UV (Ultraviolet)-NIR (Near-Infrared) dual band absorbing optical filter and preparation method thereof

A near-infrared absorber and ultraviolet absorber technology, applied in optics, optical components, instruments, etc., can solve the problem of not being able to protect the laser at the same time, and achieve the effects of small chromatic aberration, good mechanical properties, and simple and fast preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

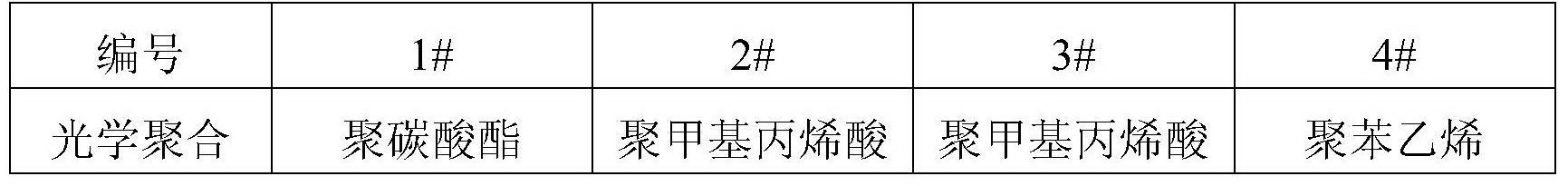

Embodiment 1

[0026] (1) Select polycarbonate as the optical polymer matrix material, 100 parts by mass, seal and dry at 120°C for 6 hours, and set aside;

[0027] (2) Absorbent component: benzotriazole UV-360 (molecular formula: C 41 h 50 N 6 o 2 ), 0.5 parts by mass; o-phenylenediamine cobalt complex dye (molecular formula: Co[C 6 h 4 -(NH) 2 ] 2 ), 0.03 parts by mass; thiodiene nickel complex dye (molecular formula: C 28 h 20 NeS 4 ), 0.04 parts by mass;

[0028] (3) Put the polycarbonate particles described in (1) and the three absorbent powders described in (2) into the mixing tank, set the barrel speed to 180r / min, and pre-mix for 60min;

[0029] (4) Take out the mixing tank, add 0.5g liquid paraffin, and mix for 3 hours to obtain dark green translucent masterbatch;

[0030] (5) Set the parameters of the injection molding machine according to the injection molding requirements of polycarbonate;

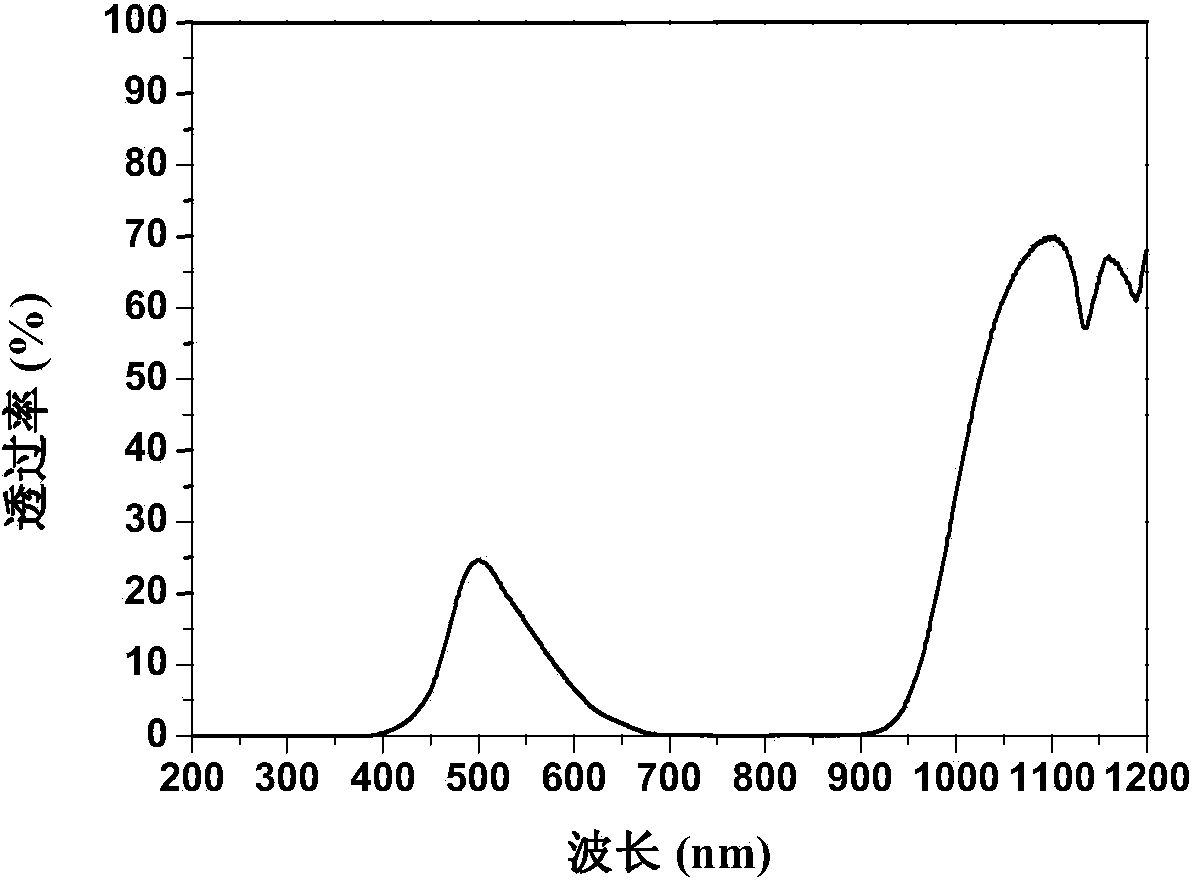

[0031] (6) Carry out injection molding of the color masterbatch prepared in (...

