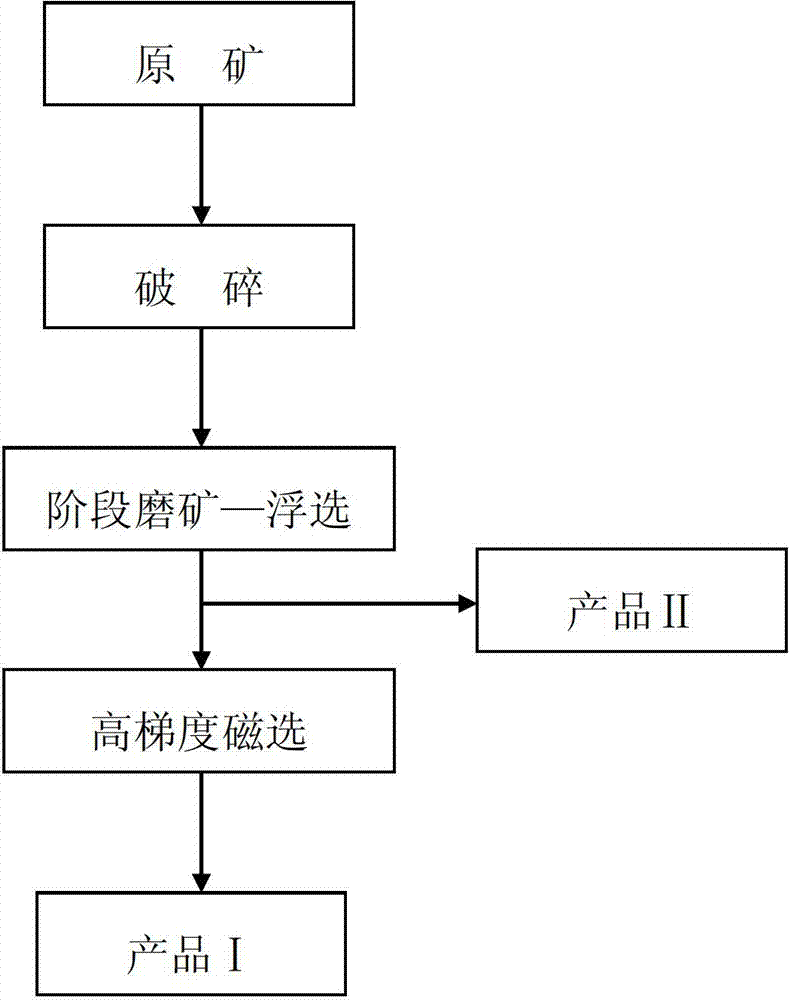

Low-grade aphanitic graphite dressing and purifying method

The technology of cryptocrystalline graphite and purification method is applied in the field of beneficiation and purification of low-grade cryptocrystalline graphite, which can solve the problems of high fixed carbon content, large environmental pollution and high processing cost, so as to improve the pulp environment and improve the flotation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

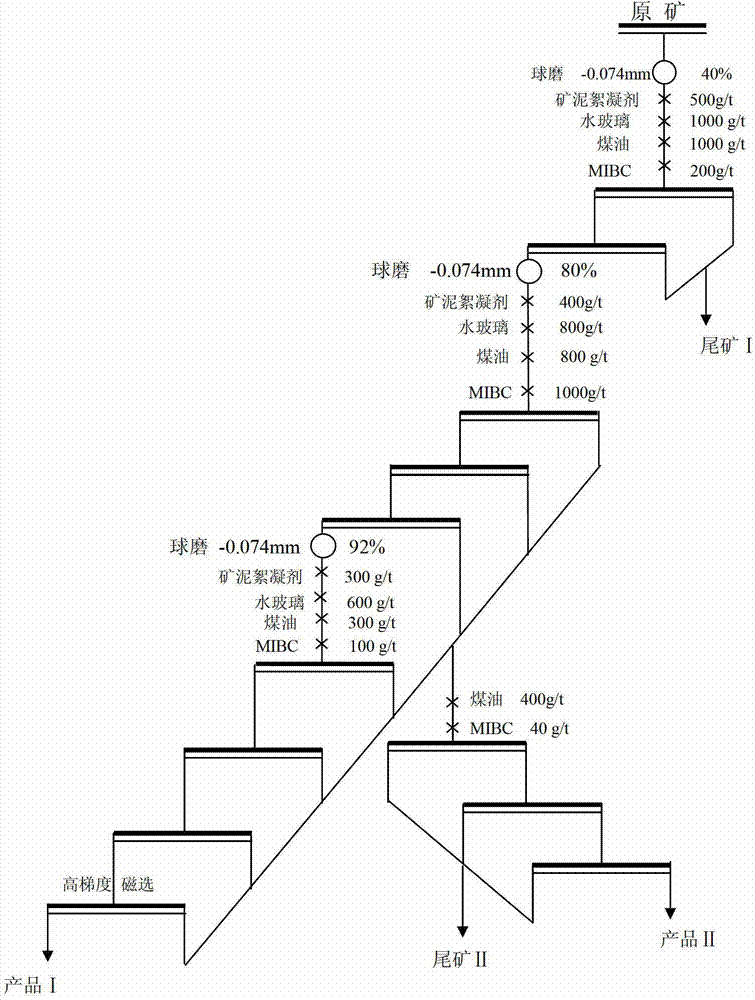

[0027] refer to figure 2 , to describe Embodiment 1 of the present invention in detail.

