Non-pillar mining method for hard roof coal wall of thick coal seam

A hard roof and mining method technology, which is applied in ground mining, earth drilling, underground mining, etc., can solve problems such as excessive deformation, large suspended roof area, hard roof that is hard to collapse, etc., and achieves small deformation and high safety , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

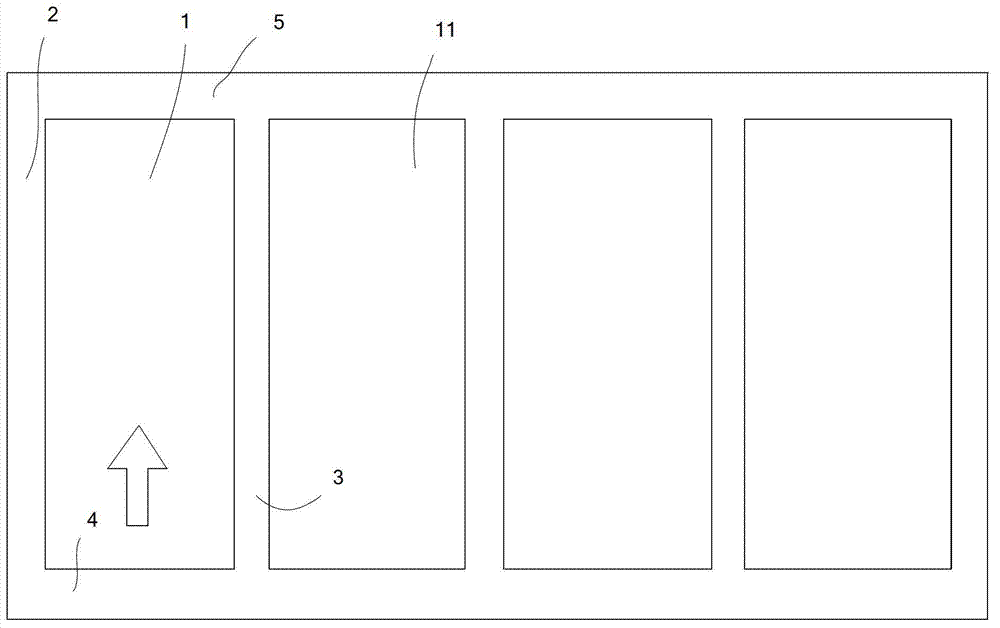

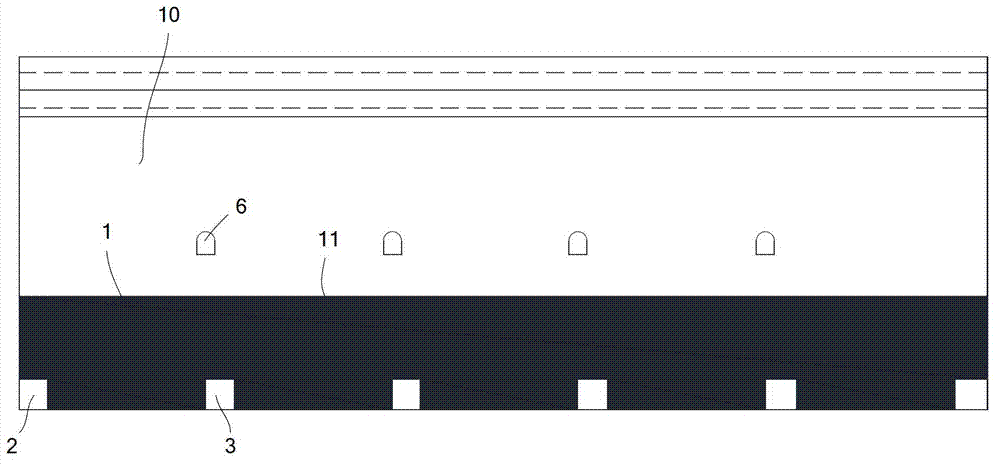

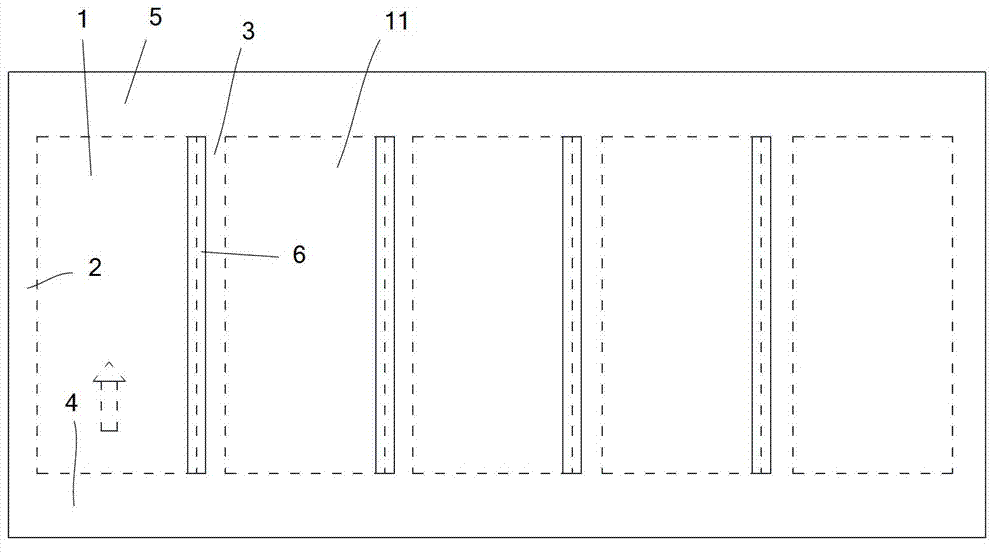

Image

Examples

Embodiment approach

[0045] The coal seam inclination angle of the working face is 5-10 degrees, the working face is 352 meters long, 1050 meters long, and 700 meters deep. It belongs to the coal of the Carboniferous Permian Xishan Formation, and the mining thickness is 4.0 meters. Large mining height and full-height longwall retreating comprehensive mechanized mining is adopted in one-time mining, and the roof is managed by the caving method. Among them, the machine lane is 1050 meters long and has a special-shaped section. The lane is 2.5 meters high and 3.6 meters wide. During the test period, the working face was mined 300 meters, and after experiencing multiple occurrences of mine pressure, a total of 280 meters of roadway was formed. 3.5 meters, and according to field observations, the gangue cut from the side of the roadway is full of gangue and the roof is connected within 90 meters after mining. Outside the side, the average value of convergent deformation of the top and bottom plates is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com