A reticle y-direction positioning device and method and a reticle transfer system

The technology of a positioning device and a transmission system is applied to the exposure device of the photoplate making process, the photoplate making process of the pattern surface, the microlithography exposure equipment, etc., and can solve the problems of easy damage and large force when positioning the reticle. To achieve the effect of protection from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

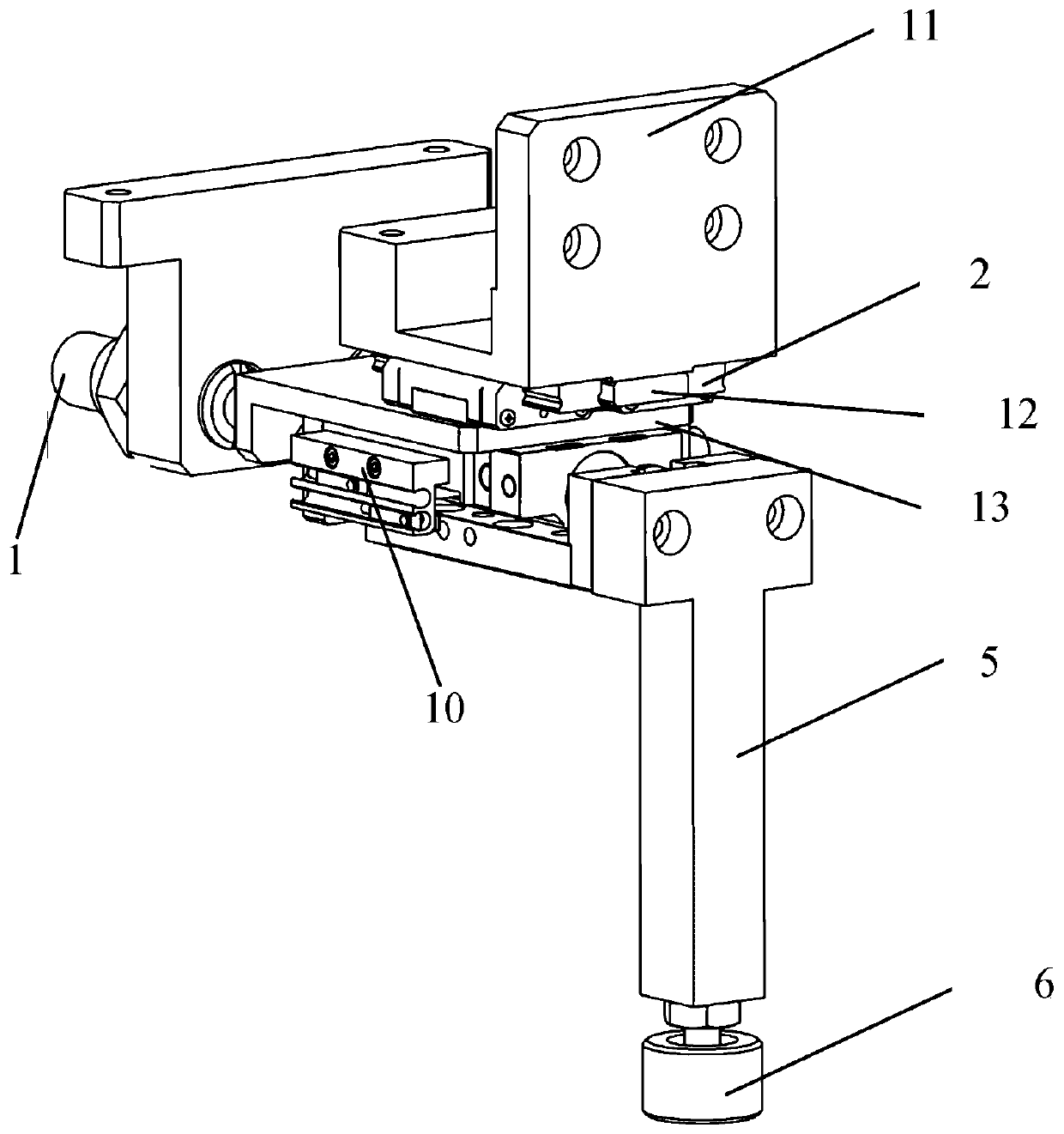

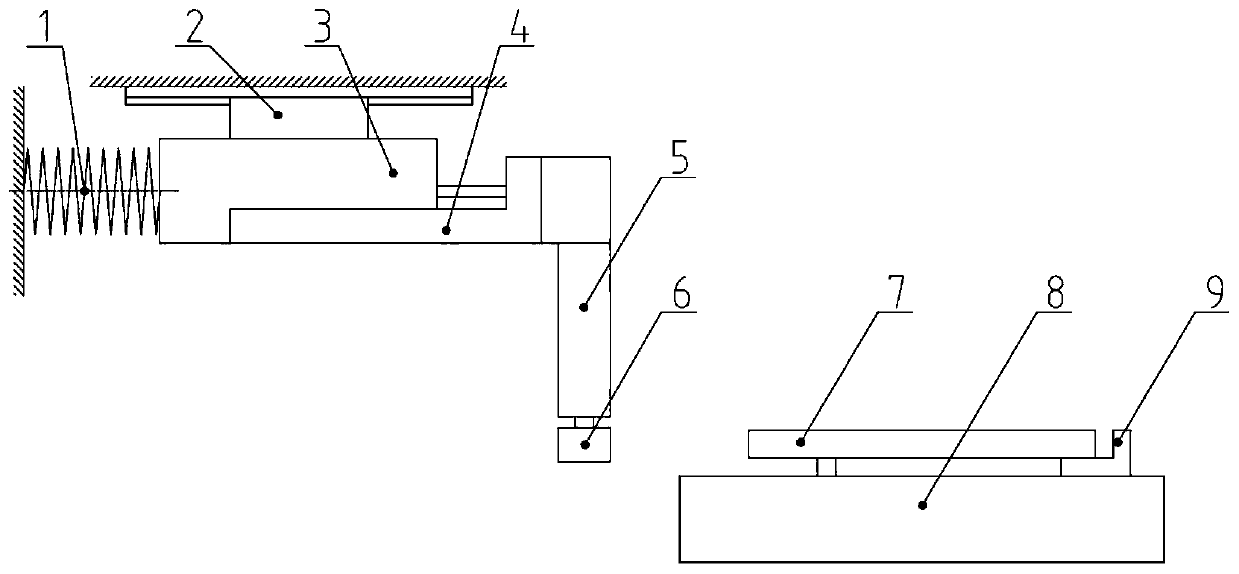

[0036] figure 1 It is a three-dimensional structural diagram of the reticle Y-direction positioning device in Embodiment 1 of the present invention. Please refer to figure 1 , this embodiment 1 provides a reticle Y-direction positioning device, including an over-position protection structure and a push rod structure, and the over-position protection structure pushes the push rod structure to move in the direction where the reticle is located and absorbs excess force on the reticle .

[0037] Specifically, the over-position protection structure includes: an elastic component 1 , a guide rail slider 2 and a driving element 10 , one end of the driving element 10 is connected to the elastic component 1 , and the other end is connected to the guide rail slider 2 . Further, in this embodiment, the elastic assembly 1 may be a spring assembly, and the driving element 10 may be an air cylinder, that is, one end of the spring assembly is connected to the air cylinder, and one end of t...

Embodiment 2

[0043] The main difference between embodiment 2 and embodiment 1 is that in embodiment 2, the spring assembly in embodiment 1 is replaced by a rubber assembly, and the position and connection relationship of each element remain unchanged.

