Oil well drilling geological X-ray fluorescent debris logging method

An oil drilling and X-ray technology, applied in wellbore/well components, earthwork drilling, etc., can solve the problems of expensive instruments, long analysis cycle, strict sample and environmental requirements, etc., to reduce detection costs and shorten analysis. Cycle, the effect of cheap instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

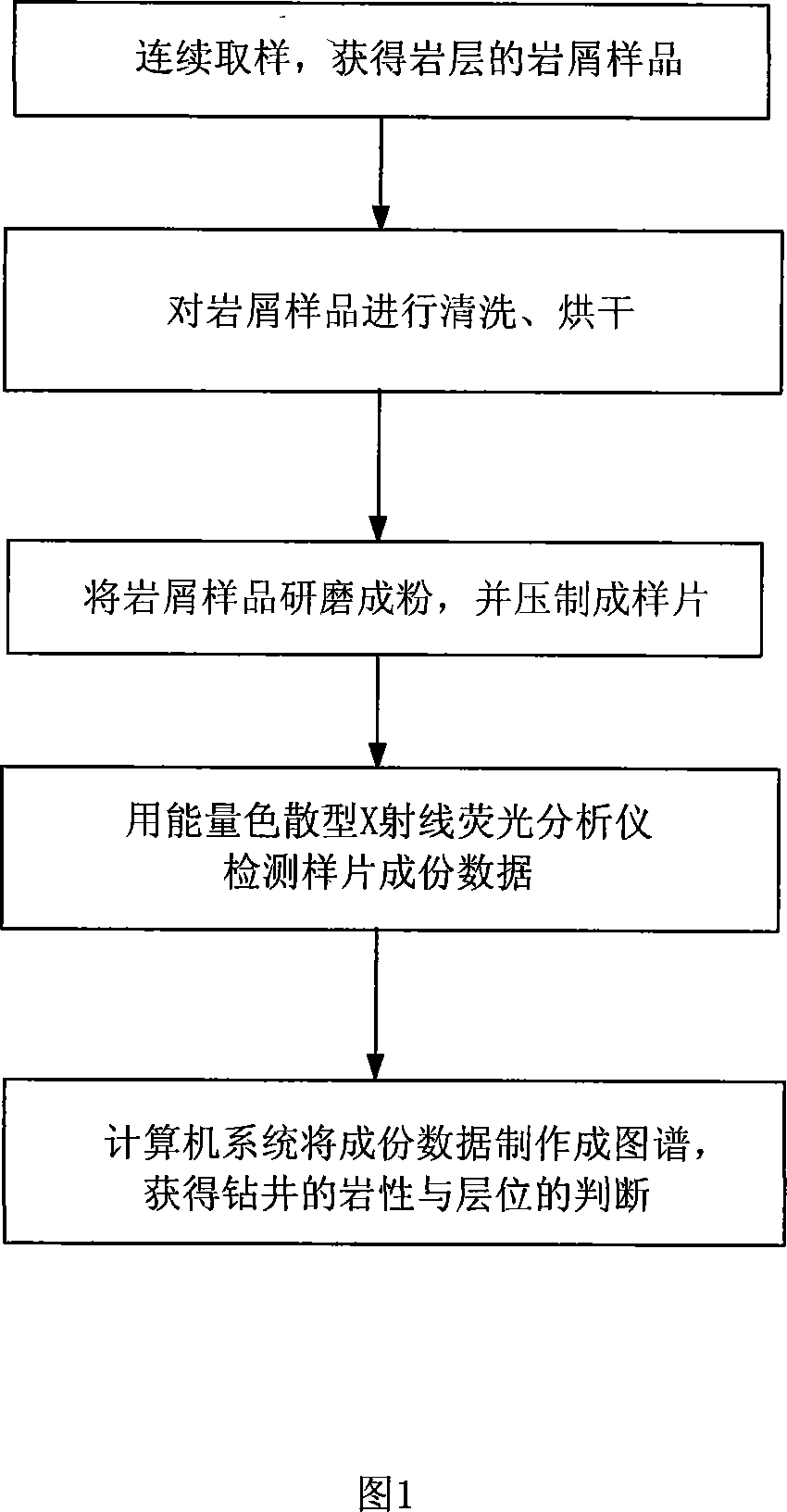

[0028] As shown in Figure 1:

[0029] A petroleum drilling geological X-ray fluorescence cuttings logging method, comprising the following steps:

[0030] Step 1: Continuously sample from shallow to deep according to the drilling depth to obtain cuttings samples of rock formations at each drilling depth; for every 1 meter of drilling, one cuttings sample is extracted.

[0031] Step 2, according to the drilling depth, clean the cuttings samples of each rock formation with clean water, and then dry the cuttings samples;

[0032] It only needs to be washed with clean water, and rapid detection can be carried out at room temperature, which reduces the detection cost.

[0033] Step 3: Grinding the rock chip samples of each rock formation into powder respectively, loading the sample powder into an extrusion die, and pressing the powder in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com