Method for fabricating coupling shear specimen containing natural structure surface

A technology of natural structure and manufacturing method, applied in the preparation of test samples, etc., can solve the problems of inability to ensure that the sample with the structure surface is completely consistent, cannot realize the complete coupling of the upper plate and the lower plate, and cannot reliably ensure the complete coupling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

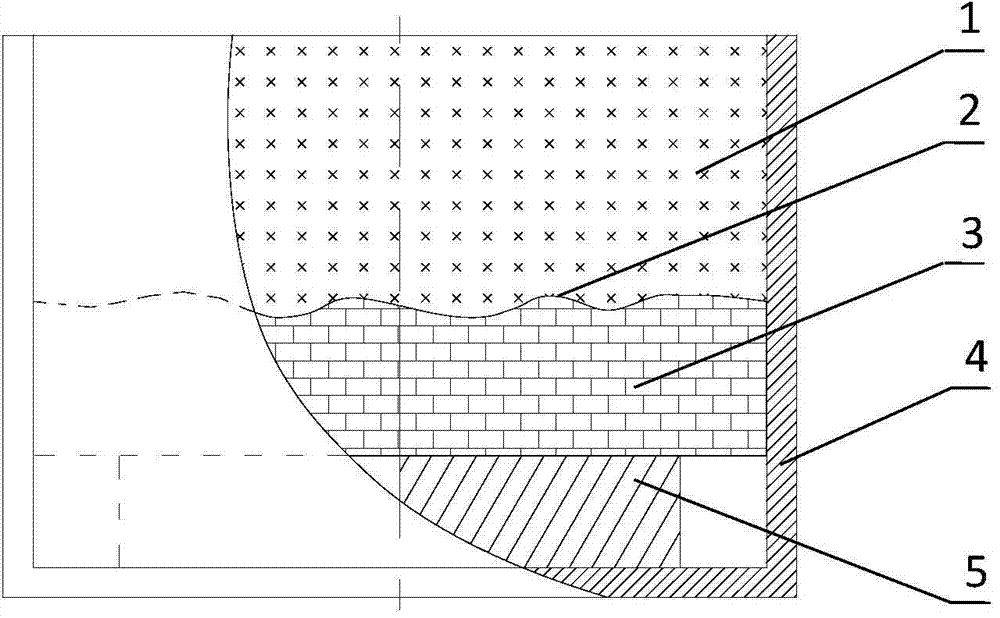

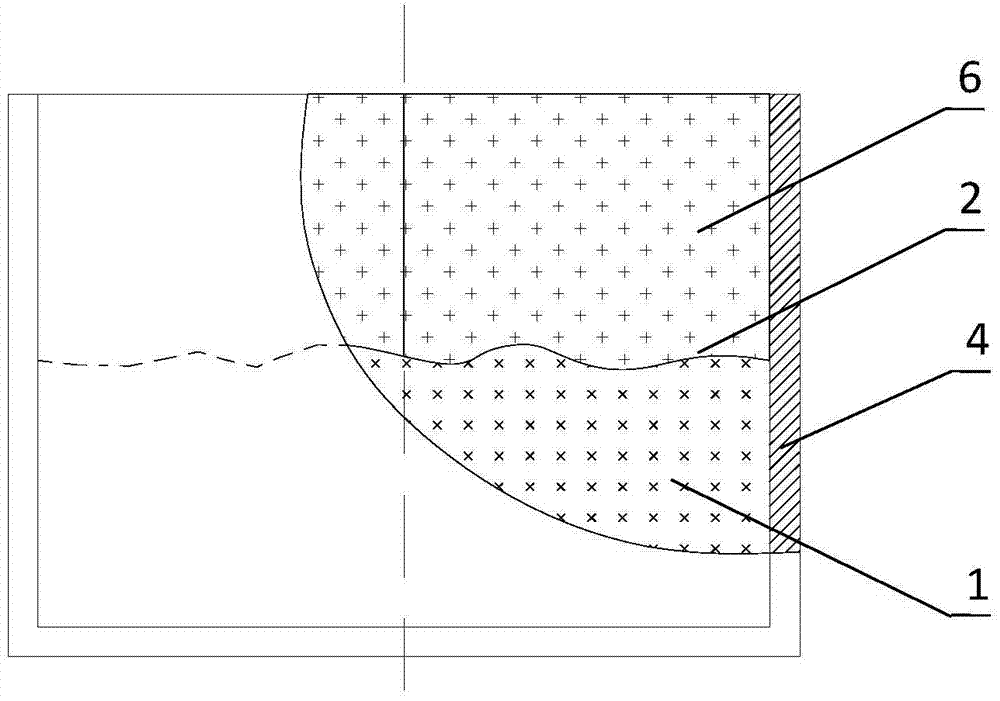

[0055] In order to carry out the shear test on the standard specimen (a cube with a side length of 15.0cm) containing the natural structural plane 2 on the RMT rock direct shear specimen machine, a batch of coupled shear specimens containing the natural structural plane 2 are now prepared, and the specific implementation Methods as below:

[0056] (1) Scan the natural structural surface of the rock mass: select a rough natural structural surface of the rock mass from the project site, and the length of the rock mass structural surface in each direction reaches about 20.0cm. After cleaning the surface to remove debris, Spray a thin layer of surface contrast enhancer to achieve the effect of enhancing the contrast of the natural structural surface of the rock mass. After the contrast enhancer dries, randomly paste the surface of the natural structural surface of the rock mass with a distance of 6 cm and a diameter of 3.0 mm. Turn on the calibrated white light scanning instrument...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com