Method for efficiently preparing stachyose from stachys sieboldii

A technology of stachyose and caddis, which is applied in the field of high-efficiency preparation of functional oligosaccharides, can solve the problems of insufficient utilization of waste liquid, limited production efficiency, and high production costs, so as to reduce salt pollution and improve Quality, the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

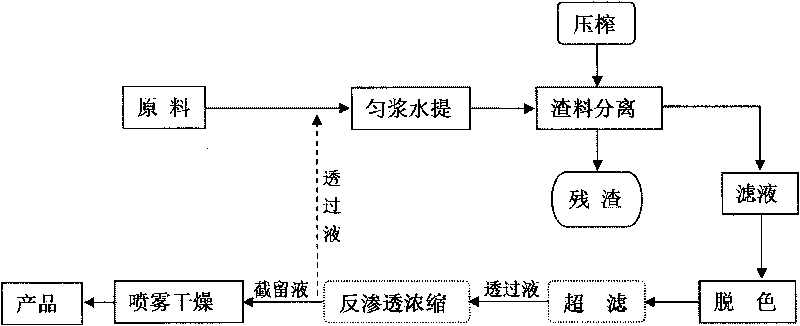

Method used

Image

Examples

Embodiment 1

[0015] Take 3 parts of fresh caddis silkworm, 100 kg each, and add 1000 kg of deionized water according to the ratio of material to liquid (w / v) 1:10, and compare the extraction rates of different extraction methods.

[0016] (1) Homogenization extraction method: the temperature is room temperature, the rotation speed is 30000rpm, and the homogenization time is 10min;

[0017] (2) Enzymatic hydrolysis method: the ratio of enzyme solution is 1.0% cellulase, 1.0% pectinase, 0.8% protease, the pH value of enzymolysis is 5.5, the enzymolysis time is 100min, and the enzymolysis temperature is 45°C;

[0018] (3) Blank control group: extract at 45°C for 100 minutes;

[0019] The extracts obtained by the above three extraction methods were sampled respectively, and the stachyose content was determined by HPLC-RID method, and the extraction rates of the three methods were 83%, 76%, and 45%, respectively.

[0020] It can be seen from Example 1 that the homogenate extraction method has ...

Embodiment 2

[0022] (1) Extraction of stachyose from homogenate: Take 100 kg of fresh caddis silkworm, add 500 kg of deionized water according to the ratio of material to liquid (w / v) 1:5, and homogenate for 15 minutes at a temperature of 30°C and a speed of 22,000 rpm. Efficient extraction of stachyose, the homogenate sample was detected by HPLC-RID method, and the extraction rate of stachyose reached 82%;

[0023] (2) Filtration: Slag material is separated by cloth bag filtration. Filtration area 5m 2 , filter pore size 5um, filter pressure 0.5Mpa, water flow rate 5T / h, 537 kg of filtrate was obtained after the extract was separated from slag.

[0024] (3) Macroporous resin decolorization: at normal temperature, pass the filtrate through a chromatographic column equipped with macroporous adsorbent resin at a flow rate of 2 column bed volumes / hour for decolorization, and stop loading when the processing capacity is 3 times the column bed volume , with 2 times of column bed volume top wa...

Embodiment 3

[0027] (1) Homogenate to extract stachyose: take 100 kg of fresh caddis silkworm, add 1500 kg of deionized water according to the ratio of material to liquid (w / v) 1:15, and homogenate for 25 minutes at a temperature of 30 °C and a speed of 10000 rpm. , the homogenate was detected by HPLC-RID method and the extraction rate of stachyose was 83.7%;

[0028] (2) Cloth bag filter: filter area 7m 2 , filter aperture 5um, filter pressure 0.3Mpa, water flow 10T / h. Obtain 1570 kilograms of filtrates after the slag material is separated;

[0029] (3) Decolorization of macroporous resin: at normal temperature, the filtrate is decolorized through a chromatographic column equipped with macroporous adsorbent resin at a flow rate of 2 column bed volumes / hour, and the sample loading is stopped when the processing capacity is 5 times of column bed volume , with 3 times the column bed volume top wash with deionized water, to get 1790 kg of decolorization solution;

[0030] (4) Ultrafiltrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com