Method for recovering silicon material from waste materials in cutting crystalline silicon by diamond wire

A diamond wire cutting, silicon material technology, applied in chemical instruments and methods, silicon compounds, non-metallic elements, etc., can solve the problems of lack of reasonable waste silicon material recycling and treatment methods, increase production costs of enterprises, environmental damage, etc. The effect of low cost, easy operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

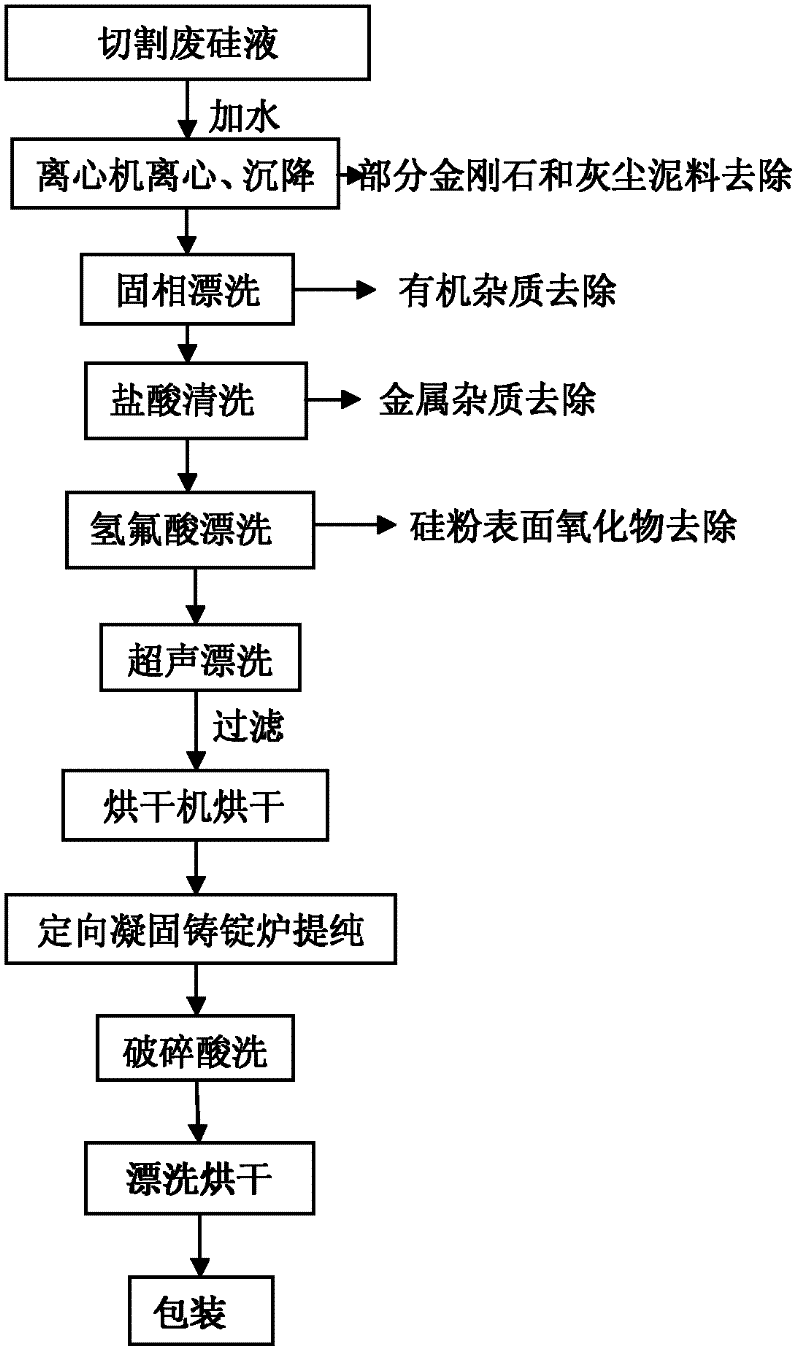

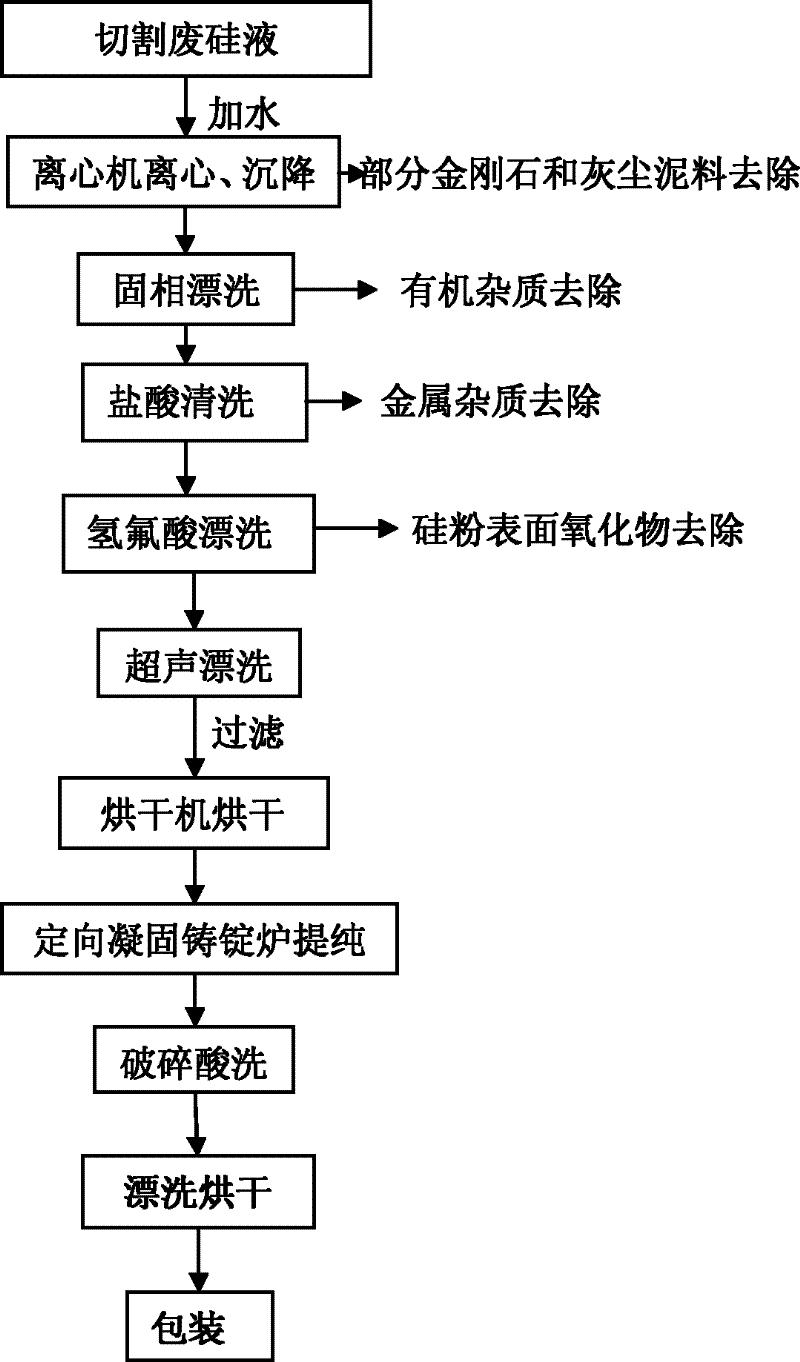

Method used

Image

Examples

Embodiment 1

[0022] Put the collected waste into a centrifuge for centrifugal sedimentation to obtain a silicon material precipitate. The precipitate is rinsed with pure water for 30 minutes at room temperature to remove organic matter in the residual liquid in the solid and obtain a certain purity of silicon powder. Then put the sorted solid-phase silicon powder into the hydrochloric acid aqueous solution with a concentration of 12%, soak for 2 hours while stirring to remove metal impurities, rinse with pure water, and then pass into an aqueous hydrofluoric acid solution with a concentration of 5%. In the process, soak the silicon material for 2 hours while stirring to remove the oxide on the surface of the silicon powder. Rinse and dry the reacted silicon material again. The rinsing method is ultrasonic rinsing in pure water at room temperature for 20 minutes, and the drying method is baking at 100°C for 3 hours, and the obtained silicon powder is directional solidified and cast into an i...

Embodiment 2

