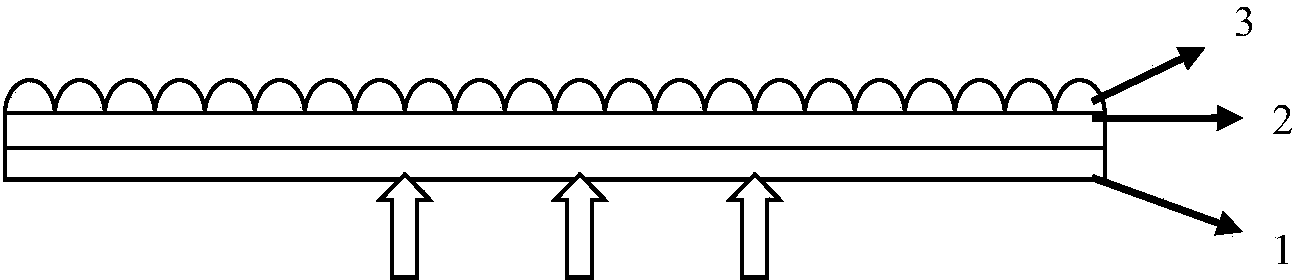

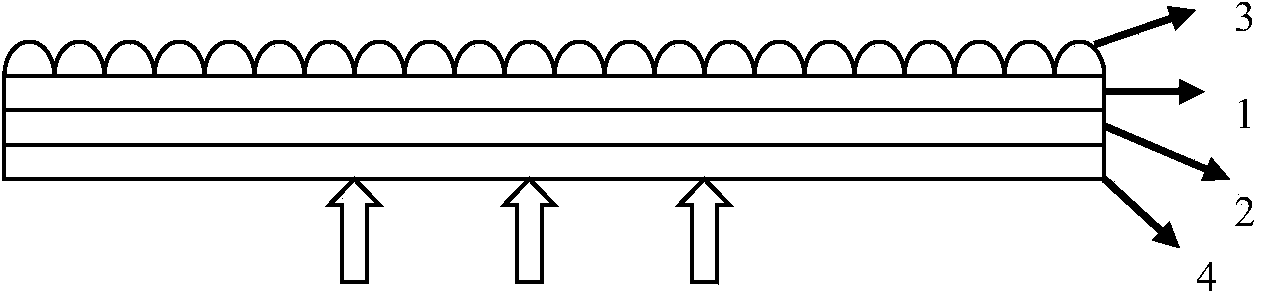

Light-emitting film used for LED lighting and provided with micro-mirror structure and preparing method thereof

A technology for LED lighting and light-emitting films, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as poor light-emitting performance, achieve stable light-emitting performance, good heat dissipation performance, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

