Polymer optical fiber characteristic parameter testing apparatus and its testing method

A tester and polymer technology, applied in the field of optical fiber parameter measuring instruments, can solve the problems of unfavorable measurement concentration and saving, inability to measure polymer fiber optics, single measurement parameters, etc., and achieve simple and easy measurement and calculation process, high The effect of high measurement accuracy, automation and system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

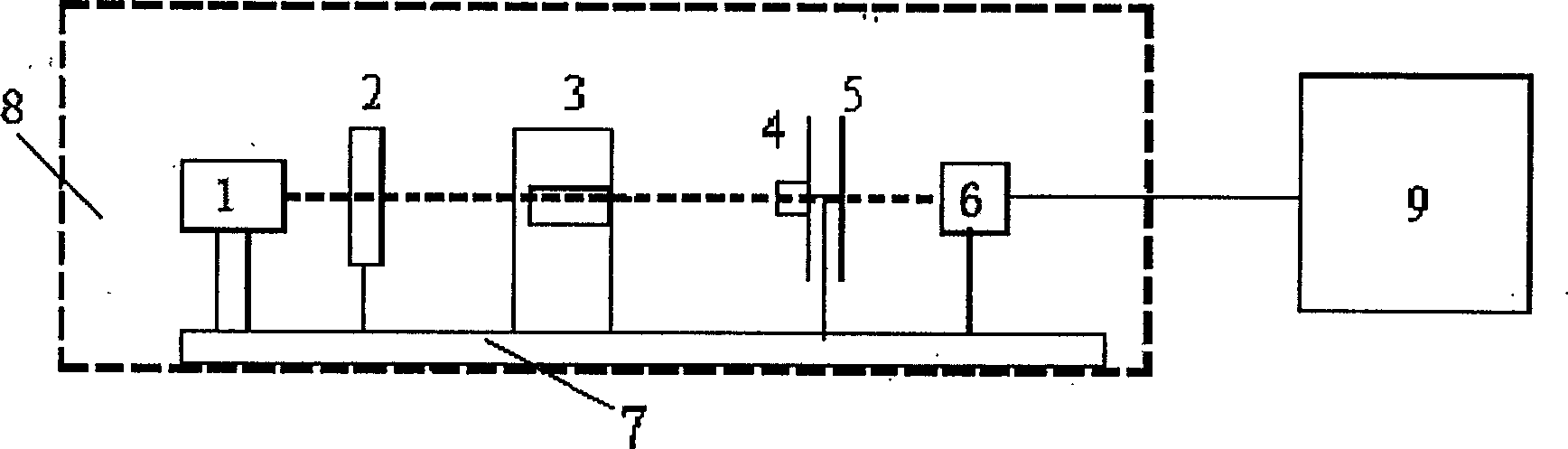

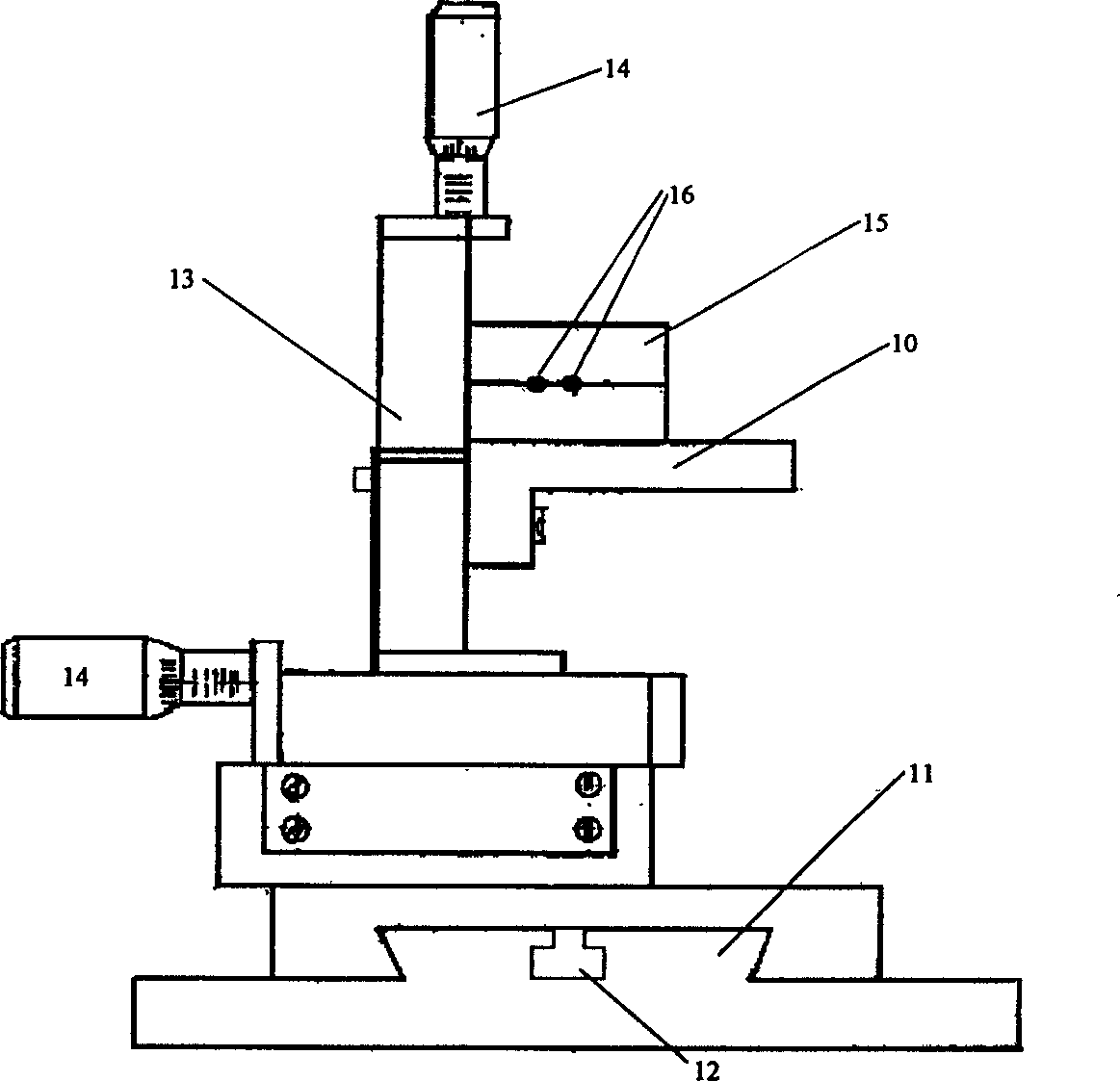

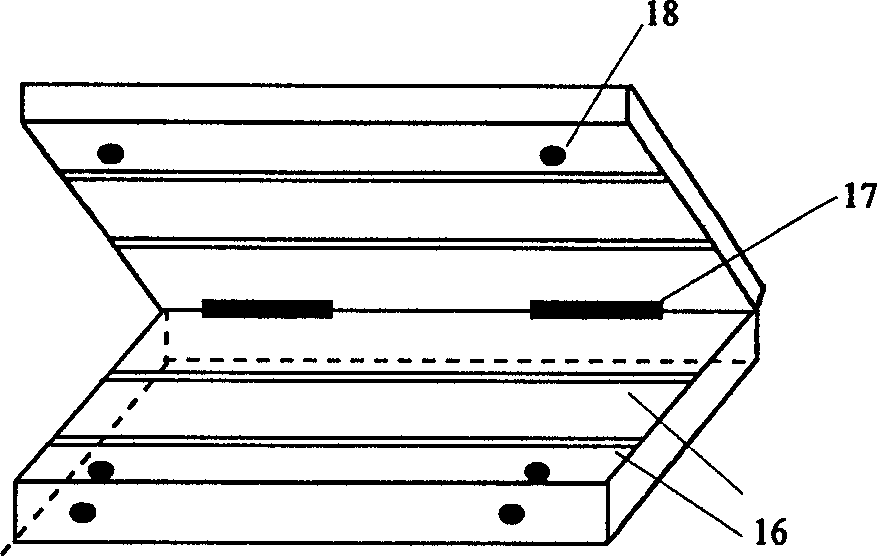

[0035] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0036] The lighting source is an ordinary Lambertian light source, and the continuously adjustable attenuator is composed of two polarizing filters (marumi P.L 55mm). The size of the optical fiber, the aperture of the diaphragm is 0.5mm, 0.8mm, 1.5mm, 2.0mm, 3.0mm, and it is a rotary adjustment. The light source, attenuator, microscope objective lens, aperture, CCD camera support and guide rail are for two-dimensional movement, the stage support and guide rail are for three-dimensional movement, and the thread trimmer set on the stage support It is also three-dimensional, and its adjustment range is ±3mm each. The fiber optic clamp is made of K9 glass with a length of 8 cm. The clamp is connected as a whole by a hinge 17. A pair of clamping grooves with a diameter of 1 mm are arranged on it. The end faces and clamping grooves are strictly polished, and the ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com