Novel optical polymer composite film and manufacturing method and application thereof

A composite thin film and optical thin film technology, applied in optics, optical components, instruments, etc., can solve the problems of unsuitable promotion conditions, expensive metal films and dielectric films, and restrictions on the application of optical thin films, so as to achieve large-scale production, Wide range of application scenarios and application range, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

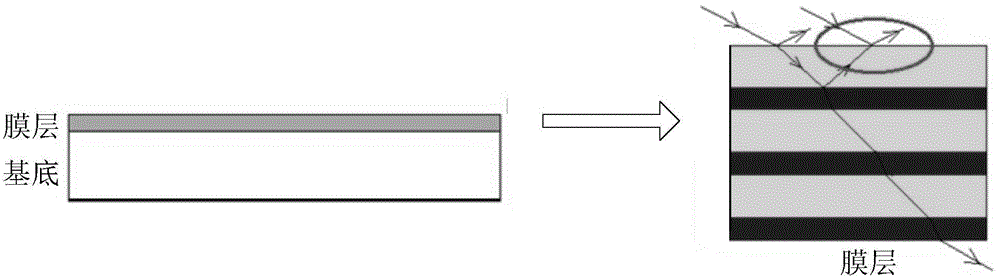

[0033] In the present invention, the optical thin film design principle of the optical coating is integrated into the traditional thin film manufacturing process, thereby proposing a novel optical polymer composite thin film and a manufacturing method thereof.

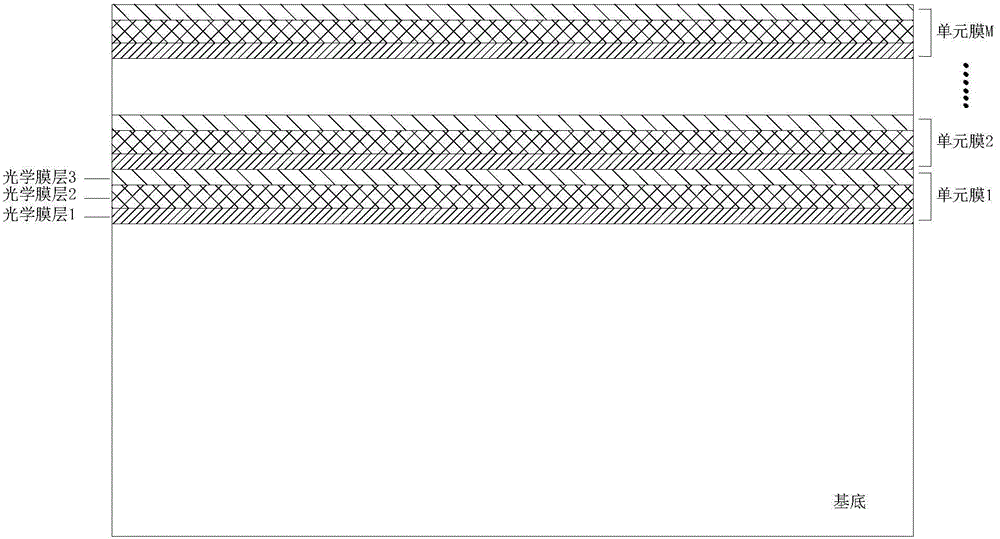

[0034] Such as figure 2 As shown, in a novel optical polymer composite film and its manufacturing method proposed by the embodiments of the present invention, it is made by covering the surface of the substrate with an optical film; wherein, the substrate is made of a polymer material, and the optical film is composed of M unit films Superposed, where M>2, each unit film is made of N layers of optical film layers made of polymer materials, where N=2 or N=3, each optical film layer has a predetermined film thickness, Any two adjacent optical film layers have different refractive indices.

[0035] In a specific embodiment, the surface of the substrate is covered with an optical film, and M unit films in the optical film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com