Method for preparing porous ceramic filter membrane by low-temperature sintering

A technology of porous ceramics and low-temperature sintering, applied in the field of ceramic materials, can solve the problems of contradicting low consumption, green, environmental protection and sustainable development, increasing the production cost of ceramic filter membranes, and being difficult to realize industrialized production, etc., and achieve a complete membrane thickness. , The effect of reducing energy consumption and easy availability of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

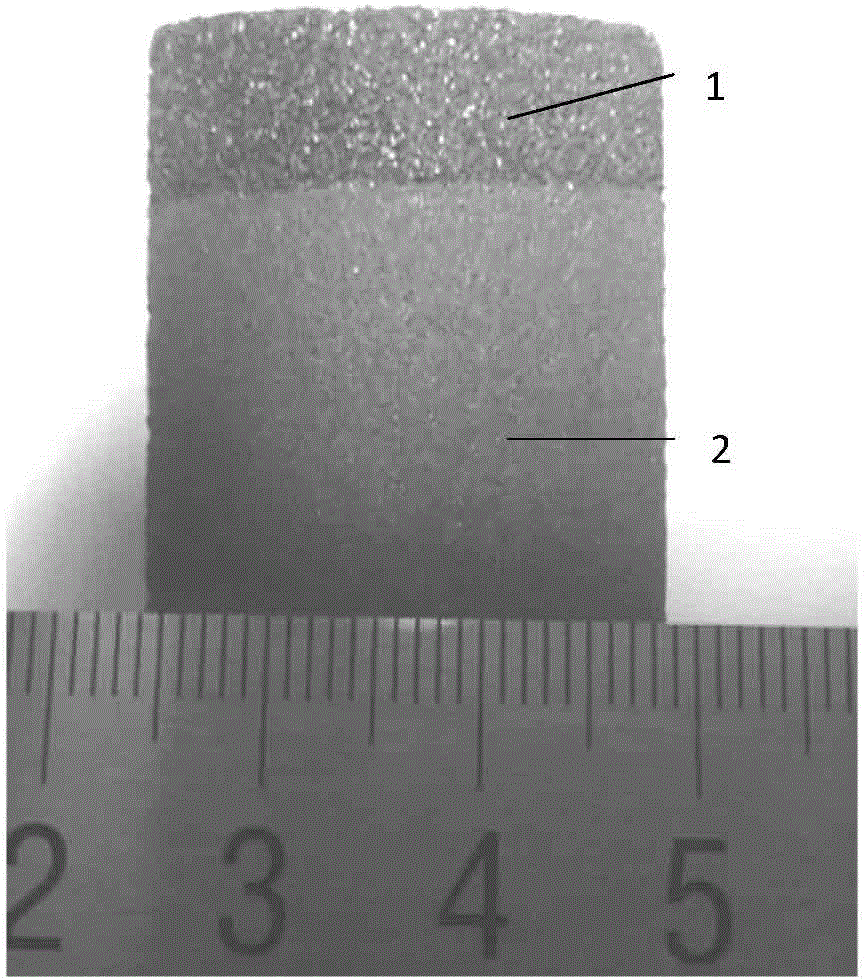

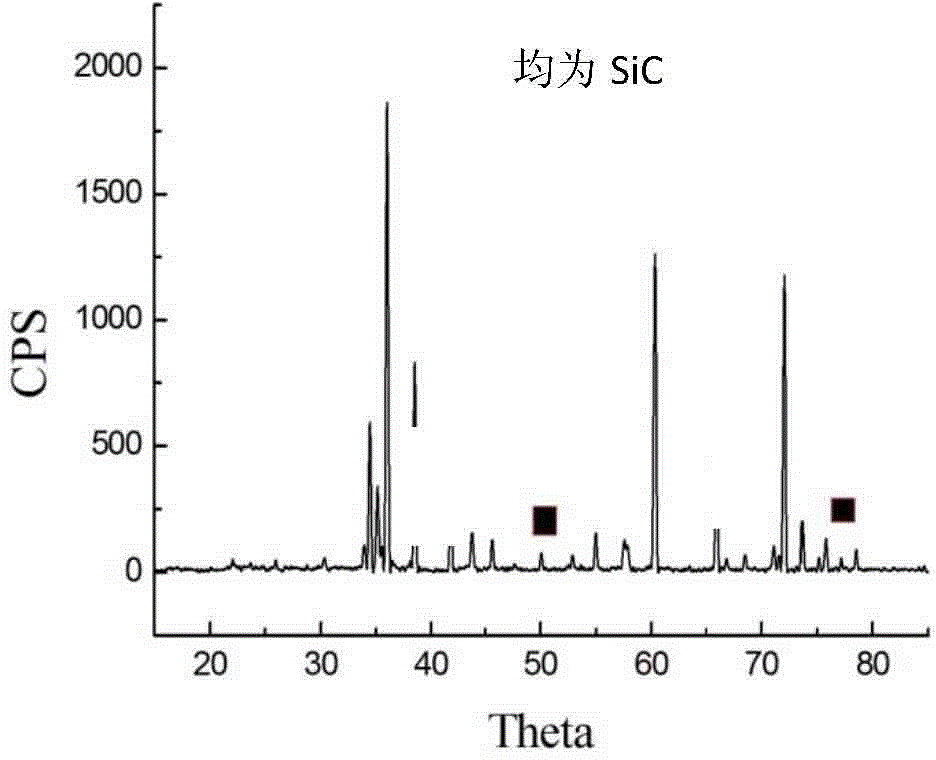

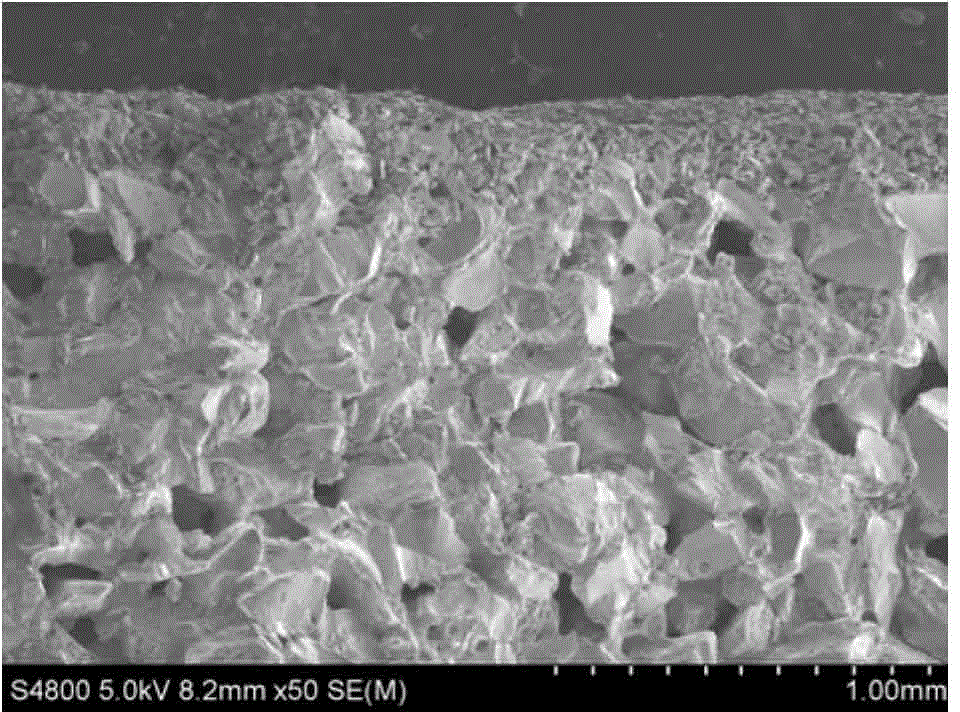

Embodiment 1

[0038] 1) Excellent sintering aid: Put the glass phase, silica powder, feldspar and clay in a nylon tank at a mass ratio of 50:30:5:15 to form a mixture, and then add 40% of the total volume of the mixture to it Anhydrous ethanol as a solvent, mixed on a ball mill for 12 hours with alumina ceramic balls, dried, and passed through a 500-mesh sieve to obtain a sintering aid; wherein, the total volume of the added solvent anhydrous ethanol and the mixture is the same as that of the alumina The volume ratio of the ceramic grinding ball is 1:1.5; the filling ratio of the mixture in the nylon tank is 30%;

[0039] 2) In terms of parts by mass, add 43.9 parts of industrial grade black silicon carbide particles W40 and 6 parts of sintering aid to 50 parts of deionized water in batches by mechanical stirring; after 5 minutes, accurately weigh 1 part of carboxyl Add sodium methylcellulose in batches, then continue to stir for 20 minutes until sodium carboxymethylcellulose dissolves comp...

Embodiment 2

