Rock structural surface shear test method and implementation apparatus thereof

A shear test, structural plane technology, applied in the direction of using a stable shear force to test the strength of materials, etc., can solve the problems of test failure, troubled rock structural plane shear test, structural plane damage, etc., and achieve reliable measurement results. Ease of measurement, the effect of promoting progress and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

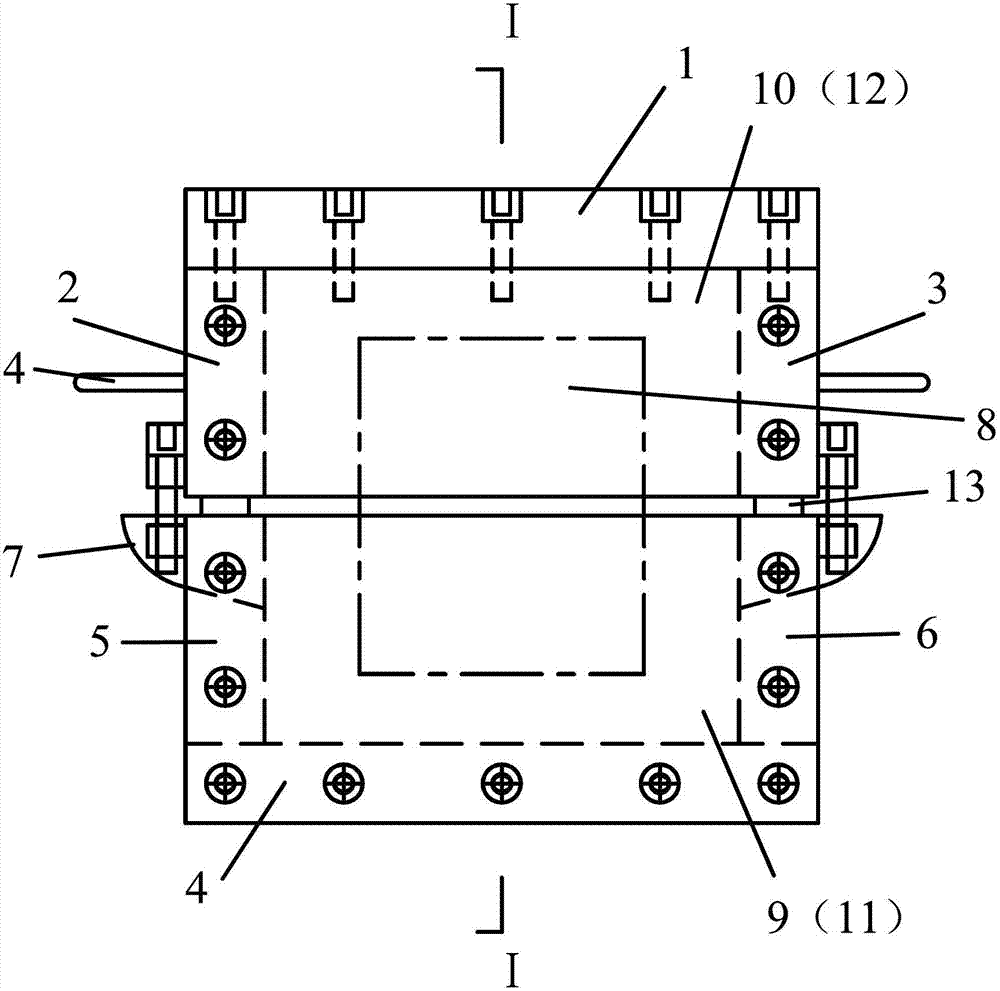

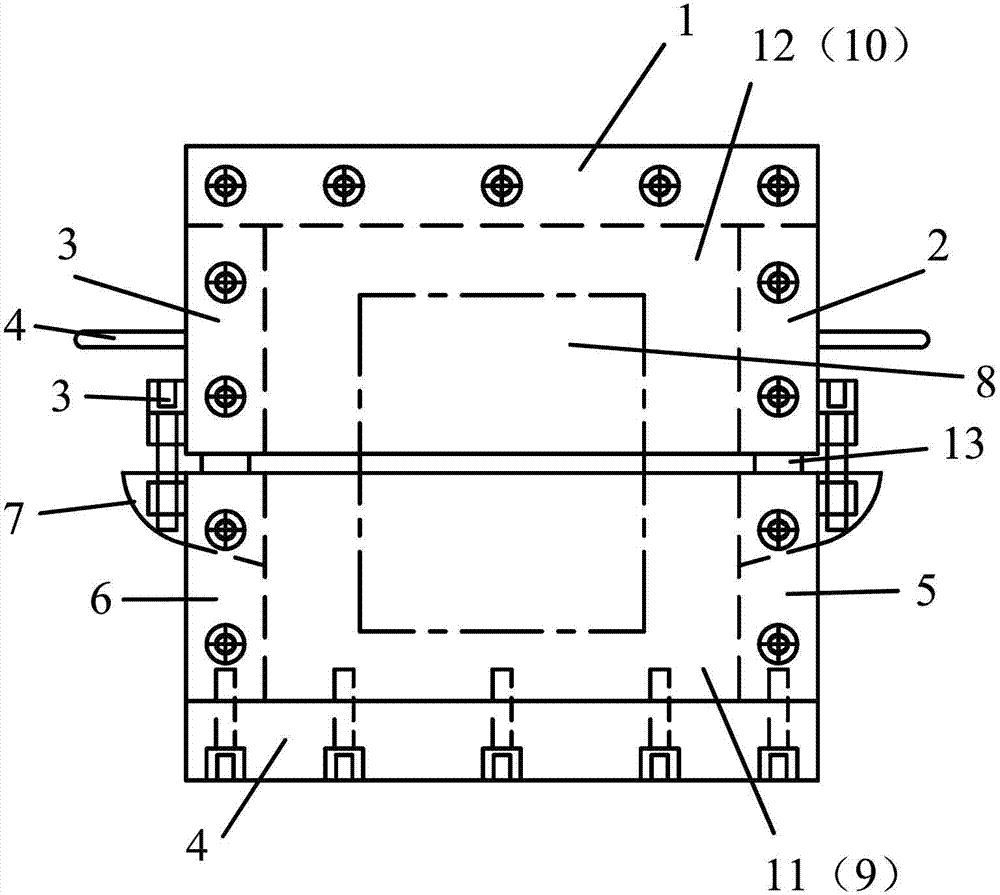

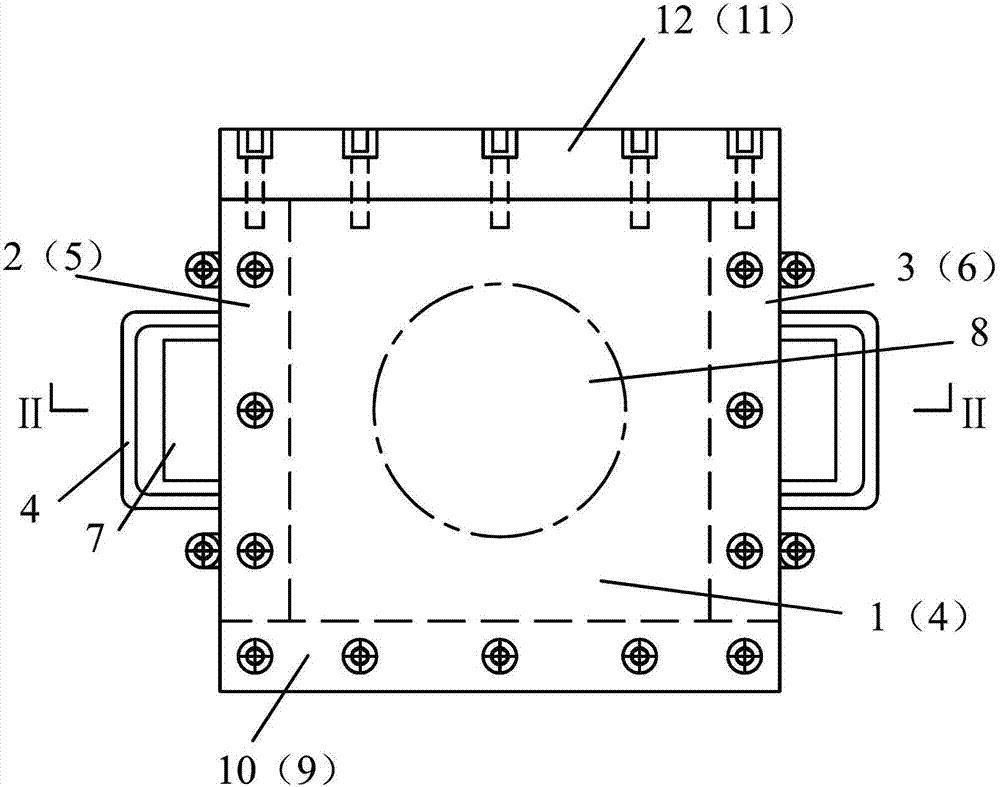

[0033] The structure of the rock structural surface shear test device of this embodiment is as follows: figure 1 to attach Figure 6 As shown, it consists of two upper and lower opening shear boxes matching the upper and lower parts of the rock sample test block 8. The upper and lower opening shear boxes are all combined structures, and are fixed and assembled by five box body plates through countersunk bolts. Integral, the box body plate surface on the side where the shear force is applied is crimped to the end surface of the box body plate in the other direction. The box body plate on which the upper shear box applies shear force is the rear side box body plate 12 , and the box body plate on which the lower shear box applies shear force is the front side box body plate 9 . The upper top box body plate 1 of the upper shear box is crimped to the box body plate end faces in the other three directions, and the lower bottom box body plate 4 of the lower shear box is crimped to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com