[0044] Please continue to refer figure 1 , Embodiment 2 provides a Y-direction positioning device for a reticle, including an over-position protection structure and a push rod structure, and the over-position protection structure pushes the push rod structure to move toward the direction of the reticle and absorbs excess force on the reticle.

[0045]Specifically, the over-position protection structure includes: an elastic component 1 , a guide rail slider 2 and a driving element 10 , one end of the driving element 10 is connected to the elastic component 1 , and the other end is connected to the guide rail slider 2 . Further, in this embodiment, the elastic component 1 may be a rubber component, and the driving element 10 may be an air cyl...

Embodiment 3

[0050] The main difference between embodiment 3 and embodiment 1 is that the electric cylinder is used to replace the air cylinder in embodiment 1 in embodiment 3, and the position and connection relationship of each component remain unchanged.

[0051] Please continue to refer figure 1 , Embodiment 3 provides a Y-direction positioning device for a reticle, including an over-position protection structure and a push rod structure, and the over-position protection structure pushes the push rod structure to move toward the direction of the reticle and absorbs excess force on the reticle.

[0052] Specifically, the over-position protection structure includes: an elastic component 1 , a guide rail slider 2 and a driving element 10 , one end of the driving element 10 is connected to the elastic component 1 , and the other end is connected to the guide rail slider 2 . Further, in this embodiment, the elastic component 1 can be a spring component, and the driving element 10 can be an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com