[0045] 1) Excellent sintering aid: Put the glass phase, silica powder, feldspar and clay in a nylon tank at a mass ratio of 40:20:10:30 to form a mixture, and then add 20% of the total volume of the mixture to it Solvent absolute ethanol, use silicon carbide ceramic balls to mix on a ball mill for 24 hours and dry, pass through a 500 mesh sieve to obtain a sintering aid; the added solvent absolute ethanol and the total volume of the mixture are the same The volume ratio of the ball is 1:1; the filling ratio of the mixture in the nylon tank is 40%;

[0046] 2) In terms of parts by mass, add 42 parts of industrial grade black silicon carbide particles W40 and 6 parts of sintering aid to 50 parts of deionized water in batches by mechanical stirring; after 5 minutes, accurately weigh 1.5 parts of carboxyl Sodium methylcellulose was added therein in batches, and then continued to stir for 20 minutes until the sodium carboxymethylcellulose was completely dissolved; then 0.5 parts of...

Embodiment 3

[0053] 1) Excellent sintering aid: Put glass phase, silica, feldspar and clay in a nylon tank at a mass ratio of 43:25:7:25 to form a mixture, and then add 40% of the total volume of the mixture to it The solvent absolute ethanol is mixed with alumina ceramic balls on a ball mill for 24 hours, dried, and passed through a 500-mesh sieve to obtain a sintering aid; the added solvent absolute ethanol and the total volume of the mixture are equal to The volume ratio of the ball is 1:1; the filling ratio of the mixture in the nylon tank is 50%;

[0054] 2) In terms of parts by mass, add 52.3 parts of industrial grade black silicon carbide particles W40 and 5 parts of sintering aid to 40 parts of deionized water in batches by mechanical stirring; after 5 minutes, accurately weigh 1 part of carboxyl Sodium methylcellulose and 1 part of polyvinyl alcohol were added in batches, and then continued to stir for 40 minutes until sodium carboxymethylcellulose and polyvinyl alcohol were compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com