Method for reducing subsidence of stope overburden bed separation by grouting

A technology of layer separation and separation of overburden, applied in the field of coal mining, can solve problems such as low efficiency of separation and grouting and sedimentation reduction, and achieve the effects of saving equipment and engineering investment, improving recovery rate and improving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

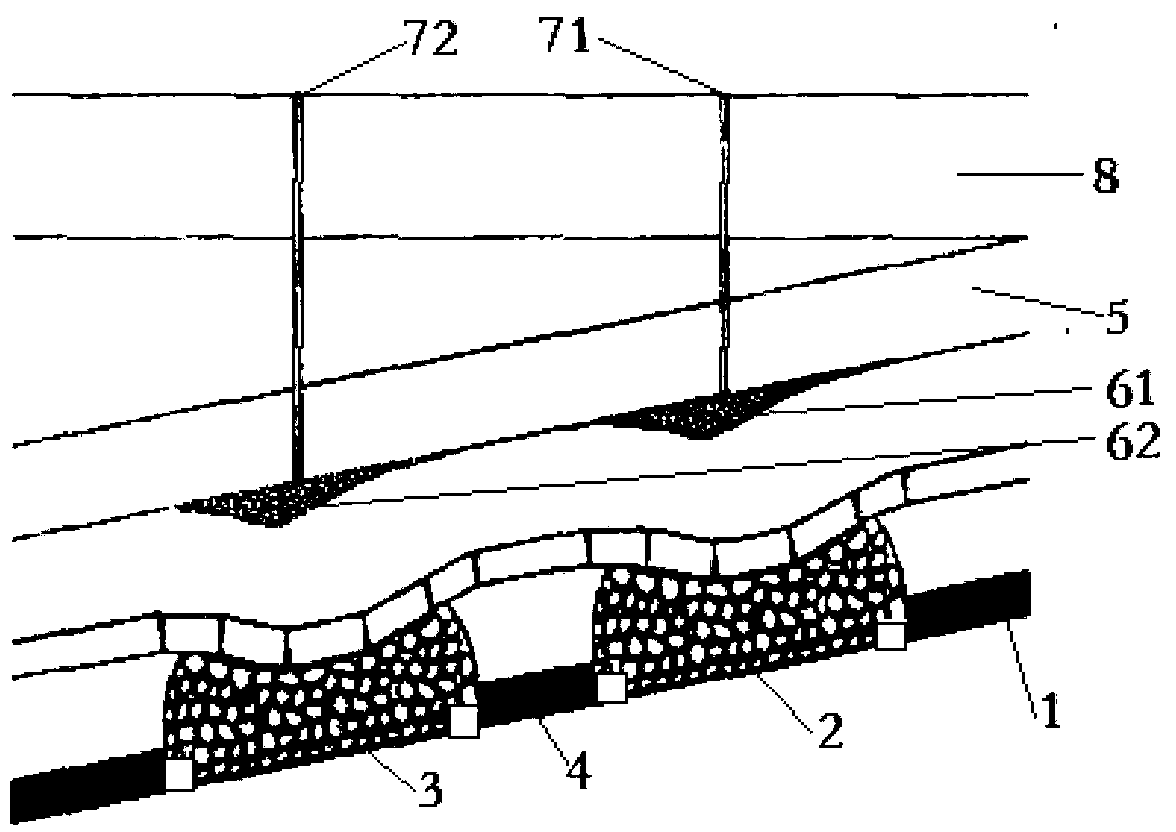

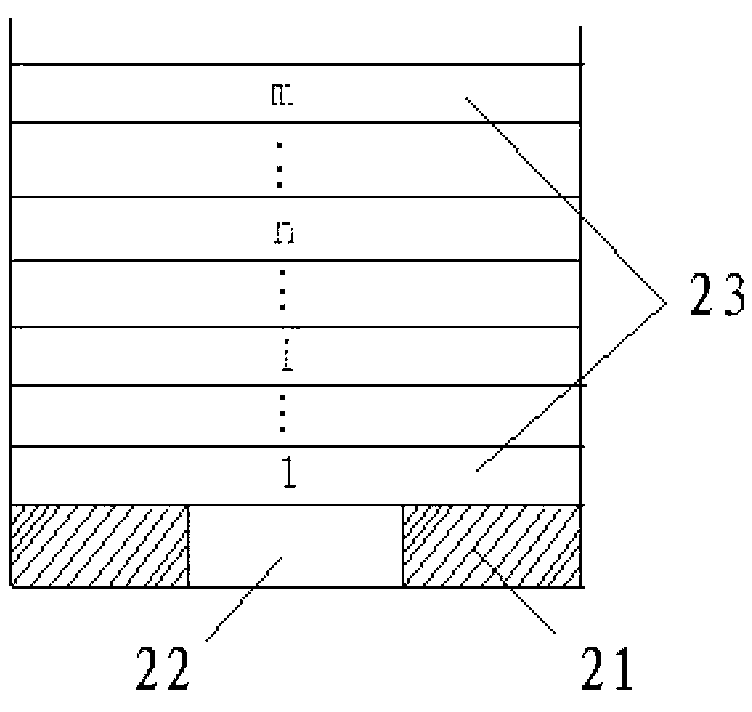

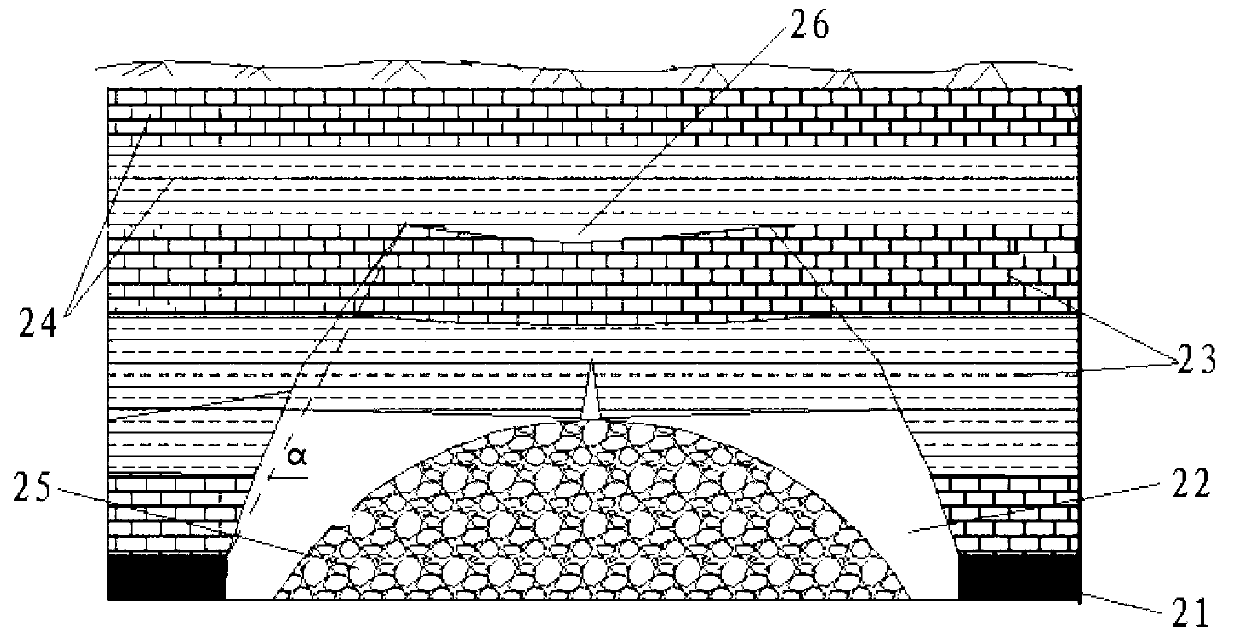

[0032] The invention provides a grouting method for reducing the settlement of the stope overlying rock with a tendency to separate layers. In the method of the invention, no coal pillars are adopted between the working faces, so that the goaf is continuous, and the grouting hole is used to reach the target. Separation layer grouting below the key layer, the target key layer refers to the key layer whose fracture and subsidence are controlled by grouting into the separation layer below it; and with the mining of the new continuous working face, the separation layer will extend When the separation layer expands, the grouting hole will continue to be filled through the grouting hole, and the continuous goaf will be easier to achieve full mining, so that the separation layer will be more fully grouted, and the grouting will be more efficient after grouting. Stablize.

[0033] Step 1: According to geological exploration data, determine all key layers above the stope.

[0034] Usu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com