Coal mining method with direct coal pillar recovery

A coal mining method and coal pillar technology, applied in the field of coal pillar direct recovery coal mining method, can solve problems such as low resource recovery rate, achieve large roadway deformation, avoid waste of resources, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

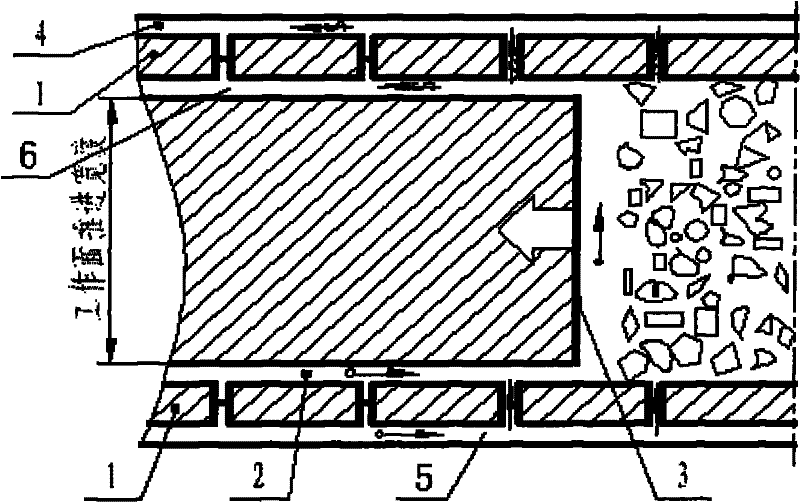

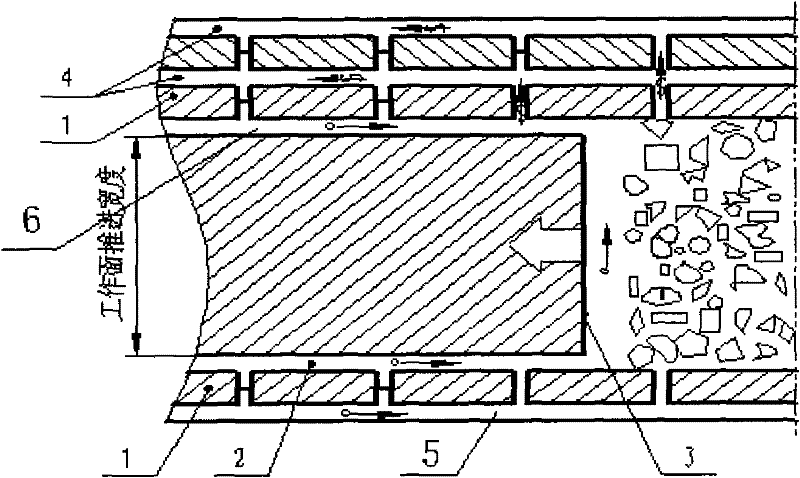

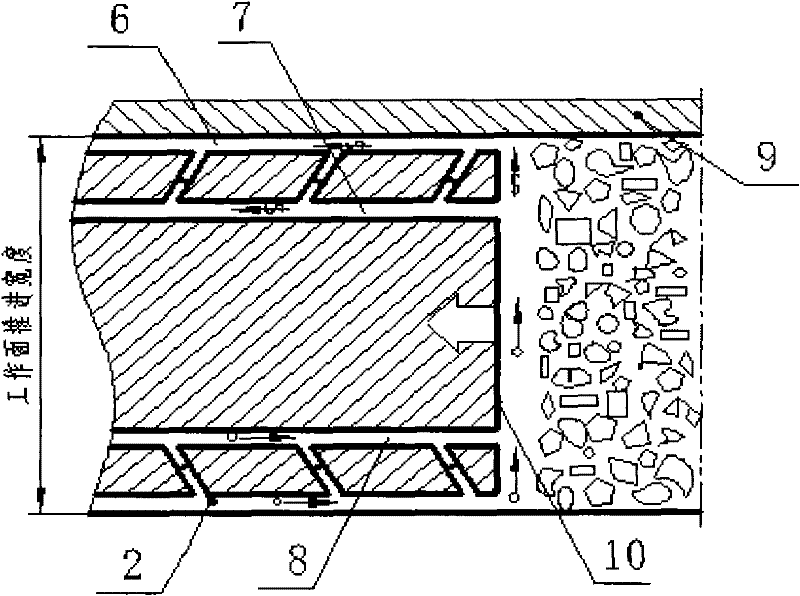

[0021] Such as figure 1 As shown, a coal mining method for direct recovery of coal pillars, specifically:

[0022] 1. On both sides of the large-width working face 10 of coal mining, set up a trough roadway 2 and 6, one of which is used as a belt transport and air inlet lane 2, and the other is used as a return air lane 6 or an air inlet lane according to the design of the ventilation system ; The two outer sides of the tunnel roadway 6 are left as continuous isolated coal pillars 9,

[0023] 2. Arrange the rest of the ventilation lanes and auxiliary lanes 8 and 7 between the two sides of the above-mentioned working face along the trough lanes 2 and 6 according to the needs. Coal pillars and corresponding ventilation methods,

[0024] 3. Arrange coal mining equipment in front of the large-width working face 10 between the two down-trough roadways 2 and 6: scraper conveyor and coal shearer 13,

[0025] 4. Manipulate the shearer 13 to cut coal from one side of the large-width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com