[0028] 1) The first stage of grinding - flotation

[0029] The aphanitic graphite raw ore with a fixed carbon content of 49.26% and an iron content of 2.307% is crushed to less than 0.5mm, the first stage of grinding, the fineness to -0.074mm accounts for 40%, and the grinding concentration is 50%; the first stage of grinding Add slime flocculant (a mixture of polyethylene oxide and acidified water glass at a mass ratio of 1:10) 500g / t, inhibitor water glass 1000g / t, collector kerosene 1000g / t to the ore pulp 1. The foaming agent MIBC is 200g / t, and it is stirred evenly in the stirring tank; the ore pulp after the action of the agent is passed into a mechanically stirred flotation machine for rough separation, and the rough concentrate is subjected to one beneficiation to obtain the first The first stage of grinding-flotation concentrate, the concentrate enters the second stage of grin...

Embodiment 2

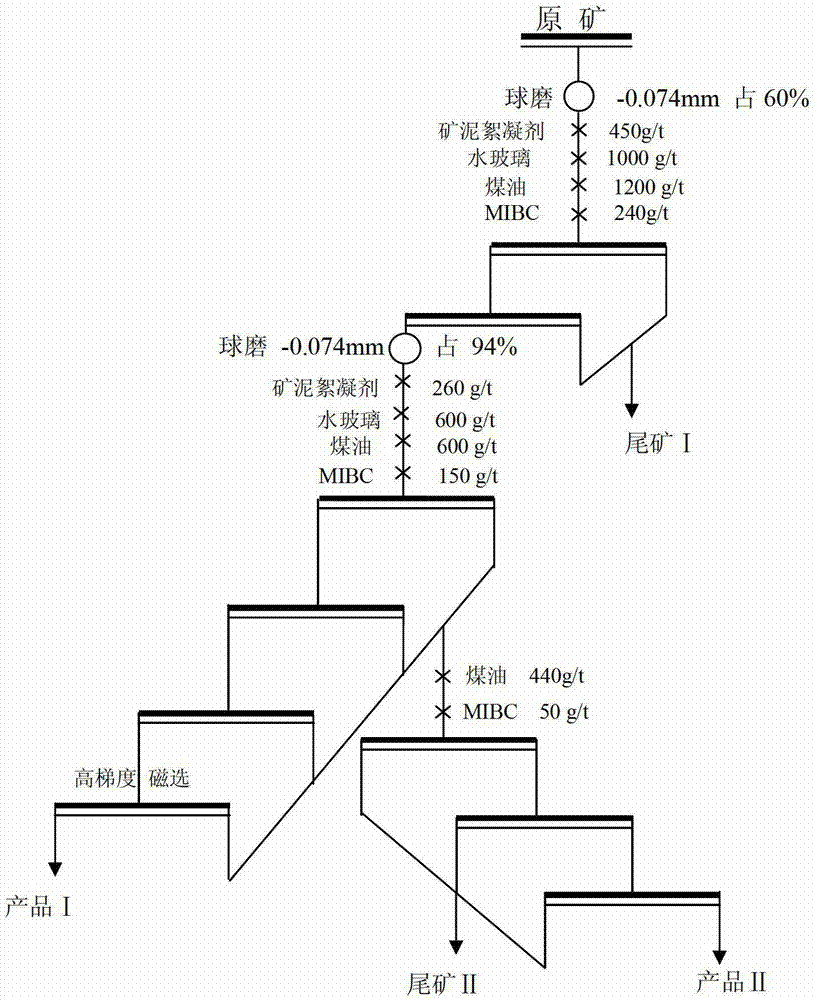

[0040] refer to image 3 , to describe Embodiment 2 of the present invention in detail.

[0041] 1) The first stage of grinding - flotation

[0042] The aphanitic graphite raw ore with a fixed carbon content of 63.52% and an iron content of 2.12% is crushed to less than 0.5mm, the first stage of grinding, the fineness to -0.074mm accounts for 60%, and the grinding concentration is 50%; the first stage of grinding Add slime flocculant (a mixture of polyethylene oxide and acidified water glass at a mass ratio of 1:10) 450g / t, inhibitor water glass 1000g / t, collector kerosene 1200g / t to the ore pulp , the foaming agent MIBC is 240g / t, and it is stirred evenly in the stirring tank; the ore pulp after the action of the agent is passed into a mechanically stirred flotation machine for rough separation, and the rough concentrate is selected once to obtain the first The first stage of grinding-flotation concentrate, the concentrate enters the second stage of grinding-flotation, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com