Embodiment 2

[0037] (1) Select polymethyl methacrylate as the optical polymer matrix material, 100 parts by mass, seal and dry at 80°C for 5 hours, and set aside;

[0038] (2) Absorbent component: benzotriazole UV-360 (molecular formula: C 41 h 50 N 6 o 2 ), 0.4 parts by mass; o-phenylenediamine cobalt complex dye (molecular formula: Co[C 6 h 4 -(NH) 2 ] 2), 0.02 parts by mass; antimony hexafluoride radical arylamine dye (molecular formula: C 62 h 92 N 6 .SbF 6 ), 0.03 parts by mass;

[0039] (3) Put the polymethyl methacrylate particles described in (1) and the three absorbent powders described in (2) into the mixing tank, set the barrel speed to 200r / min, premix 50min;

[0040] (4) Take out the mixing tank, add 0.4g liquid paraffin, and mix for 2.5 hours to obtain dark green translucent masterbatch;

[0041] (5) Set the parameters of the injection molding machine according to the injection molding requirements of polymethyl methacrylate;

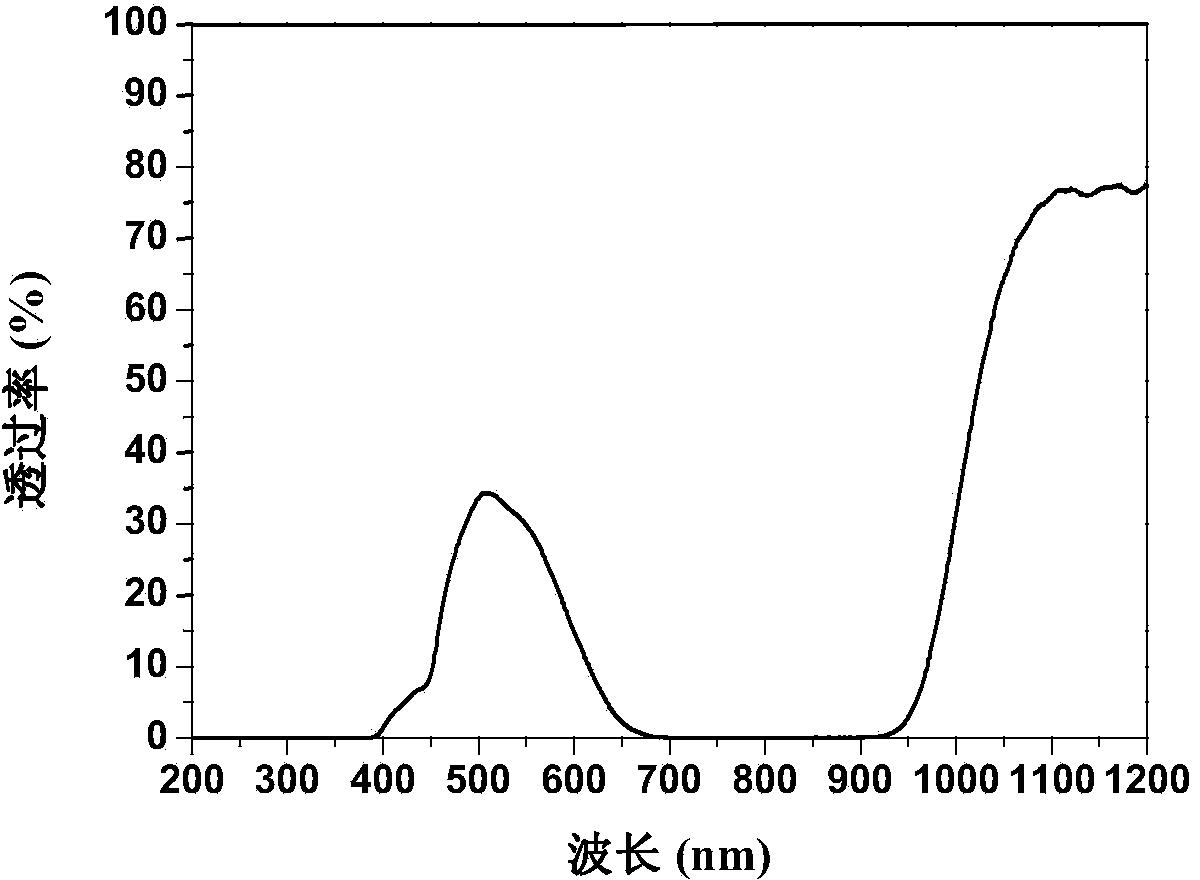

[0042] (6) Carry out injection mol...

Embodiment 3

[0048] (1) Select polymethyl methacrylate as the optical polymer matrix material, 100 parts by mass, seal and dry at 90°C for 4 hours, and set aside;

[0049] (2) Absorbent component: benzophenone UV-531 (molecular formula: C 21 h 26 o 3 ), 0.6 parts by mass; indole bromide polymethine cyanine dye (molecular formula: C 32 h 36 ClN 2 .Br), 0.02 parts by mass; thiodiene nickel complex dye (molecular formula: C 28 h 20 NeS 4 ), 0.03 parts by mass;

[0050] (3) Put the polymethyl methacrylate particles described in (1) and the three kinds of absorbent powders described in (2) into the mixing tank, set the barrel speed to 220r / min, premix 40min;

[0051] (4) Take out the mixing tank, add 0.3g liquid paraffin, and mix for 2.5 hours to obtain dark green translucent masterbatch;

[0052] (5) Set the parameters of the injection molding machine according to the injection molding requirements of polymethyl methacrylate;

[0053] (6) Carry out injection molding of the color mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com