Pressure relief presplitting blasting gob-side entry retaining pillar-free mining method

A technology of pre-split blasting and mining methods, applied in ground mining, mining equipment, earth-moving drilling and other directions, can solve problems such as roadway deformation and roadway maintenance difficulties, reduce maintenance costs, improve resource recovery rate, and facilitate maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Diamond Coal Mine is located in Shiban Town, Dazhou City, Sichuan Province, 27km away from Dazhou and about 30km away from Dazhou Railway Station.

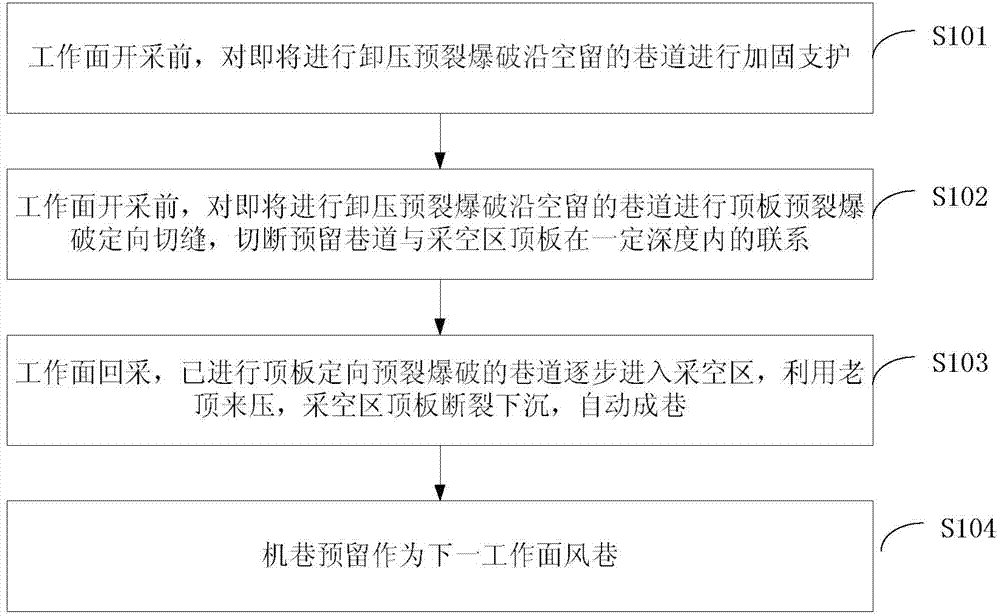

[0057] The construction process of pressure-relieving pre-splitting blasting in gob-side entry retaining without coal pillars is as follows:

[0058] (1) The first mining face is constructed along the groove from top to bottom.

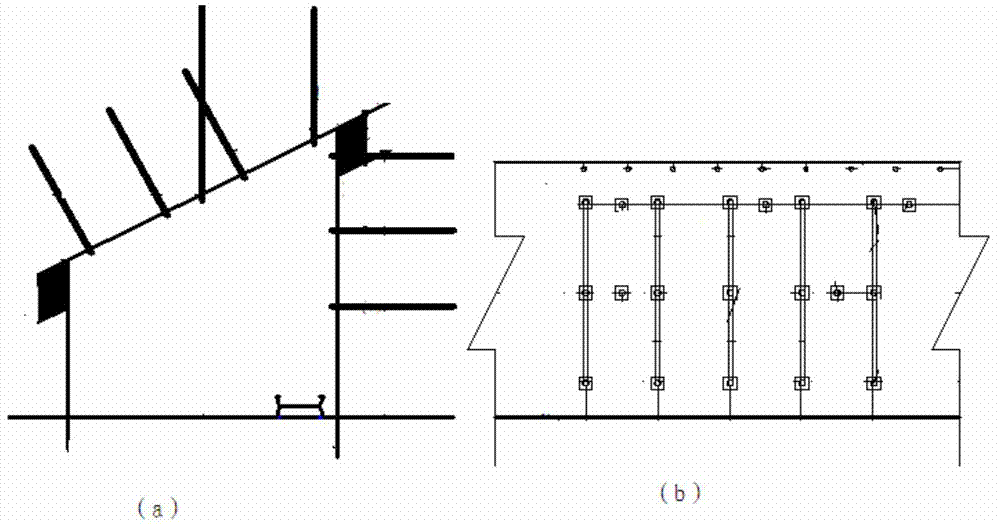

[0059] (2) Anchor cable construction at the working face along the trench 50m ahead.

[0060] (3) Lag face 2-5m construction pre-splitting blast hole.

[0061] (4) 5-10 blastholes are constructed each time. After the blastholes are constructed, they are charged and blasted in time, and 5 blastholes are blasted each time. Each blast hole shall be inspected by the blaster before charging each time. If the blast hole is affected by the mining pressure and cannot be filled with shaped charges, the blast hole must be cleaned; the length of the mud seal after charge shall not be less than 1.0m.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Preload | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com