Method for reclaiming house type remaining coal pillars based on filling and rebuilding of entry protection coal-pillar band

A technology for leaving coal pillars and coal pillars, applied in the fields of filling, earthwork drilling, surface mining, etc., can solve the problems affecting the safety of people's lives and property in the mining area, waste of precious and high-quality national resources, and waste of resources, so as to reduce the surface subsidence. , to improve resource utilization, the effect of high regeneration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

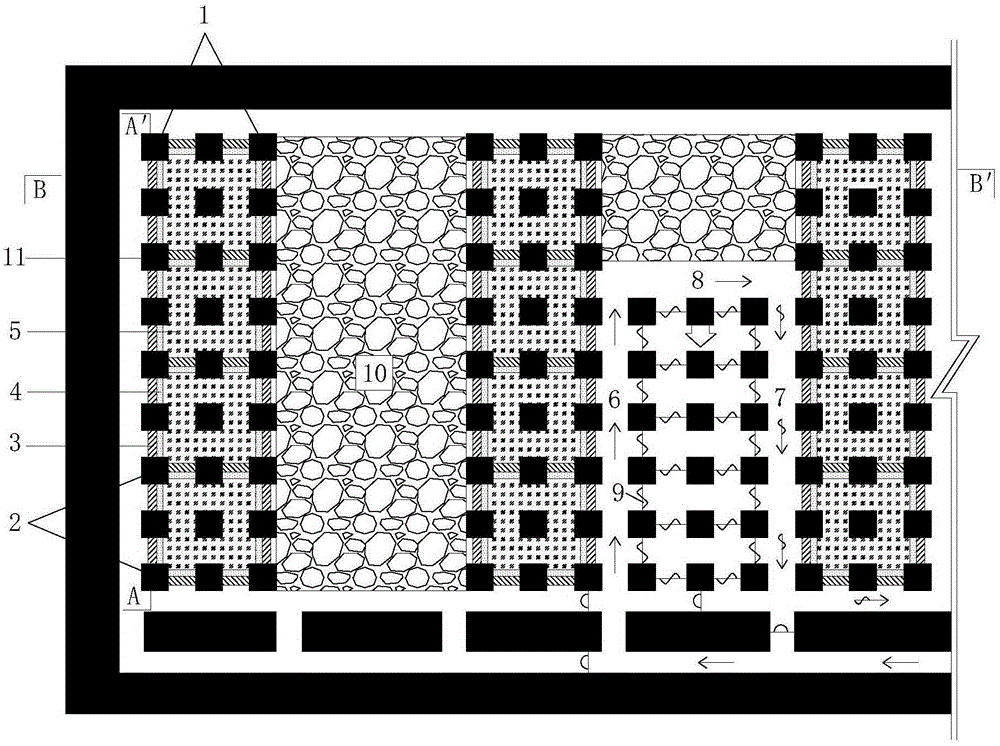

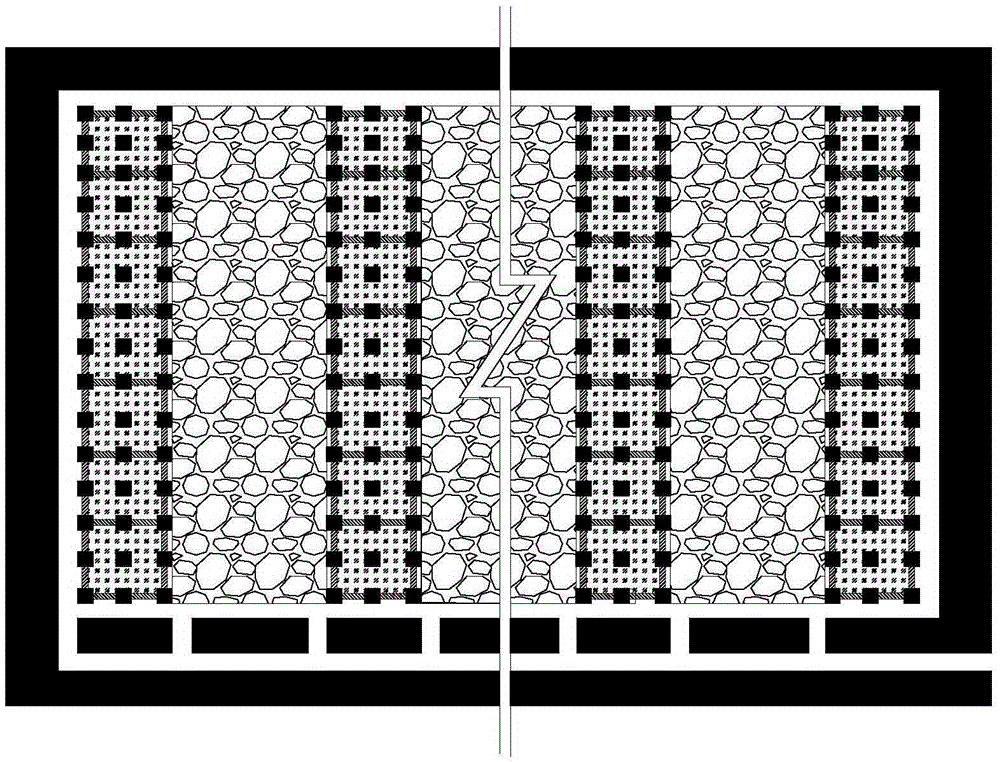

Embodiment 1

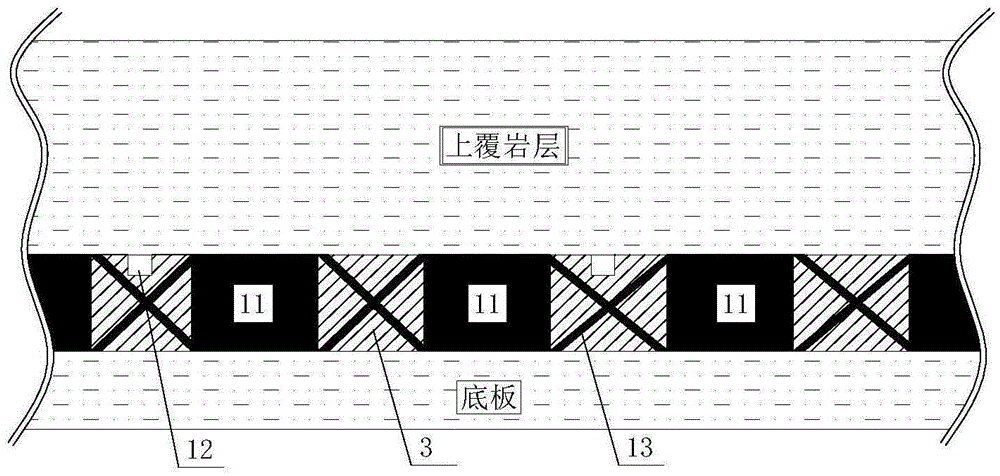

[0029] Example 1: The inclination angle of the coal seam in a mine is 2-5°, the average buried depth is 100m, and the average thickness is 2.7m. The roof is a stable roof. In the early days, the room type coal mining method was used for mining, and the size of the mining coal room was 7×7×4.5m , the size of the remaining coal pillar is 9×9×4.5m. The width-to-height ratio of the remaining coal pillars in the goaf is calculated to be 3.3, and the remaining mining ratio is 0.46.

[0030] (1) According to the occurrence conditions of the remaining coal pillars 11 in the goaf on site, the three key factors of the roof stability, width-to-height ratio and mining ratio of the remaining coal pillars 11 are brought into the stability of the remaining coal pillars in the goaf Classification table, conduct comprehensive evaluation and determine that the stability grade of the left coal pillar in the goaf is stable;

[0031] (2) According to the stability grade of the remaining coal pill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com