Method for taking out and picking high gassy seam group dislodging gob-side entry retaining Y type ventilated decompression firedamp

A technology of gas drainage and coal seam group, which is applied in the direction of gas discharge, mining equipment, earthwork drilling, etc., can solve the problems of low drilling rate of drainage drilling, low pre-drainage rate, and easy collapse of drilling holes, etc., to achieve Eliminate the dangerous threat of coal and gas outburst, solve the gas overrun and gas accumulation, and solve the effect of gas overrun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

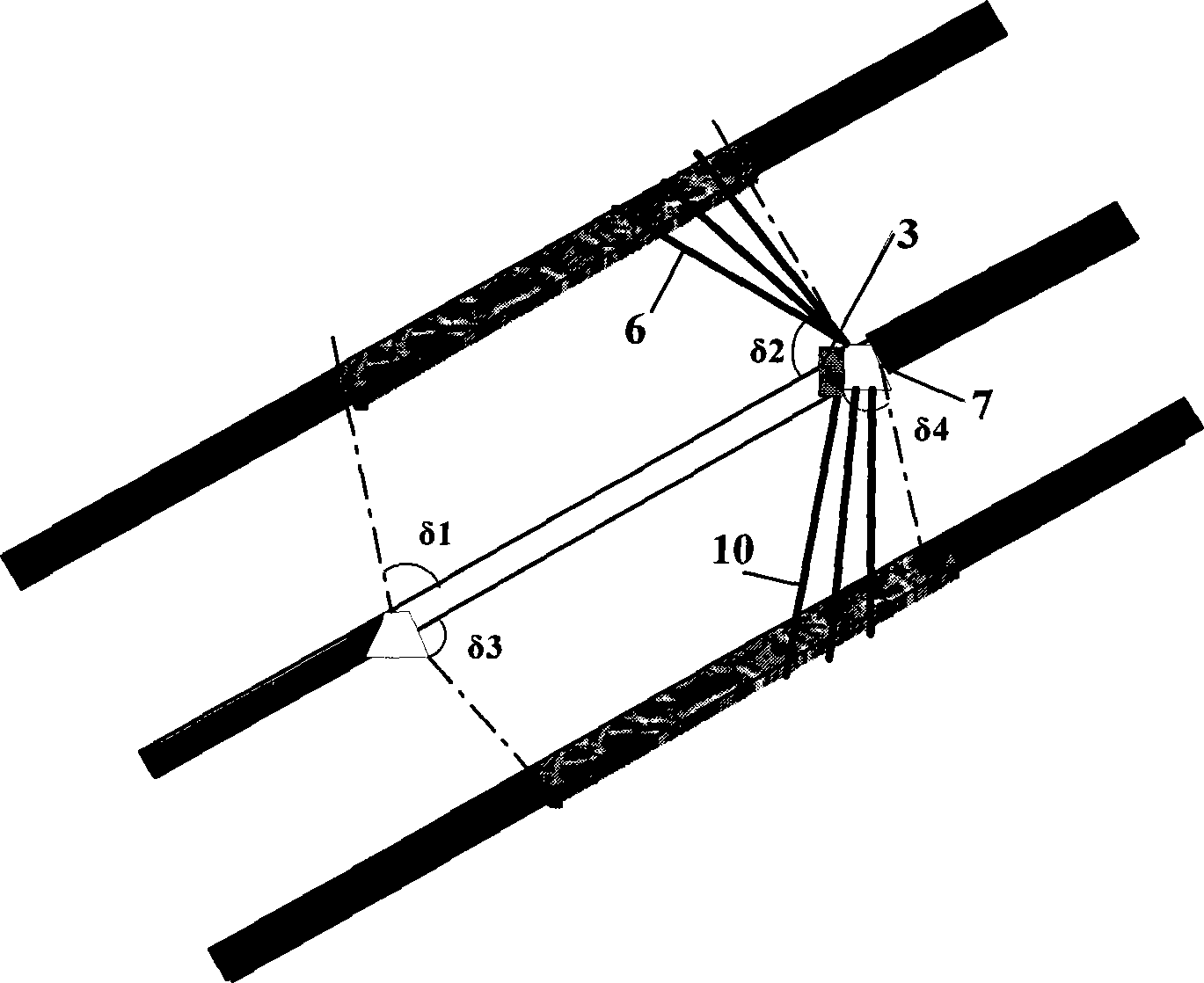

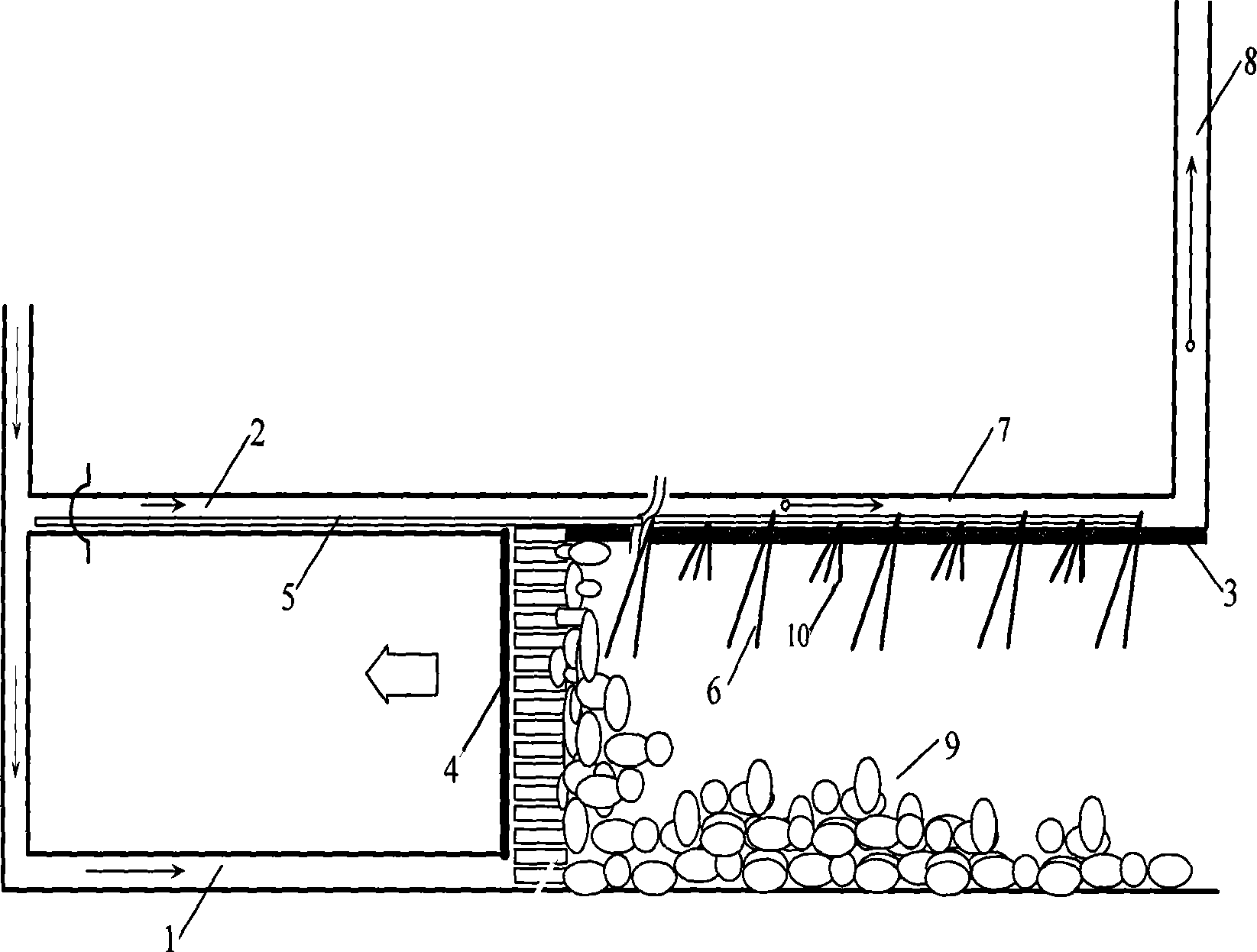

[0018] See figure 1 , figure 2 In the first mining coal seam of high gas coal seam group, the roof pressure relief area and floor pressure relief area of the goaf are left along the goaf. For the adjacent pressure relief layers, the roof and floor coal beds of the goaf are mined. The fissure channels formed by the dynamic influence converge to the desorbed free gas in the roof pressure relief fracture ring and the floor pressure relief fracture ring, and the upward gas drainage boreholes respectively arranged in the roof pressure relief fracture ring are arranged in the roadway along the goaf 6 And the downward gas drainage borehole 10 arranged in the bottom pressure relief crack circle. The roof pressure relief crack area is located above the roof caving zone of the Y-shaped ventilation working face along the goaf. The mining affects the crack zone. In the coal seam of the depressurization and bending subsidence zone, the floor pressure relief crack circle is located in the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com