[0024] Put the collected waste into a centrifuge for centrifugal sedimentation to obtain a silicon material precipitate. The precipitate is rinsed with pure water and solid phase for 120 minutes at room temperature to remove the organic matter in the residual liquid in the solid and obtain a certain purity of silicon powder. Then put the sorted solid-phase silicon powder into the hydrochloric acid aqueous solution with a concentration of 17%, soak for 1.5 hours while stirring to remove metal impurities, rinse with pure water, and then pass through a 35% hydrofluoric acid aqueous solution During the process, soak the silicon material for 1.5 hours while stirring to remove the oxide on the surface of the silicon powder. Rinse and dry the reacted silicon material again. The rinsing method is ultrasonic rinsing in pure water at room temperature for 120 minutes, and the drying method is baking at 115°C for 2.5 hours. The obtained silicon powder is directional solidified and cast int...

Embodiment 3

[0026] Put the collected waste into a centrifuge for centrifugal sedimentation to obtain a silicon material precipitate. The precipitate is rinsed with pure water in solid phase for 240 minutes at room temperature to remove the organic matter in the residual liquid in the solid and obtain a certain purity of silicon powder. Then put the sorted solid-phase silicon powder into the hydrochloric acid aqueous solution with a concentration of 20%, soak for 1 hour while stirring, remove metal impurities, rinse with pure water, and then pass into a hydrofluoric acid aqueous solution with a concentration of 50%. In the process, soak and wash the silicon material for 1 hour while stirring to remove the oxide on the surface of the silicon powder. Rinse and dry the reacted silicon material again. The rinsing method is ultrasonic rinsing in pure water at room temperature for 240 minutes, and the drying method is baking at 130°C for 2 hours, and the obtained silicon powder is directional sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com