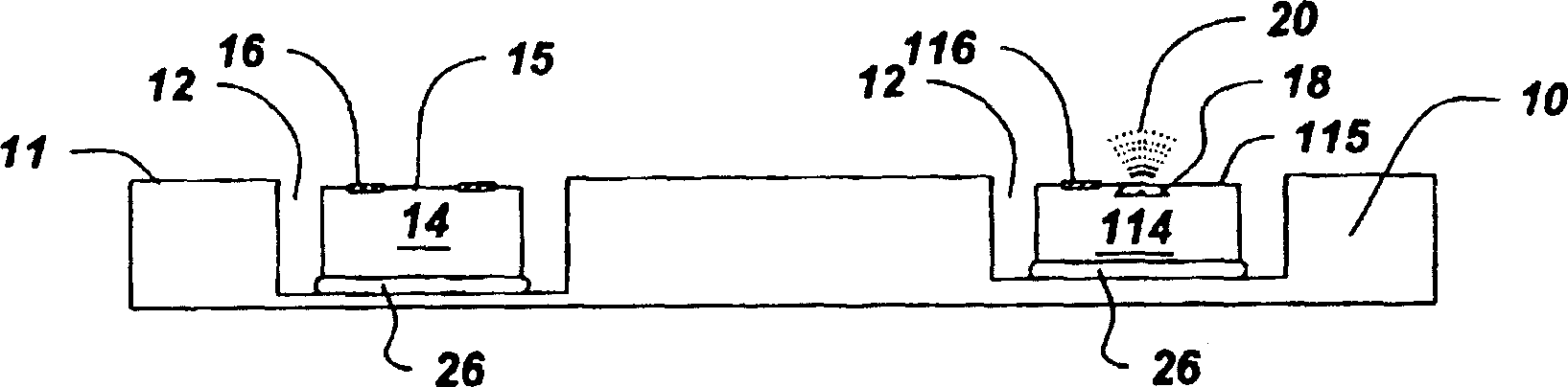

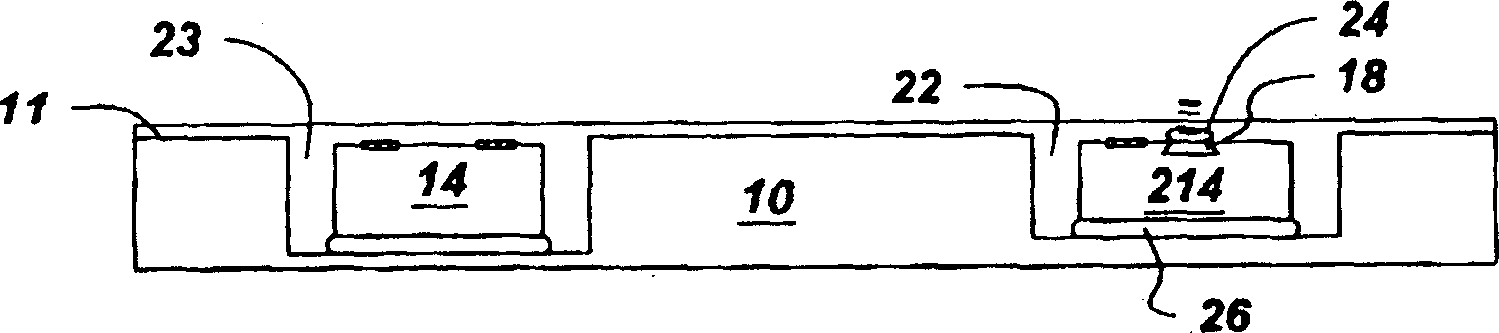

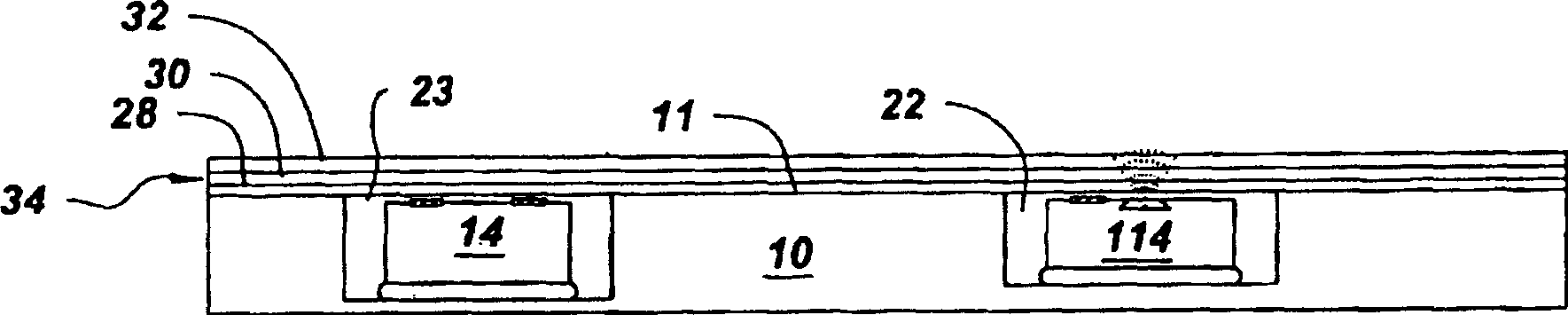

[0013] According to an embodiment of the present invention, a method for making an optoelectronic package 1 ( Figure 10 ), 101( Figure 17 ), 201( Figure 23 ), 301( Figure 20 ) method comprising: (a) disposing an optical device 114, 214, 314, 414, 514 (representing at least one optical device) within a window 12, 112, 212, 312 of a substrate 10 with the active side 115 up and at Below the substrate top surface 11 ( figure 1 , 12, 18 and 21); (b) fill the window with optical polymer material 22, 122, 222, 322 ( figure 2 , 12, 18 and 22); (c) planarizing the surface of the optical polymer material and substrate; (d) patterning (pattern) waveguide material 34, 134, 234, 334 on the substrate and optical polymer material, Optical interconnect channel 27 (at least one) is formed, and mirror 38 (at least one) is formed to reflect light from the optics to the interconnect channel ( Figure 3-4 , 13-14, 18, 22); and (e) form a via (via) 44 (at least one) to expose the bonding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com