Gelatinization material of phosphoaluminic salt system

A cementitious material, phosphoaluminate technology, applied in the field of inorganic material science, can solve the problems of shortage of high-strength cement, the output of special cement can not meet the needs of special projects, etc., to achieve excellent durability, excellent performance, low firing temperature and other problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

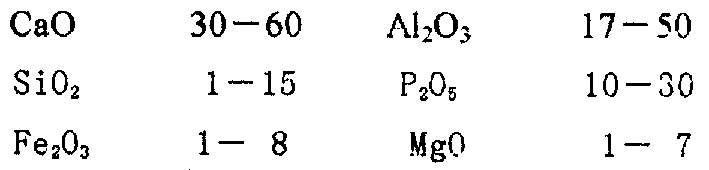

[0067] The suitable minerals limestone, apatite and bauxite are selected. Mix and homogenize according to the required chemical composition, after grinding, calcined at a high temperature of 1350-1400°C, grind the clinker obtained from the firing into fine powder, mix it with water, and add water to control the fluidity of the slurry 118±2mm is suitable. The main chemical composition of its raw materials is shown in Table 5. The chemical compositions of raw meal and clinker are shown in Table 6 and Table 7. The strength of the aluminophosphate cement mortar specimens is shown in Table 8.

[0068] The main chemical composition of table 5 raw material (w / %)

[0069] mineral

[0070] L.O.I.SiO 2 Al 2 o 3 Fe 2 o 3 CaO MgO P 2 o 5

[0071] 14.41 12.87 66.05 0.90 0.67 0.12

[0072] alum

[0073] 15.41 2.46 72.18 1.08 3.03 1.58

[0074] earth

[0075] 14.10 21.22 52.32 8.28 3.11 0.79

[0076] Stone 42.28 4.09 0.20 0.22 45.27 3.75

...

Embodiment 2

[0083] The production process and raw material composition as described in Example 1, the strength of the raw meal, clinker and cement mortar specimens of the aluminophosphate cement are shown in Table 6, Table 7 and Table 8.

[0084] Table 6. Chemical Composition of Raw Meal (w / %)

[0085] L.O.I.SiO 2 Al 2 o 3 Fe 2 o 3 CaO MgO P 2 o 5

example 1

[0086] Example 1 20.36 5.20 37.44 1.42 24.34 2.41 8.27

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com