Modified portland cement clinker and preparation method thereof

A Portland cement and cement clinker technology, applied in cement production and other directions, can solve the problems of limited application scope and scale, low comprehensive utilization rate, waste of land resources, etc. Fast hydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

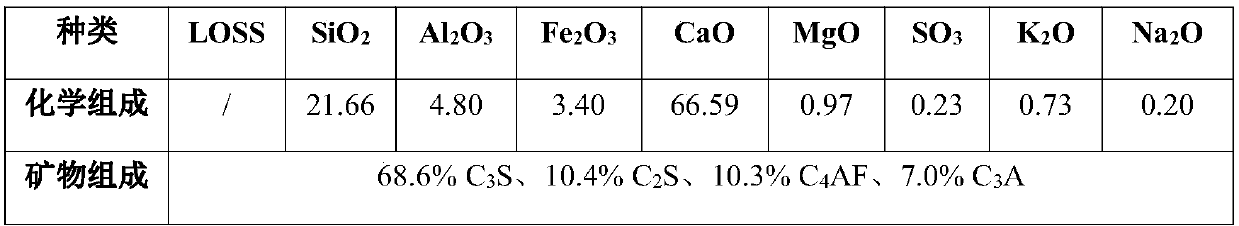

Embodiment 1

[0025] Using the preparation method of modified Portland cement clinker, the test was carried out in the new dry method precalcining kiln of Gezhouba Jingmen Cement Co., Ltd. The specific operation steps are as follows:

[0026] (1) Limestone is crushed to a 70mm square hole sieve residue <10%, pre-homogenized and stored in the limestone shed, shale, kaolin, sulfuric acid slag and other raw materials are homogenized and stored in the joint storage.

[0027] (2) Mix 82% limestone, 8% shale, 8% kaolin and 2% iron powder evenly according to the ratio of mass fraction, among which control limestone CaO is 51-52%, shale SiO 2 68-70%, kaolin Al 2 o 3 16-20%, sulfuric acid slag Fe 2 o 3 65-70%.

[0028] (3) Send the above mixed material into the vertical mill for drying and grinding, screen the finished product with moisture content≤1.0wt% and 20mm square hole sieve ≤2.0wt% as cement raw meal, and send it into raw meal Chemical library storage.

[0029] (4) Feed the homogenized...

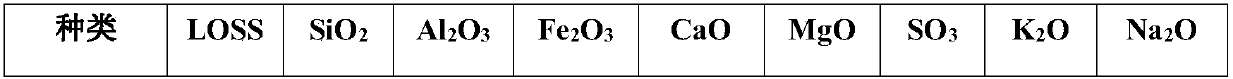

Embodiment 2

[0039] Using the preparation method of modified Portland cement clinker, the test was carried out in the new dry method precalcining kiln of Gezhouba Jingmen Cement Co., Ltd. The specific operation steps are as follows:

[0040] (1) Limestone is crushed to 70mm square hole sieve residue <10%, pre-homogenized and stored in limestone shed, shale, kaolin, sulfuric acid slag, phosphogypsum and other raw materials are homogenized and stored in joint storage.

[0041] (2) Mix 78% limestone, 10% shale, 8% kaolin, 1% iron powder and 3% phosphogypsum according to the proportion of mass fraction, among which control limestone CaO is 51-52%, shale SiO 2 68-70%, kaolin Al 2 o 3 16-20%, sulfuric acid slag Fe 2 o 3 65-70%, phosphogypsum SO 3 35-42%.

[0042] (3) Send the above mixed material into the vertical mill for drying and grinding, screen the finished product with moisture content≤1.0wt% and 20mm square hole sieve ≤2.0wt% as cement raw meal, and send it into raw meal Chemical l...

Embodiment 3

[0055] Using the preparation method of modified Portland cement clinker, the test was carried out in the new dry method precalcining kiln of Gezhouba Jingmen Cement Co., Ltd. The specific operation steps are as follows:

[0056] (1) Limestone is crushed to 70mm square hole sieve residue <10%, pre-homogenized and stored in limestone shed, shale, kaolin, sulfuric acid slag, phosphogypsum and other raw materials are homogenized and stored in joint storage.

[0057] (2) Mix 75% limestone, 8% shale, 10% kaolin, 2% iron powder and 5% desulfurized gypsum according to the proportion of mass fraction, among which control limestone CaO is 51-52%, shale SiO 2 68-70%, kaolin Al 2 o 3 16-20%, sulfuric acid slag Fe 2 o 3 65-70%, phosphogypsum SO 3 40-45%.

[0058] (3) Send the above mixed material into the vertical mill for drying and grinding, screen the finished product with moisture content≤1.0wt% and 20mm square hole sieve ≤2.0wt% as cement raw meal, and send it into raw meal Chem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com