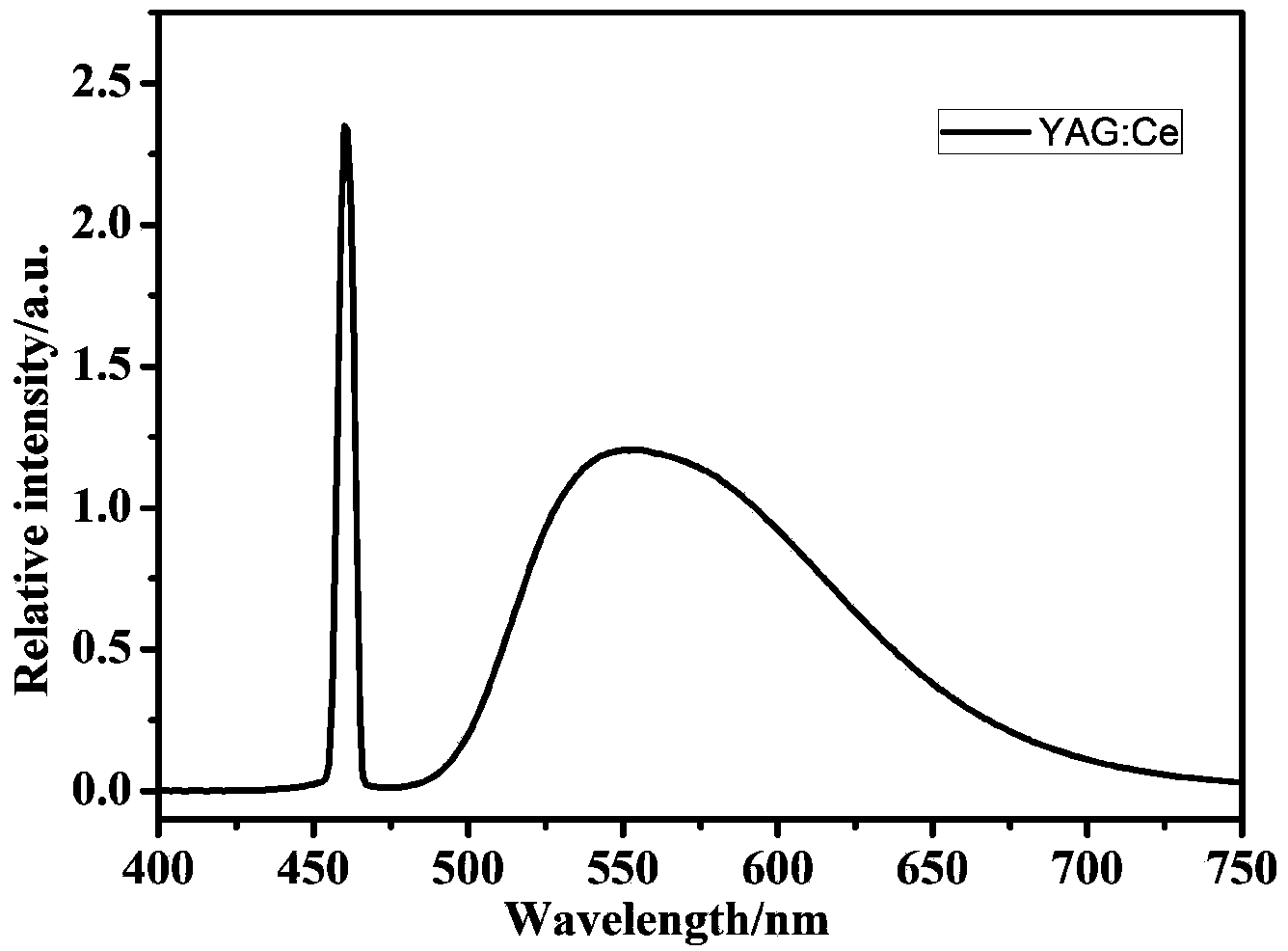

Embodiment 1

[0029] (1) Preparation of fluorescent slurry: choose aluminate yellow fluorescent powder with a particle size of 3-12um. Weigh raw materials according to mass ratio: phosphor 15%, binder (epoxy resin 60%, dimethyl silicone oil 20.0%), anti-settling agent (fumed silica) 2%, dispersant (dodecylsulfuric acid Sodium) 2.5%, defoamer (organosiloxane) 0.5%; add the liquid raw materials in the formula into the batching container, add phosphor powder under stirring, and stir evenly; add deionized water while stirring, adjust the slurry The viscosity coefficient is 400mPas, and the vacuum degassing treatment is carried out to obtain the fluorescent slurry; (2) the substrate PET, the substrate is ultrasonically cleaned, and dried in a vacuum drying oven at a drying temperature of 60°C and a drying time of 1- 2h; (3) Use the screen process to print fluorescent paste on the substrate PET, and dry it by infrared to prepare the phosphor coating; (4) Use PC resin film, the thickness of which ...

Embodiment 2

[0033](1) Prepare fluorescent slurry: choose aluminate yellow phosphor, add appropriate amount of nitride red phosphor, particle size is 3-12um, weigh raw materials according to mass ratio: yellow phosphor 12%, red phosphor 3%, Adhesive (polyurethane 60%, terpineol 10%, simethicone 10.0%), anti-settling agent (fumed silica) 2%, dispersant (sodium lauryl sulfate) 2.5%, disinfectant Foaming agent (organosiloxane) 0.5%; add the liquid raw materials in the formula into the batching container, add phosphor powder under stirring, and stir evenly; add deionized water while stirring, adjust the viscosity coefficient of the slurry to 500mPas, and Perform vacuum defoaming treatment to obtain fluorescent slurry; (2) The substrate is PET, and the substrate is ultrasonically cleaned and dried in a vacuum drying oven at a drying temperature of 60°C and a drying time of 1-2 hours; (3) Use the screen printing process to print the fluorescent paste on the PET substrate, dry it by infrared, pre...

Embodiment 3

[0035] (1) Preparation of fluorescent slurry: choose silicate yellow fluorescent powder with a particle size of 3-12um, and weigh the raw materials according to the mass ratio: 30% fluorescent powder, 15% adhesive (50% acrylate, ethyl silicone oil), Anti-sedimentation agent (fumed silica) 2%, dispersant (polyvinyl alcohol) 2.5%, defoamer (organosiloxane) 0.5%; add the liquid raw materials in the formula to the batching container, and add it under stirring Fluorescent powder, stir evenly; add deionized water during stirring, adjust the viscosity coefficient of the slurry to 300mPas, and perform vacuum degassing treatment to obtain fluorescent slurry; (2) The substrate is plexiglass (PMMA) film, and the base The materials were ultrasonically cleaned and dried in a vacuum drying oven at a drying temperature of 60°C and a drying time of 1-2 hours; (3) Printed fluorescent paste on the plexiglass film using a screen printing process, and dried it by infrared. Phosphor powder coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com